Internal welded radiator header tube hole punched device and process thereof

A technology for punching devices and radiators, which is applied in the direction of punching tools, feeding devices, positioning devices, etc., which can solve the problems of easy safety accidents for operators, difficulty in product quality assurance, and high labor intensity of workers, so as to improve production labor. High efficiency, improved production environment, and fast transition time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

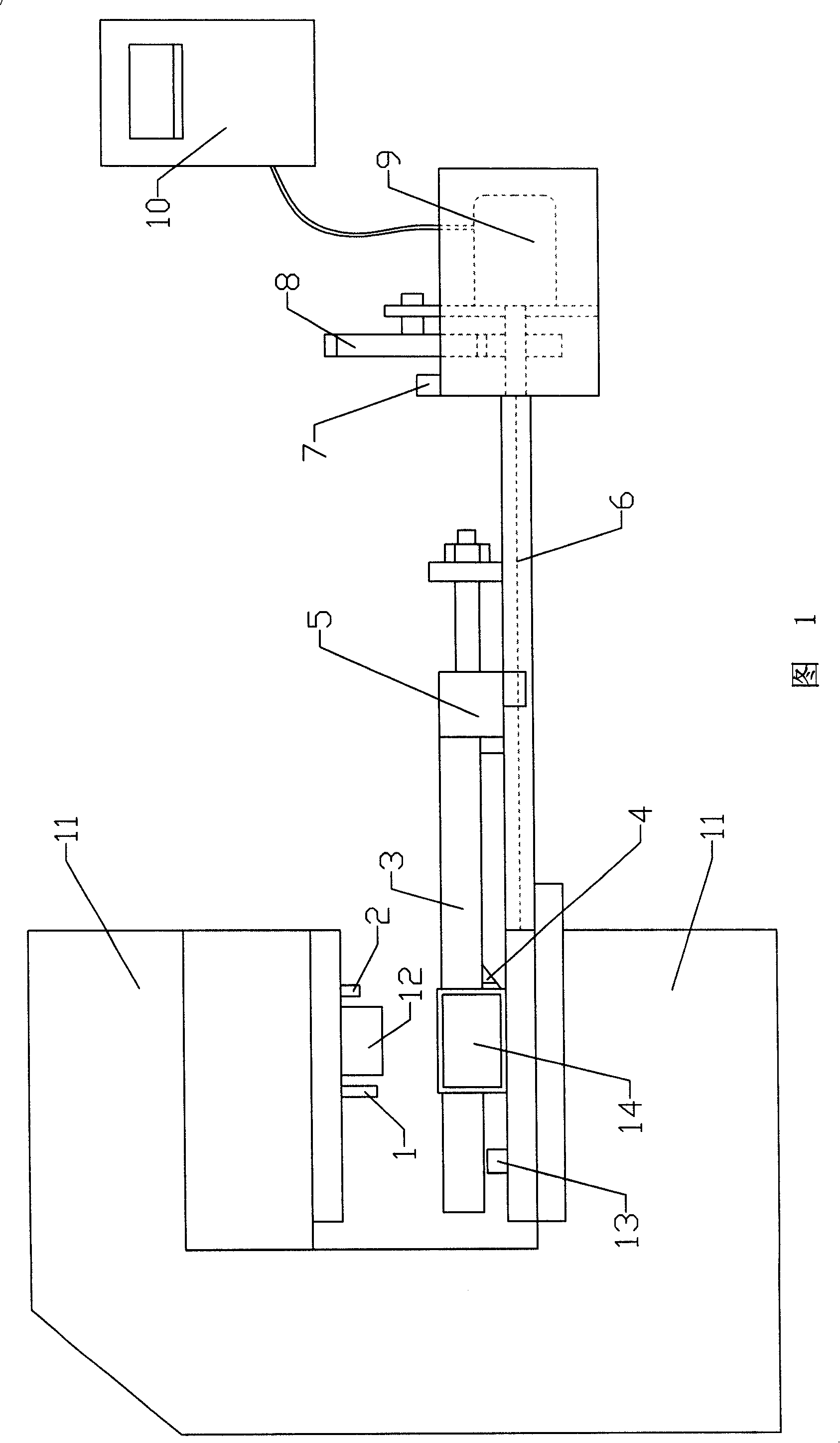

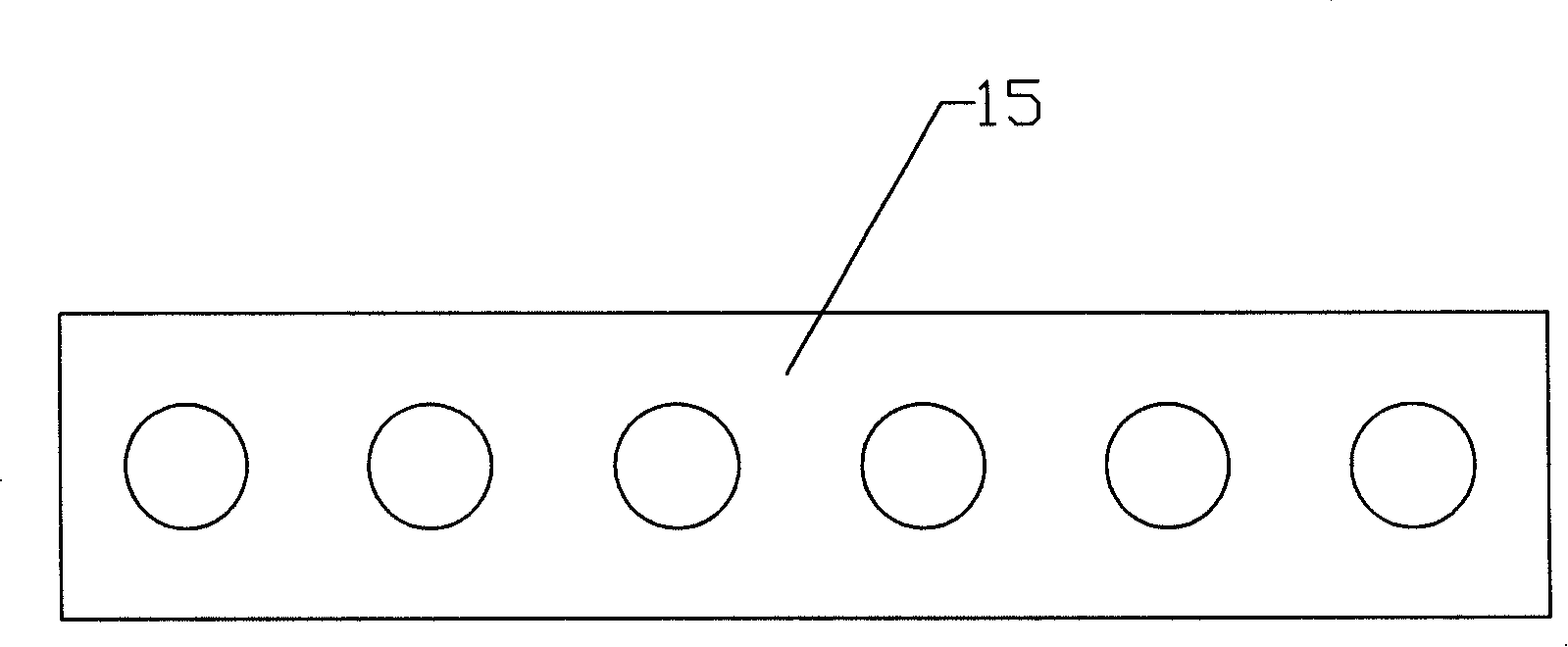

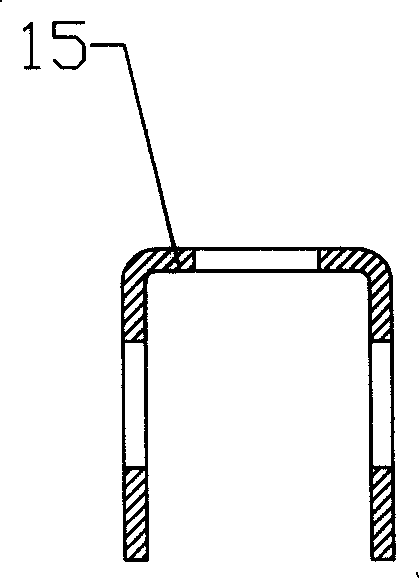

[0022] Embodiment, as shown in Figure 1, figure 2 , image 3 As shown, a punching device for an inner welded radiator header pipe includes a punching machine 11, a control cabinet 10 and a feeding device. Into the motor 9, one end of the lead screw 6 is fixedly supported on the working platform of the punch press 11, and the other end is connected to the stepping motor 9, and the stepping motor 9 is electrically connected to the control cabinet 10. The working of the punch press 11 A stamping die is provided on the platform, and the support frame 5 and the stamping die are on the same horizontal plane. A lead screw rotates a large gear 8 between the stepper motor 9 and the lead screw 6, and the lead screw rotates a large gear 8 is connected with the stepper motor 9 by belt transmission, and the lead screw rotates the large gear 8 to mesh with the lead screw 6. The stamping die includes a lower die on the working platform of the punch press 11 and an upper die corresponding to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com