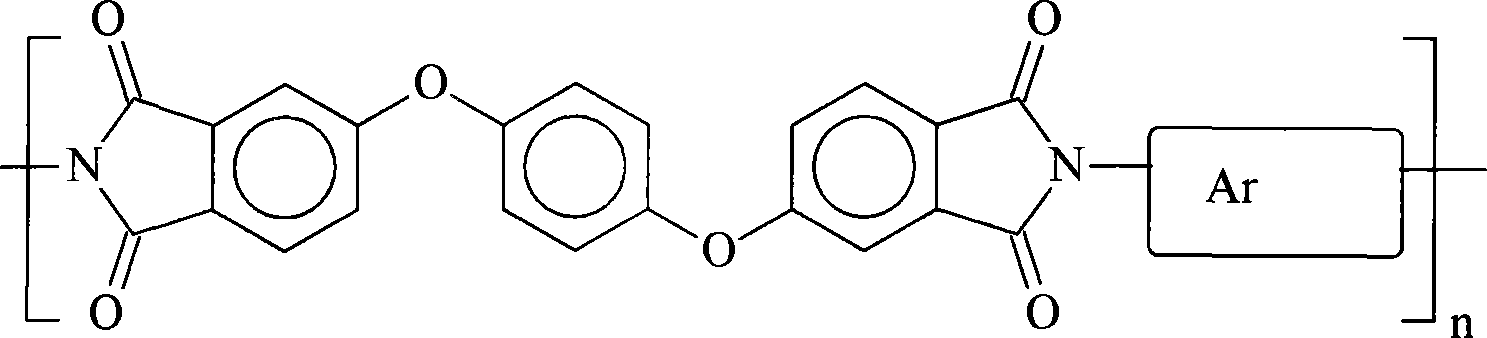

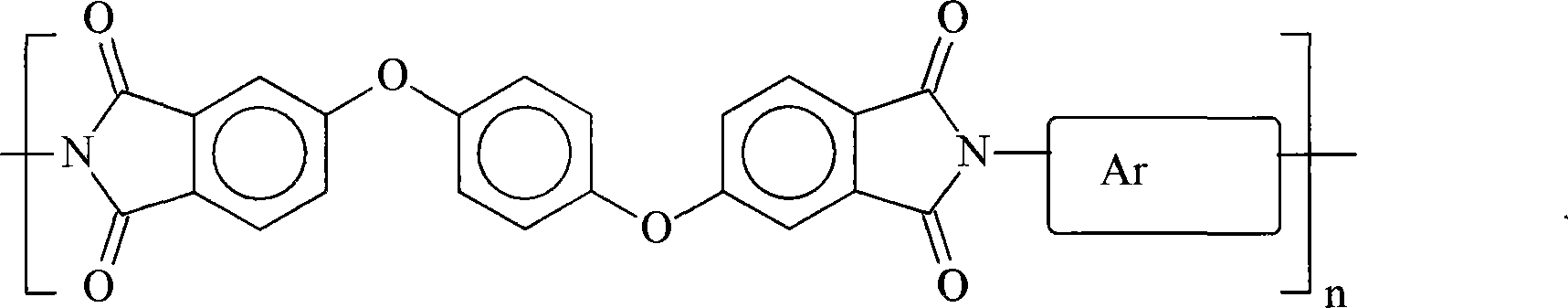

Flexible transparent polyimide film material and method for producing the same

A technology of transparent polyimide and film materials, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of poor mechanical strength of polyimide films and achieve good light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 Dissolve 6.4052 g of TFDB (0.02 mol) into 57.8 g of dimethylacetamide at room temperature, mechanically stir until TFDB is completely dissolved, then add 8.0464 g of HQDPA (0.02 mol) to the above solution under stirring. Stirring was continued for 48 hours to form a polyamic acid paint with a solid content of 20 wt%.

[0023] Place the formed polyamic acid paint statically for 24 hours until the air bubbles are eliminated, cast it on a clean glass plate, put it in a drying film box and bake it at 80°C for 2 hours, and after the solvent evaporates and the film is cured, apply the polyamic acid paint The glass plate of the polyimide film is moved into a high-temperature oven, and the high-temperature oven is processed from room temperature to 350° C. at a heating rate of 2° C. / min. Then turn off the high-temperature oven and make the temperature drop to room temperature naturally, take out the glass plate coated with polyimide from the oven, put it into water an...

Embodiment 2

[0024] Example 2 Dissolve 4.5266 g of DMMDA (0.02 mol) into 50.3 g of dimethylformamide at room temperature, mechanically stir until DMMDA is completely dissolved, then add 8.0464 g of HQDPA (0.02 mol) to the above solution under stirring. Stirring was continued for 48 hours to form a polyamic acid paint with a solid content of 20 wt%.

[0025] Place the formed polyamic acid paint statically for 24 hours until the air bubbles are eliminated, cast it on a clean glass plate, put it in a drying film box and bake it at 80°C for 2 hours, and after the solvent evaporates and the film is cured, apply the polyamic acid paint The glass plate of the polyimide film is moved into a high-temperature oven, and the high-temperature oven is processed from room temperature to 350° C. at a heating rate of 2° C. / min. Then turn off the high-temperature oven and make the temperature drop to room temperature naturally, take out the glass plate coated with polyimide from the oven, put it into water ...

Embodiment 3

[0026] Example 3 Dissolve 4.9662 grams of DDS (0.02mol) into 52.1 grams of γ-butyrolactone at room temperature, and stir mechanically for 2 hours. After the DDS is completely dissolved, add 8.0464 grams of HQDPA (0.02mol ). Stirring was continued for 48 hours to form a polyamic acid paint with a solid content of 20 wt%.

[0027] Place the formed polyamic acid paint statically for 24 hours until the air bubbles are eliminated, cast it on a clean glass plate, put it in a drying film box and bake it at 80°C for 2 hours, and after the solvent evaporates and the film is cured, apply the polyamic acid paint The glass plate of the polyimide film is moved into a high-temperature oven, and the high-temperature oven is processed from room temperature to 350° C. at a heating rate of 2° C. / min. Then turn off the high-temperature oven and make the temperature drop to room temperature naturally, take out the glass plate coated with polyimide from the oven, put it into water and boil the wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com