Electric hydraulic pressure workover treatment machine

A working machine and hydraulic technology, applied in drilling equipment, drilling equipment and methods, earthwork drilling, etc., can solve problems such as poor heat dissipation of drawworks brake hubs, hidden dangers of safety accidents at lowering speed, and waste of equipment capacity, and achieve energy utilization. and high work efficiency, obvious energy saving effect, and ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

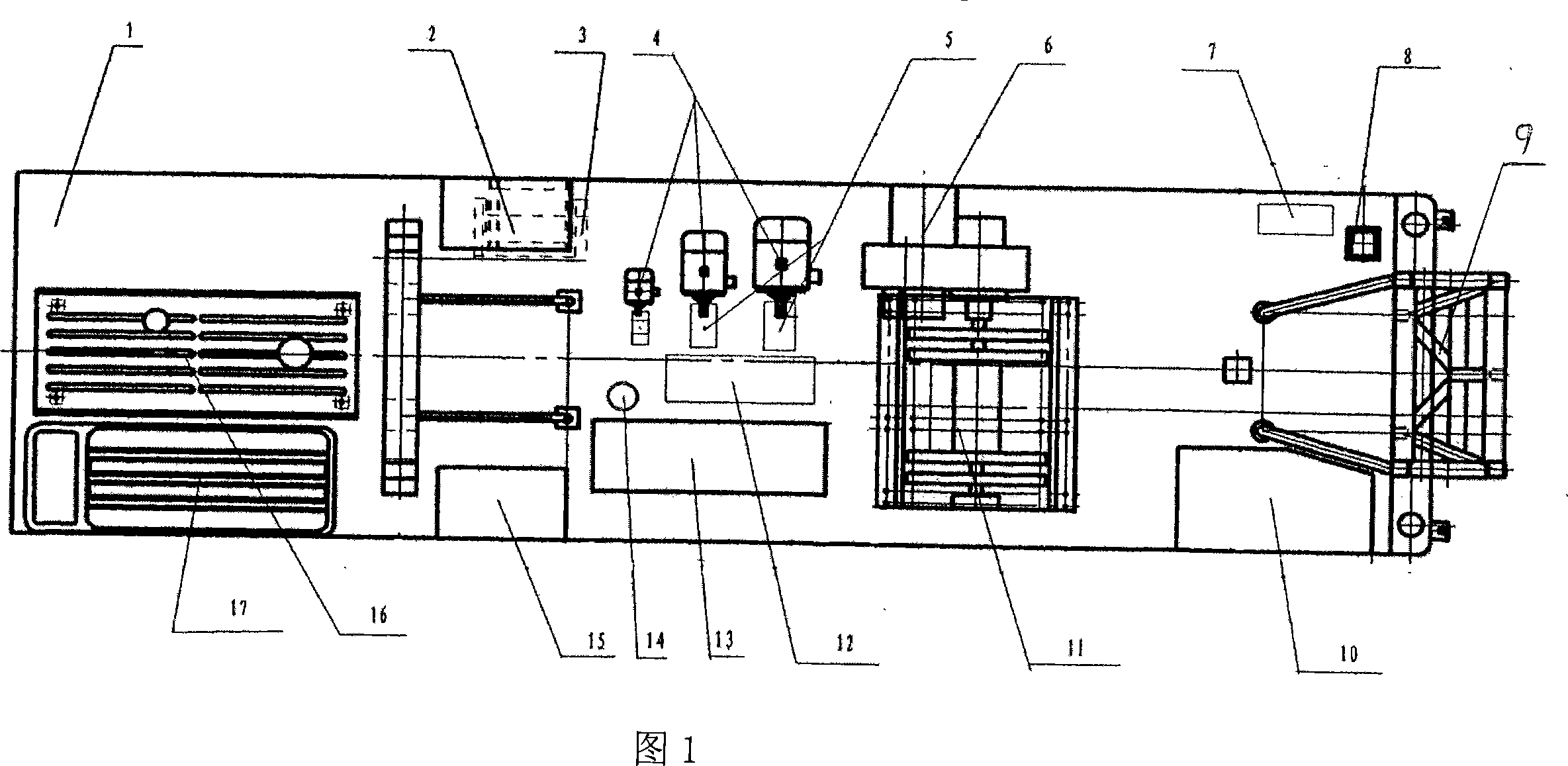

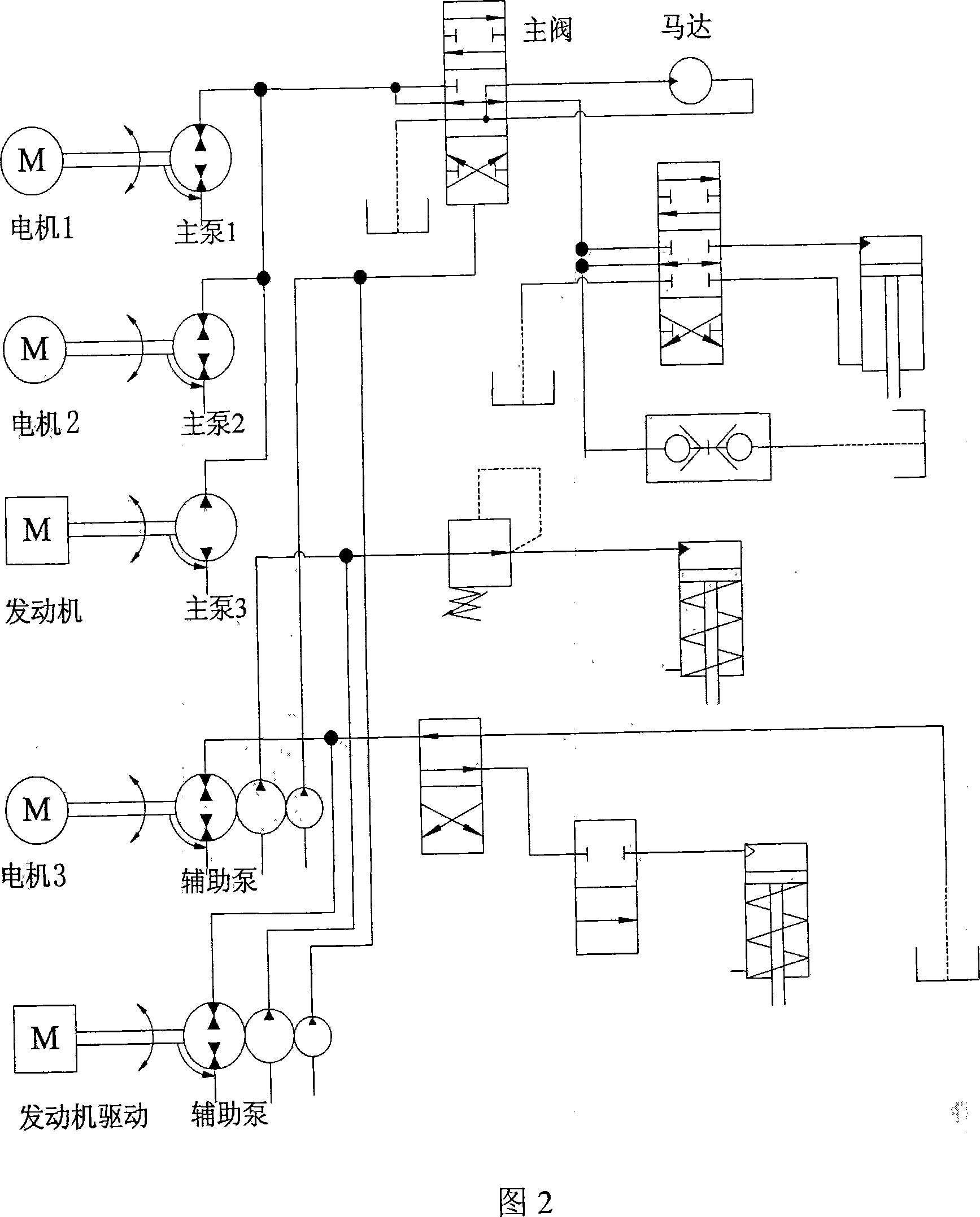

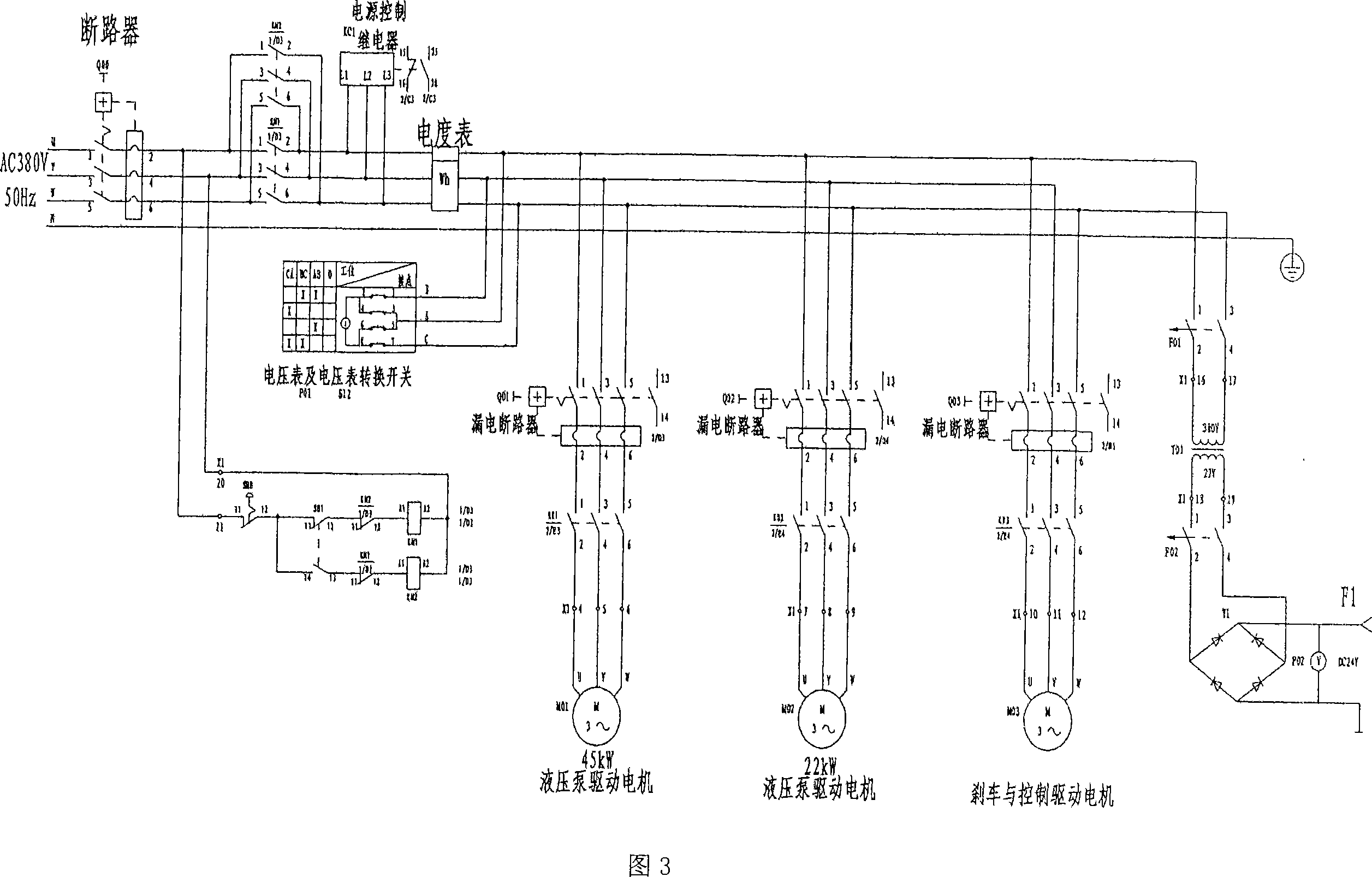

[0016] As shown in the figure, the present invention consists of a bottom car 1, an electrical cabinet 2, 15, a cable reel 3, a motor 4, a hydraulic pump 5, a gearbox and a hydraulic motor 6, a multi-way reversing valve 7, a small hydraulic winch 8, and a derrick and swimming system 9, operating room 10, winch 11, control valve group 12, hydraulic oil tank 13, accumulator 14, undercarriage engine 16, driver's cab 17, braking system, electric control system and auxiliary system, its structure , The assembly relationship is as follows: the winch 11 is arranged at the middle and rear part of the bottom car, and one side thereof is provided with a gearbox, a hydraulic motor 6 and a multi-way reversing valve 7, a derrick and a swimming system 9, an operating room 10 and a small hydraulic winch 8 respectively. It is arranged at the rear of the undercarriage. The front part of the undercarriage is provided with a driver's cab 17 and an engine 16. The two sides of the rear are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com