Method for predicting creep life of power boiler heatproof material

A technology of heat-resistant materials and creep life, which is applied in the field of creep life prediction of heat-resistant materials for power plant boilers, can solve the problems affecting the long-term operation safety of power plants, the inability to accurately predict the creep life of power plant boiler pipes, and the lack of creep fracture physics. theoretical basis and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

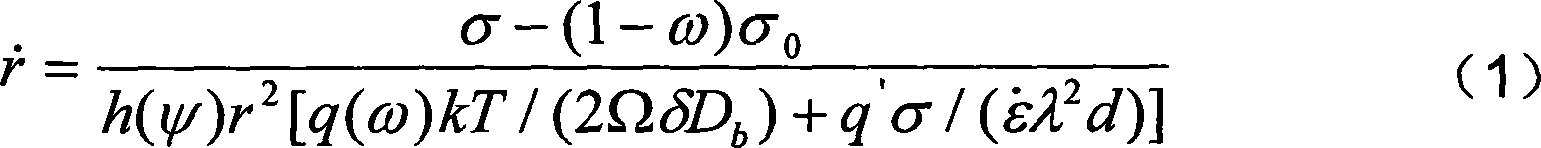

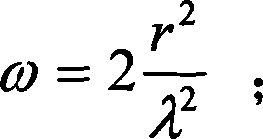

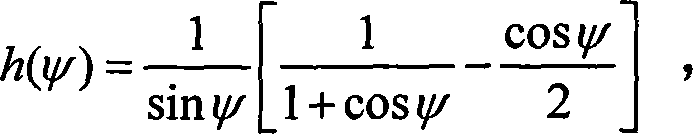

Method used

Image

Examples

Embodiment Construction

[0047] To consider the cavity nucleation mechanism of the actual fractured sample, it is necessary to consider that the creep cavity nucleation site includes the "ridge" on the grain boundary, the intersection of the triangular grain boundary, the intersection of the slip plane and the grain boundary, and the inclusion objects, carbides on grain boundaries, etc. Experiments have observed that voids can be coarse on inclusions and grain boundaries. 23 C 6 nucleation on the upper surface; inclusions are weakly combined with the matrix, and become the preferential position for cavity nucleation; during the creep process, M 23 C 6 Coarsening occurs, and the rarely dissolved impurities in the carbide are repelled to the interface, reducing the interface energy between the carbide and the matrix, promoting the separation of the carbide and the matrix, and the cracking of the carbide itself will also become the nucleation core of the cavity.

[0048] Microscopically observe and me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com