Production method of LED chip for illumination

A technology of LED chip and manufacturing method, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as difficult to overcome LED chip defects, difficult product integration, and complicated packaging process, so as to improve LED light output rate and reduce total reflection loss, the effect of encapsulation process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

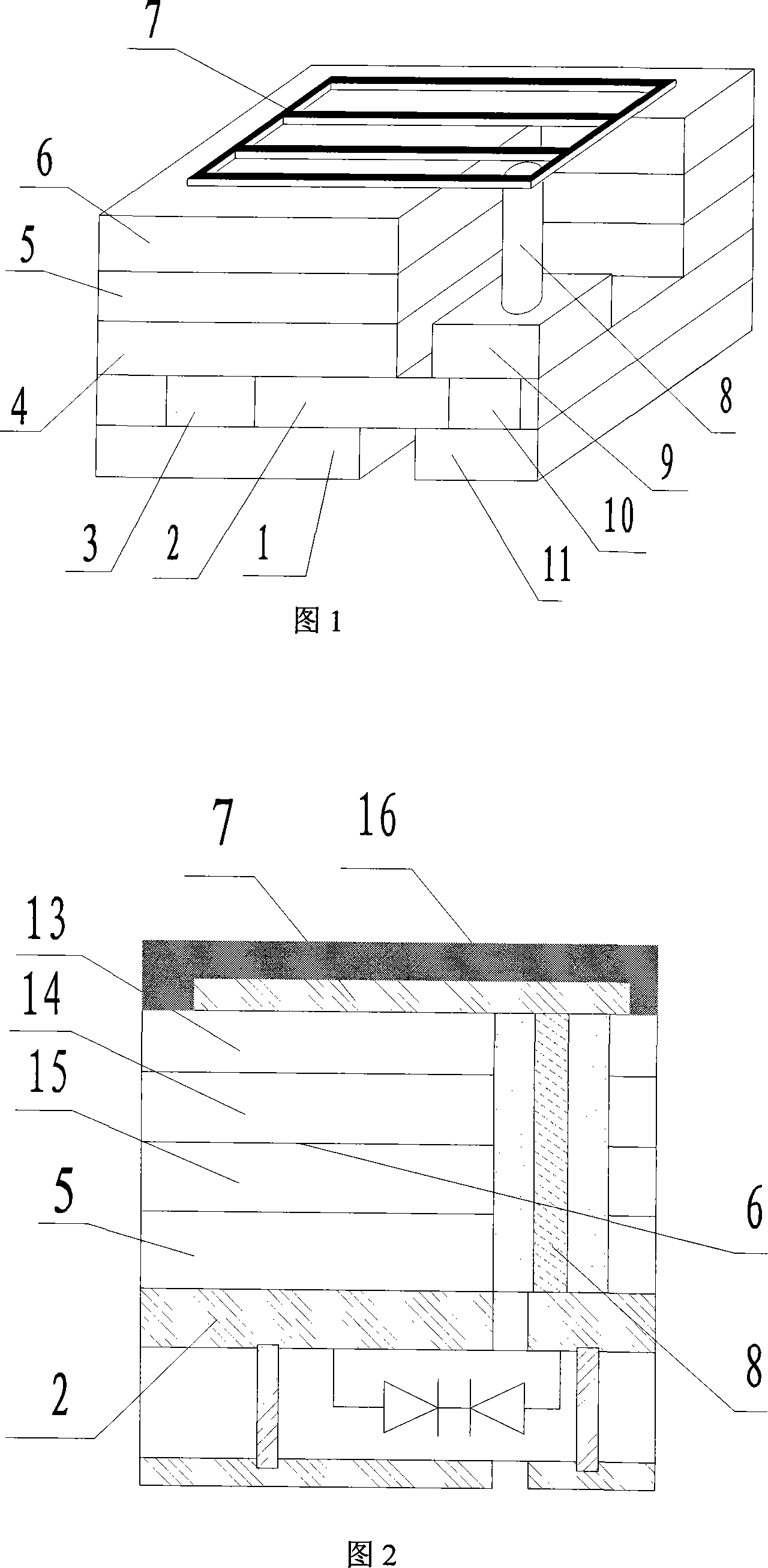

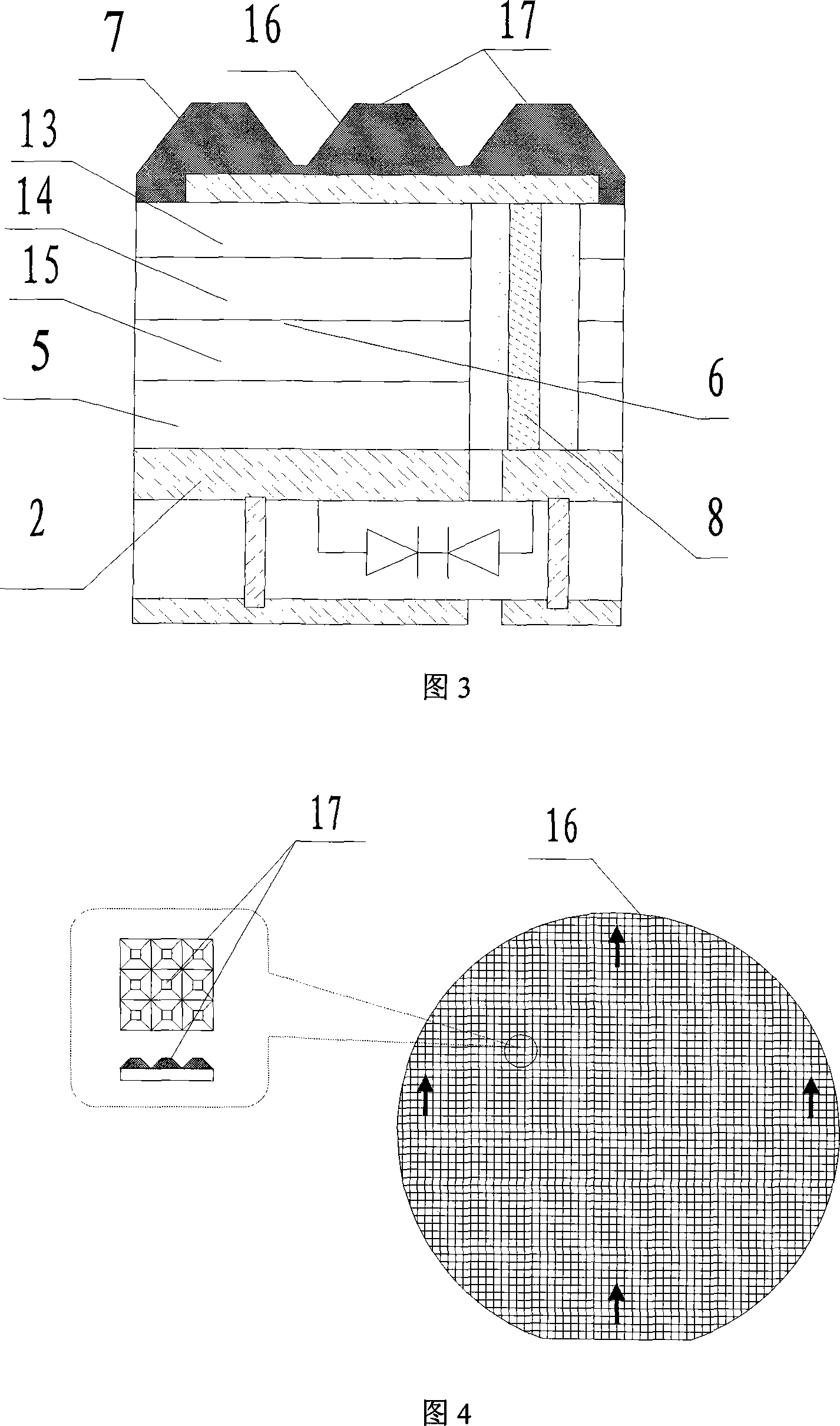

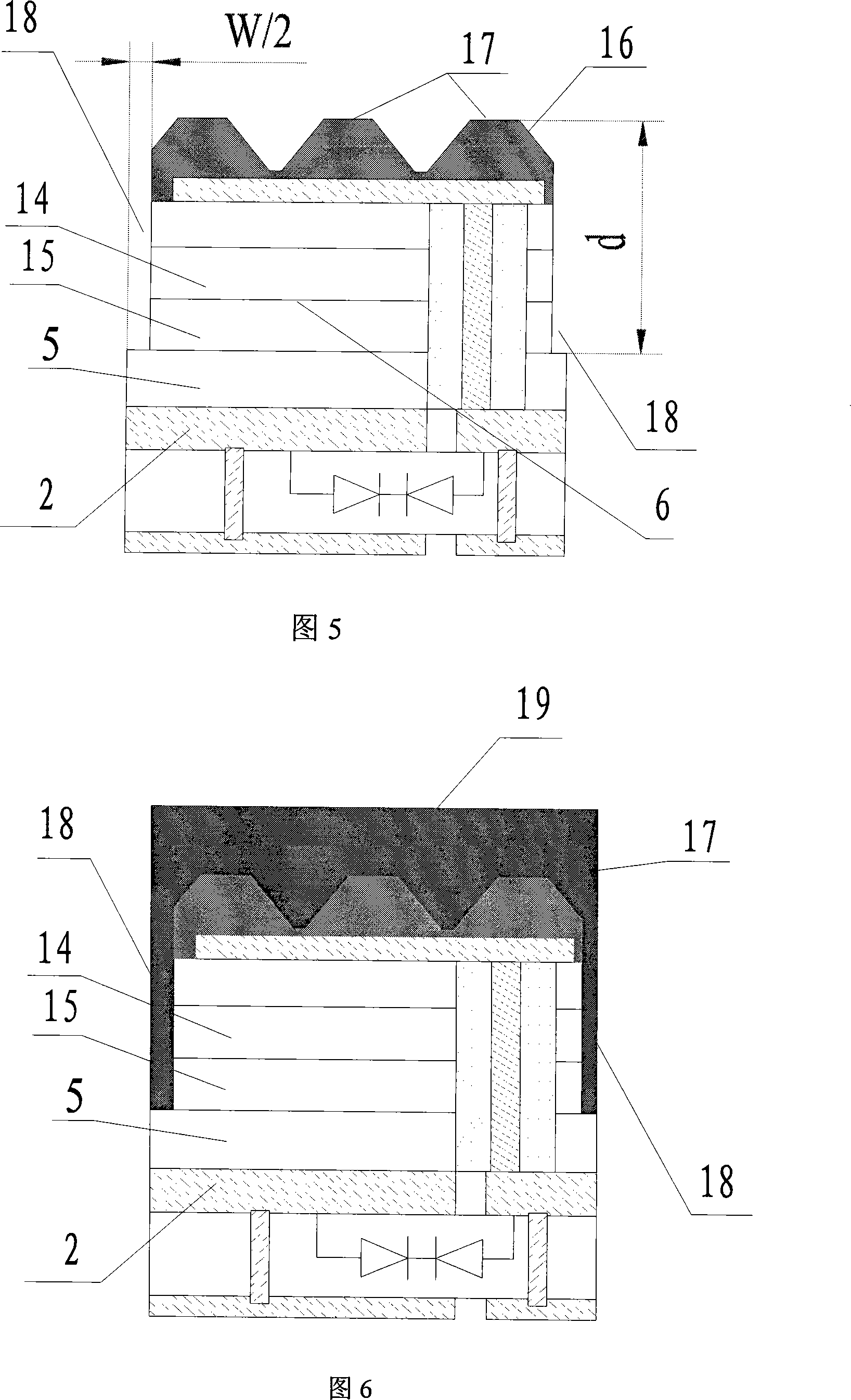

[0019] Firstly, a blue LED chip with a vertical through-hole structure is fabricated, as shown in FIG. 1 , an LED epitaxial layer 6 and a metallized silicon support substrate 2 with an antistatic diode are prepared. The LED epitaxial layer 6 includes GaN-based LED epitaxial wafers (polarized and non-polarized), GaP-based LED epitaxial wafers, ZnO-based LED epitaxial wafers, or epitaxial wafers of other semiconductor devices. For GaP-based LEDs, GaN-based LEDs, ZnO-based LEDs or other semiconductor devices. Different growth substrate materials are used, for example, GaAs growth substrate, GaP growth substrate, sapphire growth substrate, silicon carbide growth substrate, ZnO growth substrate, silicon growth substrate, compound GaN-based growth substrate, compound ZnO base growth substrate, etc. The epitaxial layer 6 of the LED is bonded to the metallized silicon support substrate 2 with antistatic diodes. Bonding methods include conductive glue, metal melting, metal diffusion,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com