Method for removing nitrate nitrogen from aquaculture water

A technology for aquaculture water and nitrate nitrogen, applied in anaerobic digestion treatment and other directions, can solve the problems of pH value drop, sulfate content increase, rise, etc., to achieve the effect of easy control of working conditions, reduction of side effects, and stable effluent quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

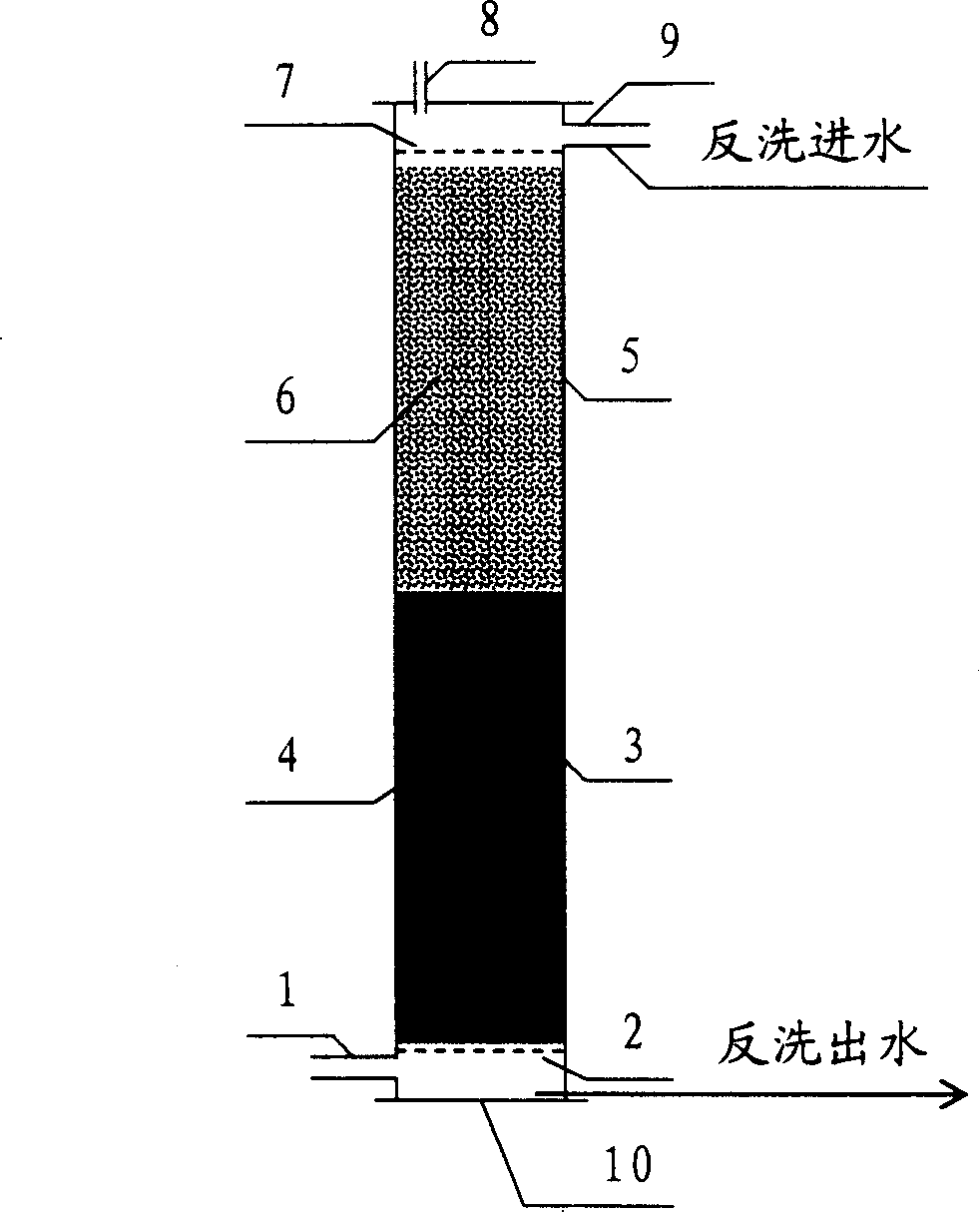

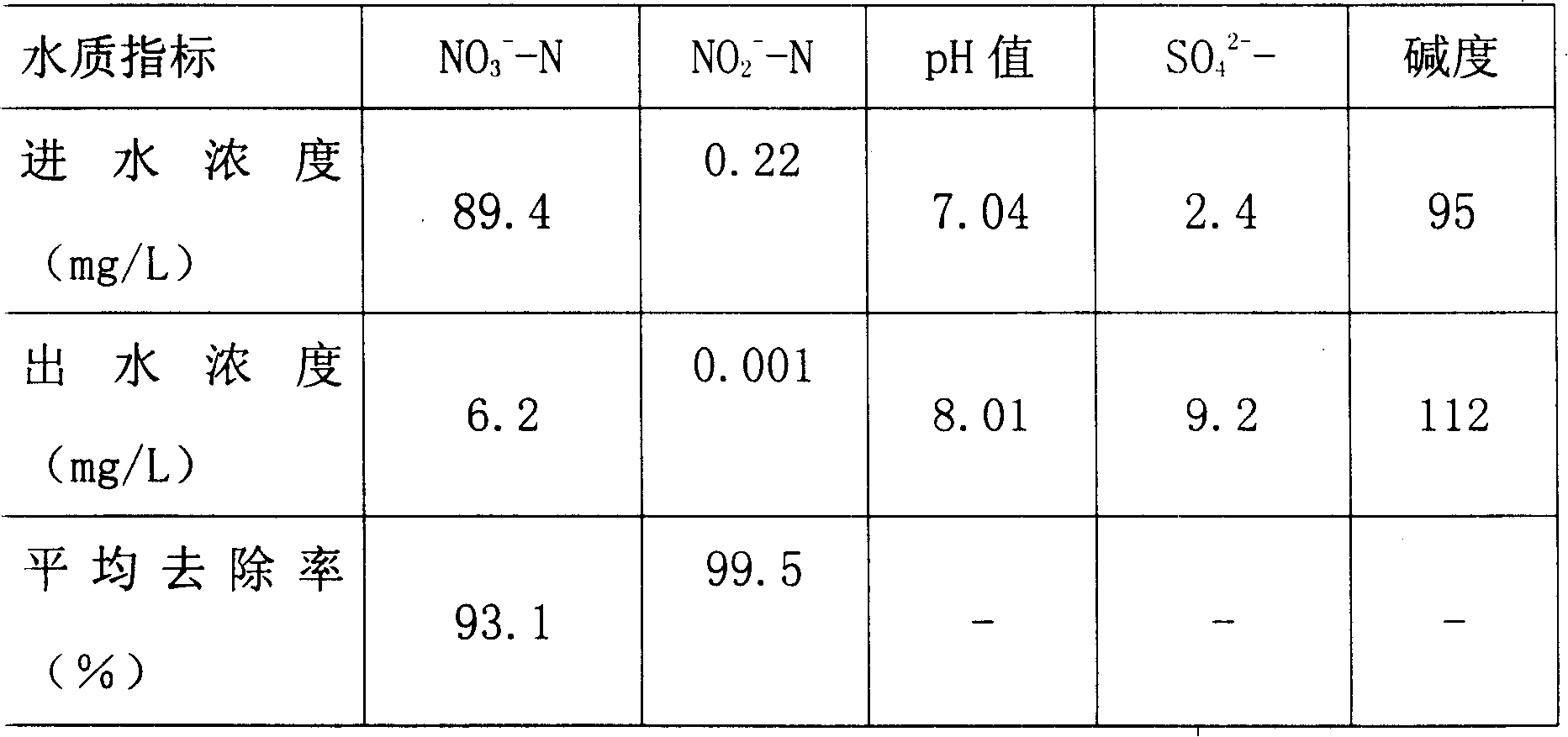

[0009] The purification mechanism of the present invention is that when the circulating aquaculture water flows through the sulfur / limestone filler layer, Thiobacillus denitrification uses elemental sulfur as the electron donor to perform autotrophic denitrification, reducing the nitrate nitrogen in the aquaculture water to nitrogen, and simultaneously producing a small amount of sulfuric acid Roots and other reaction products, limestone can further increase the alkalinity of aquaculture water while compensating for the alkalinity consumed by the autotrophic denitrification of Thiobacillus denitrificans; When the aquaculture water enters the BDPs carbon source filler and zeolite filler layer, the heterotrophic denitrification bacteria will remove the remaining nitrate nitrogen in the aquaculture water and produce gaseous nitrogen, and the sulfate reducing bacteria will reduce the sulfate radical to hydrogen sulfide; Removing sulfate is a process of increasing alkalinity. Adding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com