Composite oxide sosoloid based on cerium oxide and zirconia and method for preparing the same

A composite oxide and zirconia technology, which can be used in ceramic products, other household utensils, applications, etc., can solve the problems of long synthesis time and high preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Mix 33ml of cerous chloride solution (the concentration of cerium ion is 1mol / l), 11ml of solution of zirconyl dichloride (the concentration of zirconium ion is 1mol / l) and 15ml of H 2 o 2 Mix to obtain a mixed solution, add 8.1g of formic acid, stir and dissolve, add 80g of high molecular weight monomer methyl methacrylate and 0.8g of initiator azobisisobutyronitrile, stir continuously at room temperature to make the initiator dissolve completely, then add 4g of diisobutyronitrile Pan-80; stir to emulsify.

[0049] The emulsion was placed in a constant temperature water bath at 60°C, and reacted for 8 hours under constant stirring. Then the obtained polymer gel was dried in an oven at 120° C. for 12 hours, and the precursor obtained after drying was baked in a muffle furnace at 500° C. for 2 hours to obtain a fresh oxide.

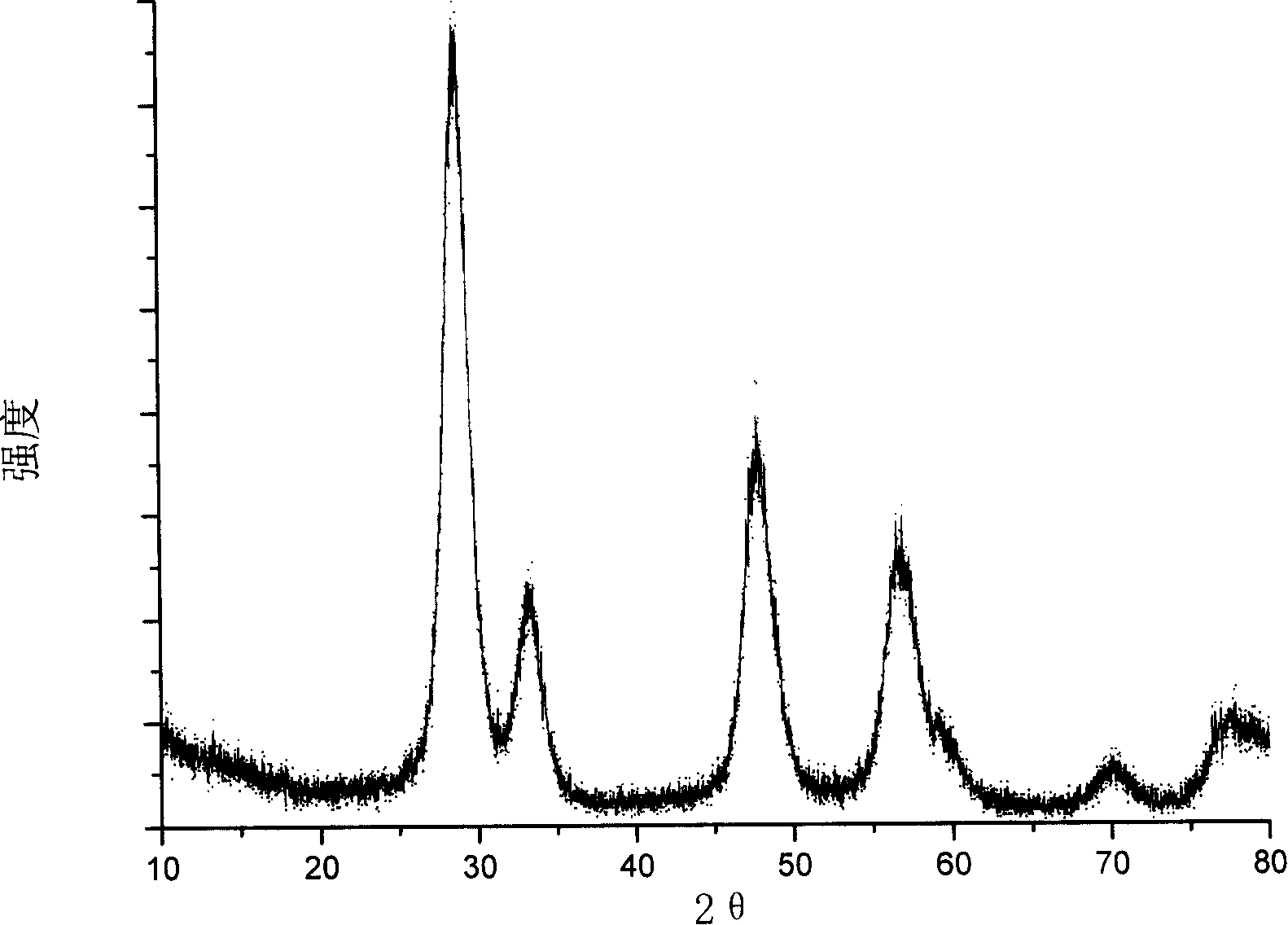

[0050] Take some fresh oxides and place them in a muffle furnace at 900°C for 6 hours to obtain aged oxides. The specific surface area after agin...

Embodiment 2

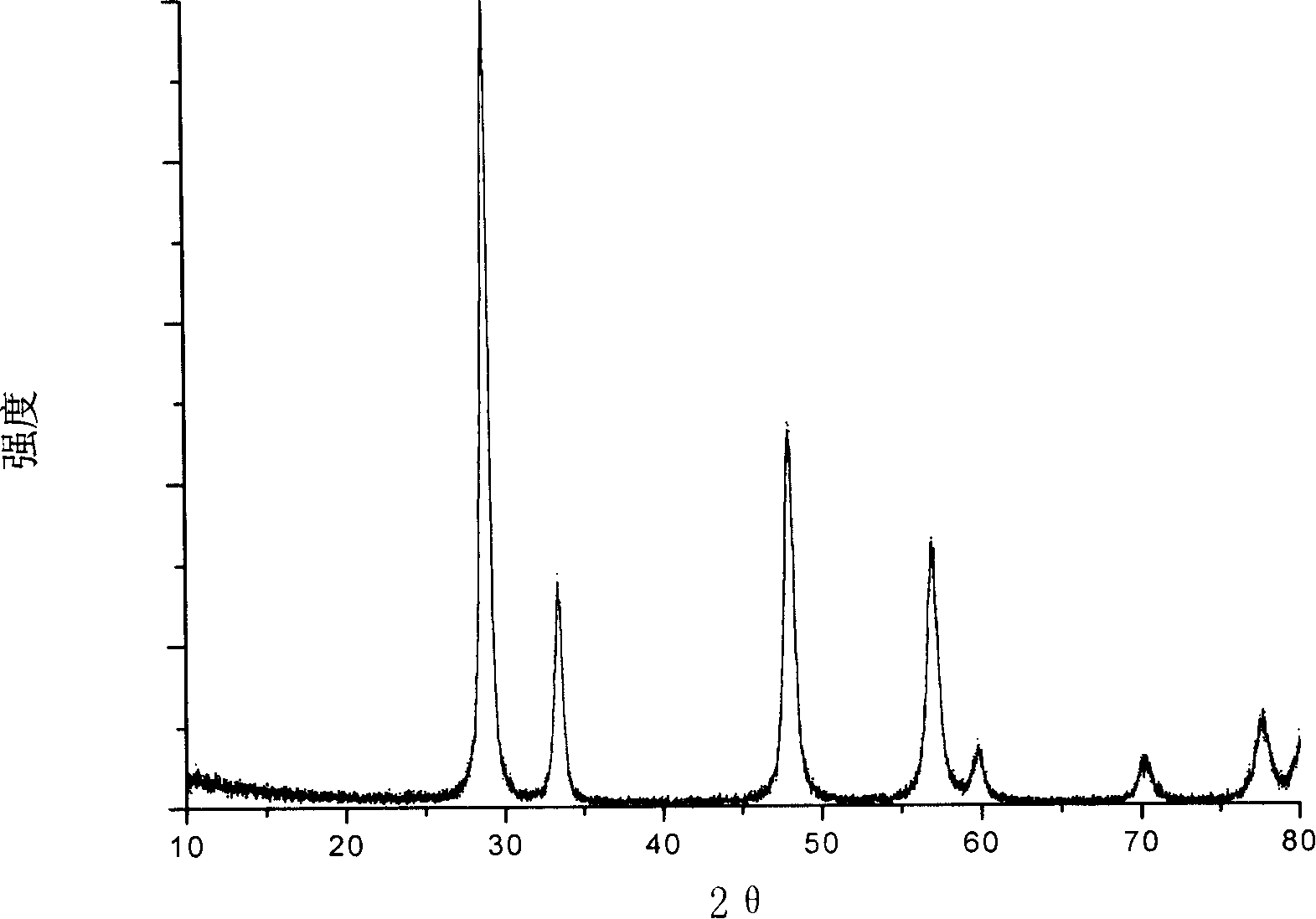

[0052] The same method as in Example 1, the difference is that H 2 o 2 The dosage was 30ml, 14g of citric acid was used instead of formic acid, the monomer type was changed to styrene, the surfactant system was changed to Span-85, the polymerization temperature was 80°C, and the polymerization reaction was carried out for 6 hours. The specific surface area of the resulting aged oxide is 38m 2 / g, the oxygen storage capacity is 7.71ml / g.

Embodiment 3

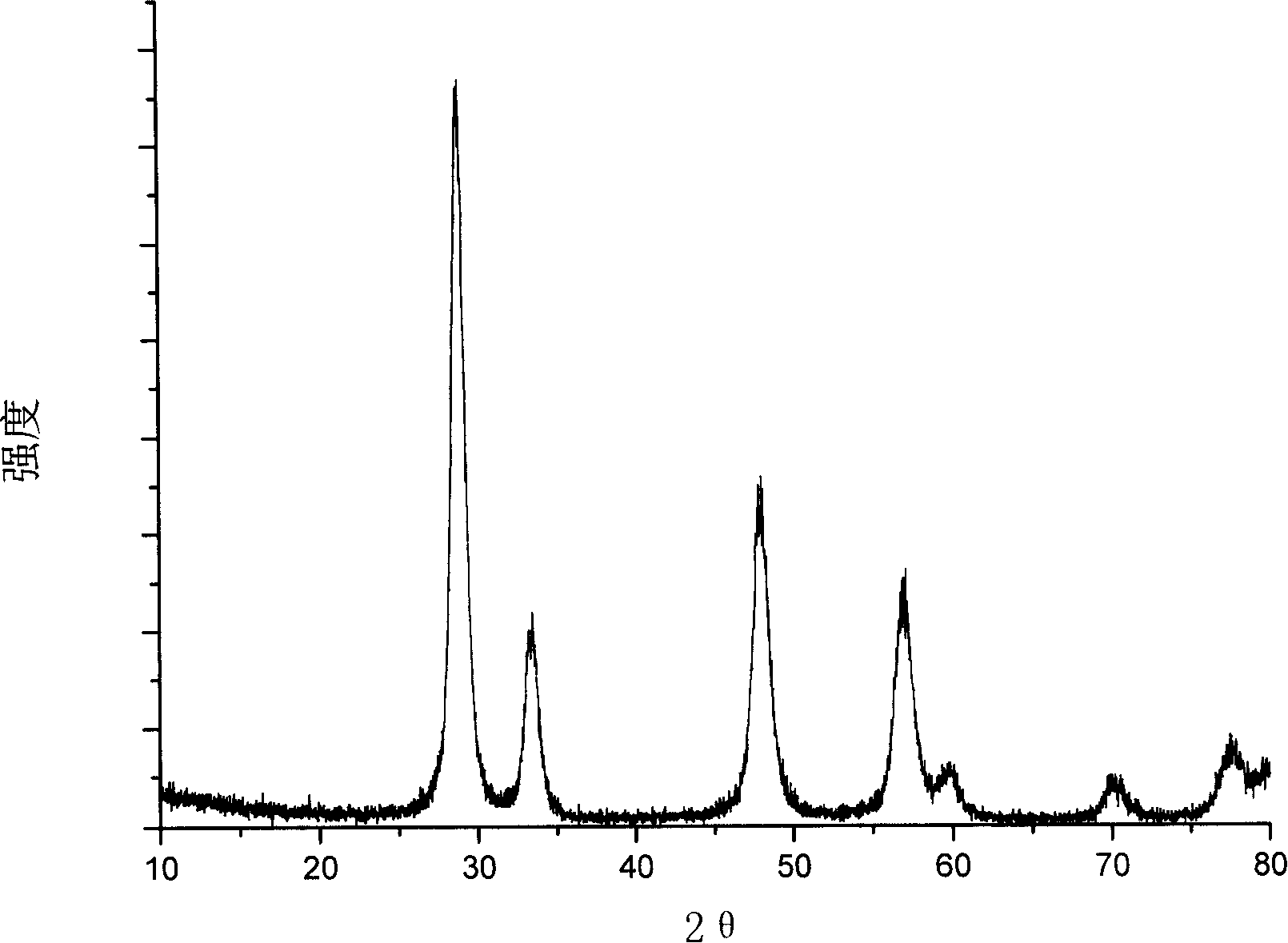

[0054] According to the same method as in Example 1, the difference is that H 2 o 2 The dosage is 22.5ml, 5.5g of acetic acid is used instead of formic acid, the initiator is dibenzoyl peroxide, the polymerization reaction temperature is changed to 80°C, and the polymerization reaction takes 12 hours. Take some fresh oxides and place them in a muffle furnace for 6 hours at 900°C to obtain aged oxides. The aging specific surface area is 34m 2 / g, the oxygen storage capacity is 7.54ml / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com