On-line leak detection method for lining of urea synthetic tower

A technology of a synthesis tower and a detection method, which is applied in the direction of detecting the appearance of a fluid at a leak point, a measuring device, an instrument, etc., can solve the problem that the use pressure of the carrier gas gas does not stipulate the safety operation rules of the urea synthesis tower, and the core instrumentation equipment is not mature enough. The problem of long response time of the leaking medium can achieve good application prospects, accurate and reliable detection results, and overcome the effect of hysteresis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

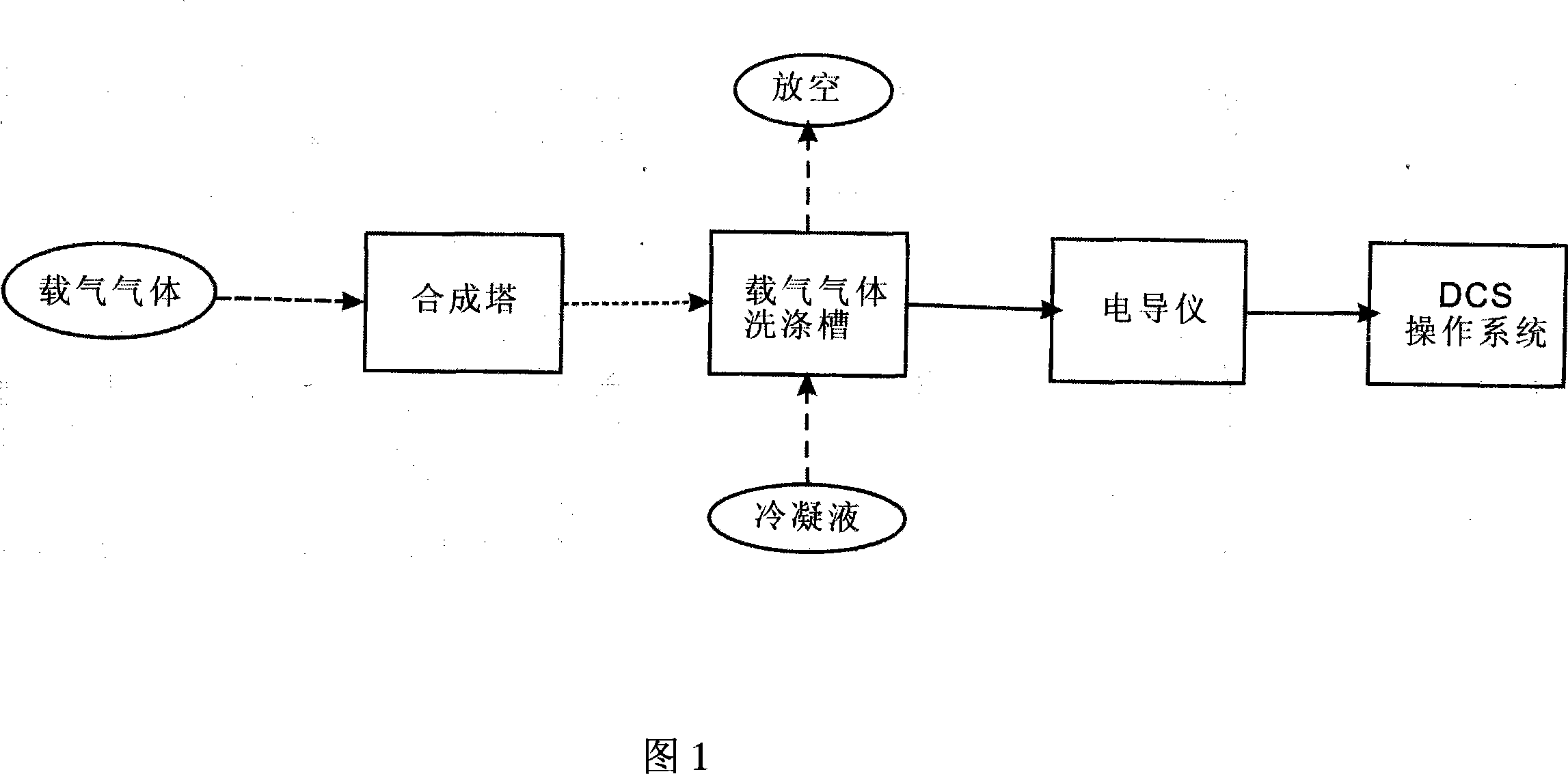

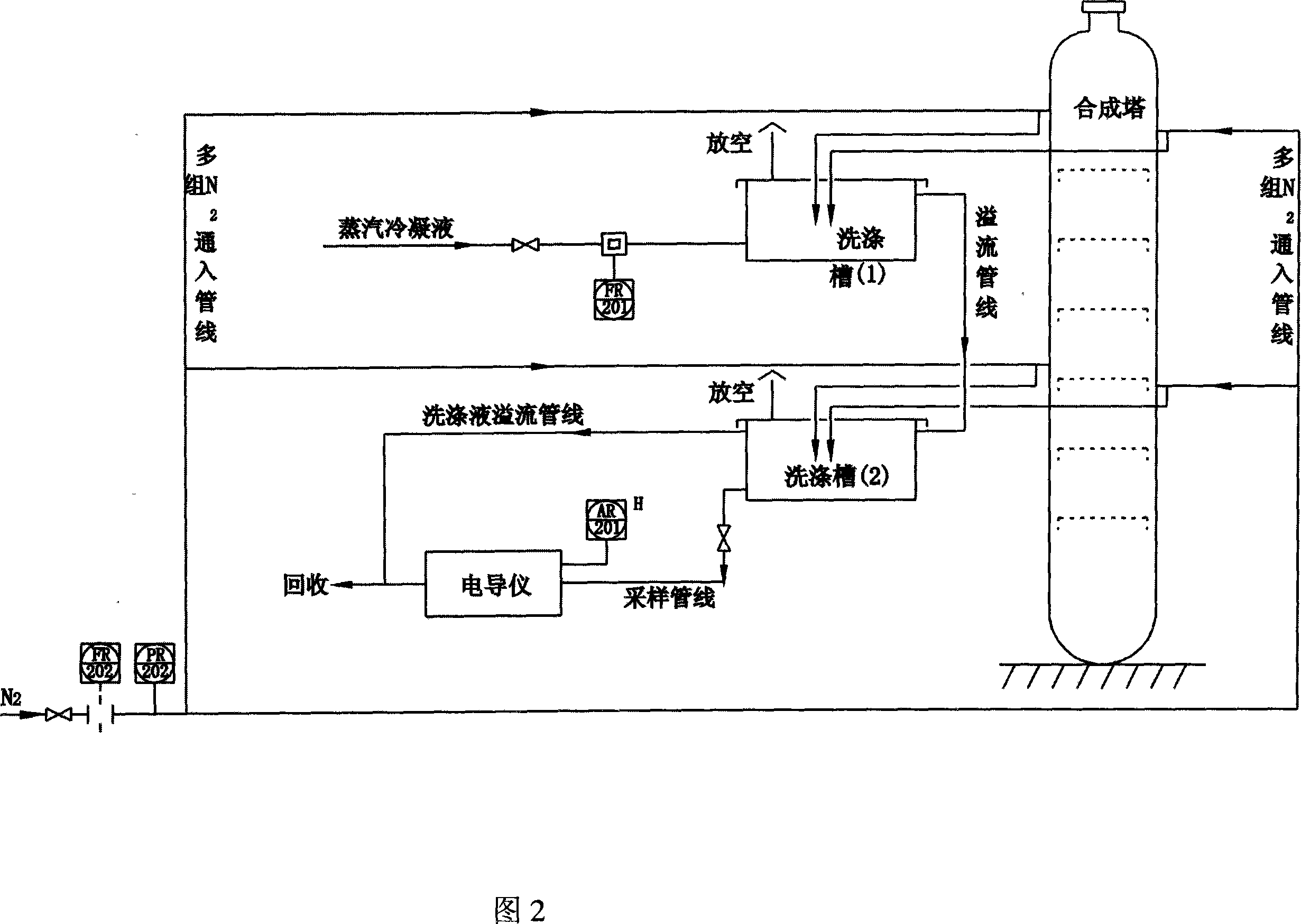

[0021] The invention proposes a method for online leak detection of the urea synthesis tower lining by continuously feeding carrier gas with constant pressure and using a conductivity meter to monitor the carrier gas washing liquid on-line. It is a low-investment online leak detection technology to improve the response speed and reliability of monitoring by using high-end conventional instruments.

[0022] The working process of the present invention is: the carrier gas with a certain pressure is continuously passed into the loose lining gap layer between the stainless steel lining and the shell and the annular leak detection channel from one side or both sides of the urea synthesis tower, and flows out of the leak detection hole The carrier gas is introduced into the washing tank and washed and absorbed by the continuously added steam condensate. The conductivity va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com