Device for automatically focusing and leveling

A leveling device and automatic focusing technology, which is applied in the direction of exposure devices, optics, instruments, etc. in the photoplate making process, can solve problems such as vibration difficulties, and achieve the effects of convenient optical path direction, reduced size, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following specific examples illustrate the implementation of the present invention, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

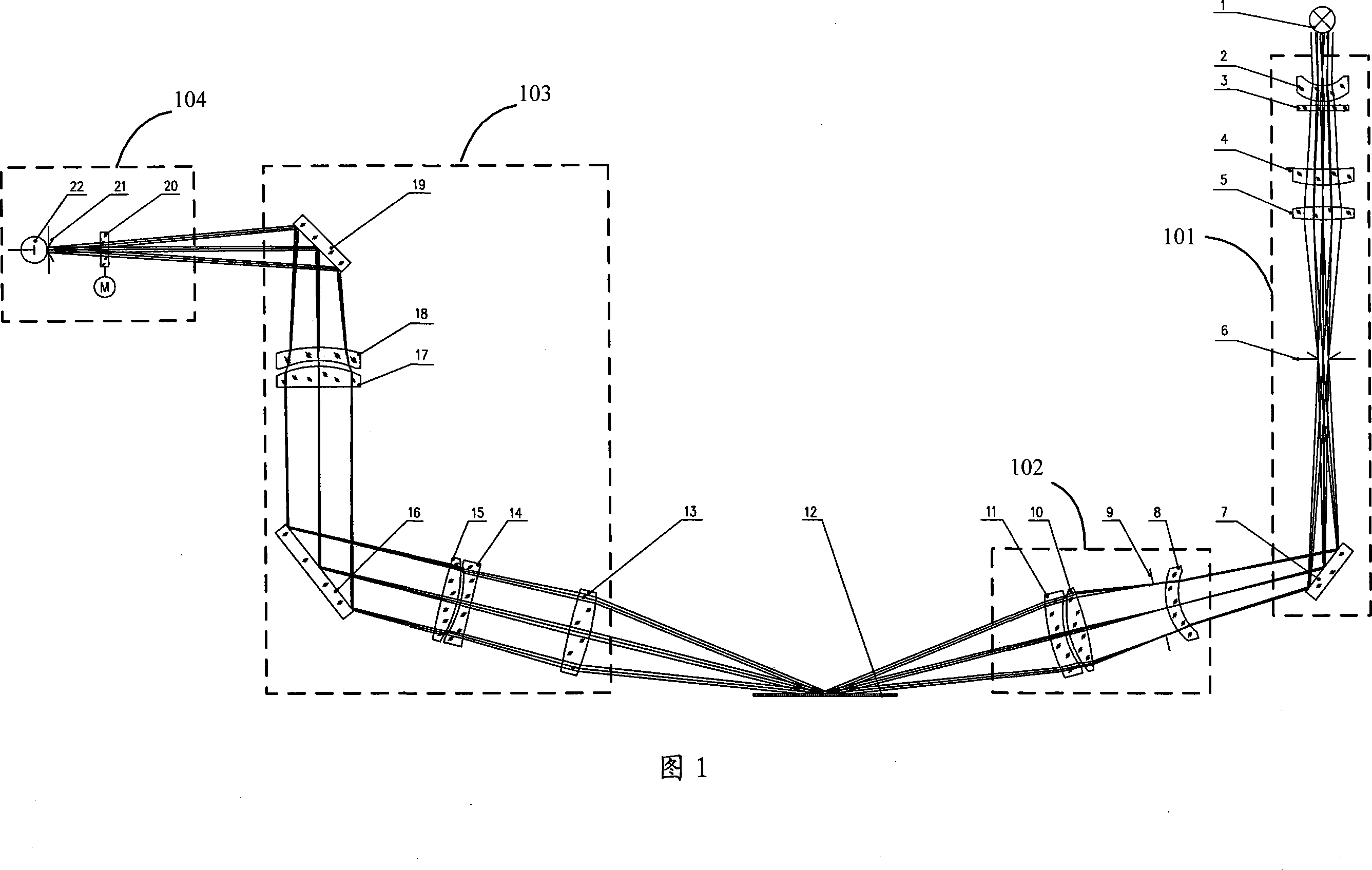

[0034] Hereinafter, each component of the automatic focusing and leveling device of the present invention will be described in detail with reference to FIG. 1.

[0035] As shown in Fig. 1, the light source 1 is the light emitted by the halogen tungsten lamp introduced by the optical fiber. The automatic focusing and leveling device of the present invention has an optical module and a control module (not shown in the figure) that are electrically connected to measure the height and tilt of the surface of the silicon wafer 12 relative to the focal plane of the projection objective, so that the entire exposure During the process, the silicon wafer is at the best focal plane position of the projection objective. The optical module includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com