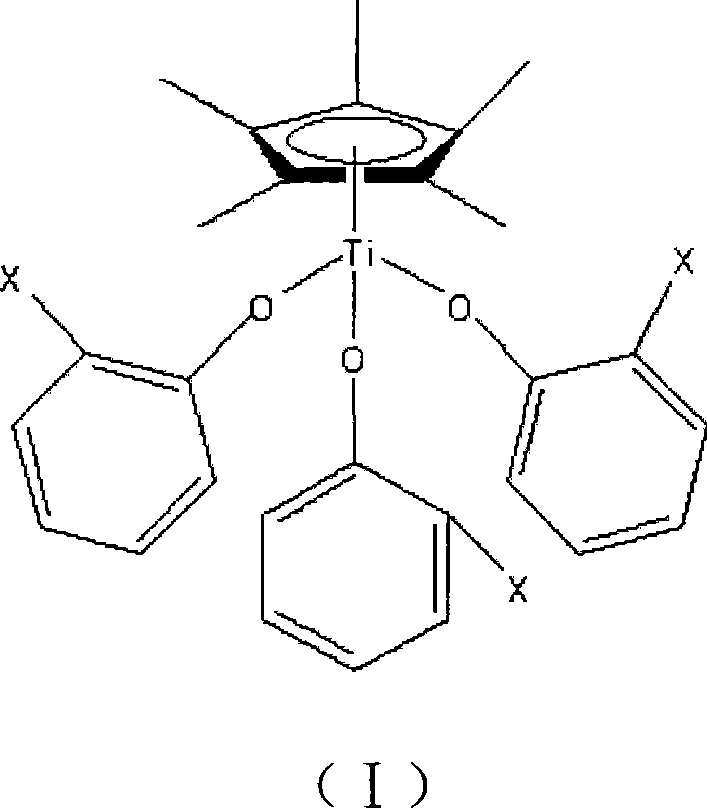

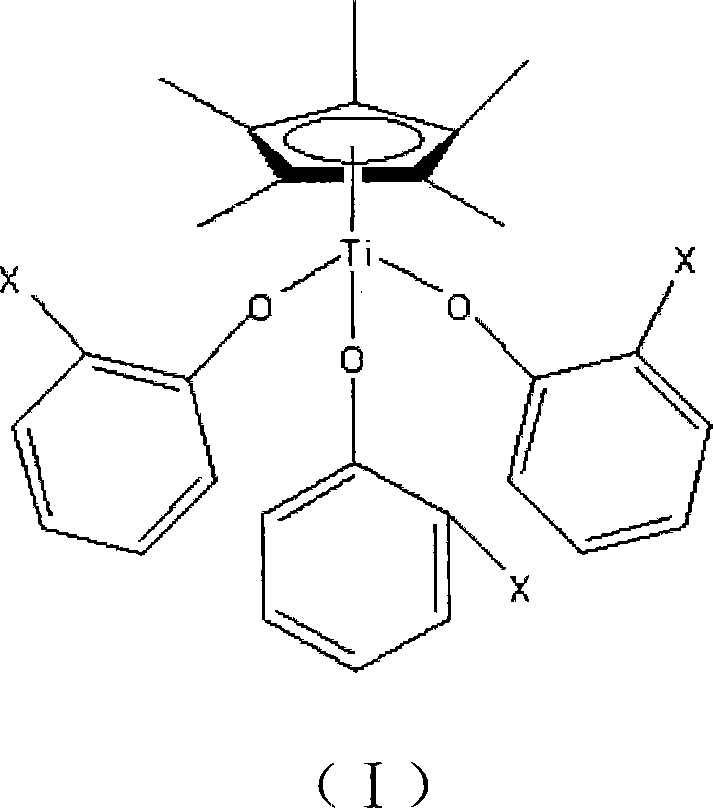

Titanocene compound catalyst and method for preparing syndiotactic polystyrene thereby

A compound and catalyst technology, applied in the field of syndiotactic polystyrene preparation, can solve the problem of low catalytic activity and achieve high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Example 1Cp * Ti(O-Ph-Cl) 3 Synthesis

[0013] 1. Synthesis of Pentamethylcyclopentadiene:

[0014] Heat 350mL of sec-butanol and 500mL of phosphoric acid (excessive) to 110°C for reaction, make the generated butadiene gas pass through the serpentine tube cooled by ice-water bath, enter 2000g of liquid bromine for reaction, and control the reaction temperature at -15°C with ice-salt bath Between -10°C, react until the liquid bromine changes from reddish brown to light yellow, and the product is subjected to liquid separation extraction and vacuum distillation to obtain 1570g of relatively pure 2,3-dibromobutane, with a yield of 58.1%, protected from light save. Put the mixed 119.3g potassium hydroxide, 22mL water and 205mL ethylene glycol into the constant pressure funnel, control the flow rate for 2 hours and add dropwise to 350g 2,3-dibromobutane heated to 100°C and mix with 140mL ethylene glycol Then reflux at 110°C for 2 hours to distill off, collect the crude p...

Embodiment 2

[0019] Example 2Cp * Ti(O-Ph-F) 3 Synthesis

[0020] O-fluorophenol replaces o-chlorophenol in Example 1, and other reaction conditions are the same. Elemental Analysis C 23 h 27 o 3 f 3 Ti: theoretical value: 65.05% for C, 5.421% for H; measured value: 64.48% for C, 5.430% for H.

Embodiment 3

[0021] Example 3Cp * Ti(O-Ph-CH 3 ) 3 Synthesis

[0022] Ortho-cresol replaces the ortho-chlorophenol in embodiment 1, and other reaction conditions are identical. Elemental Analysis C 29 h 45 o 3 Ti: theoretical value: 73.69% for C, 7.330% for H; measured value: 73.36% for C, 7.312% for H.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com