Olefin polymerization solid catalyst carrier and preparation thereof

A solid catalyst and olefin polymerization technology, applied in the field of magnesium chloride-containing carrier and preparation, can solve the problems of poor shape, low polymer bulk density, low catalyst loading titanium content, etc., achieve good fluidity and strength, and good particle shape , good catalytic activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

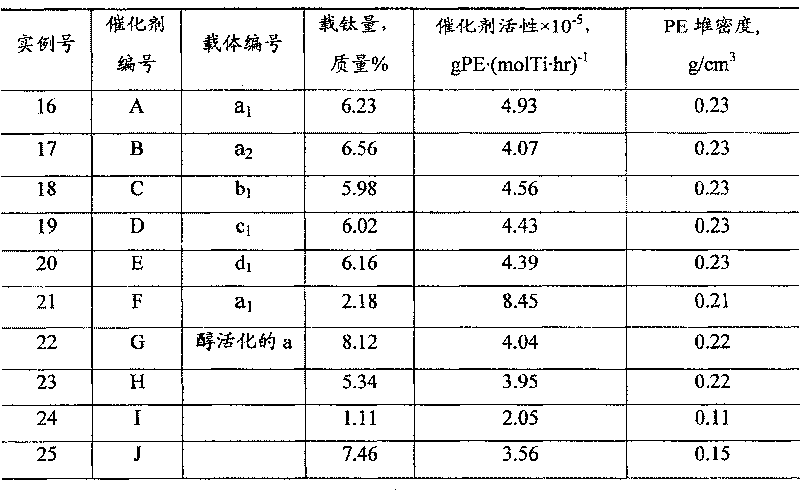

Examples

preparation example Construction

[0019] The preparation method of the carrier of the present invention comprises adding magnesium powder into a hydrocarbon solvent, adding an electron donor compound after stirring evenly, and then adding C with a molar ratio of 2.0 to 8.0:1 to the magnesium powder. 2 ~C 5 The halogenated alkane fully reacts, filters, collects solid matter washing and drying, and described electron donor compound is general formula Si(OR 3 ) 4 Siloxane and Ti(OR 2 ) 4 mixture.

[0020] In the above-mentioned carrier preparation process, the magnesium powder is mainly reacted with halogenated alkanes to generate active magnesium chloride, accompanied by the generation of alkylmagnesium chloride. The halogenated hydrocarbon is preferably C 2 ~C 5 monochlorinated alkanes such as chloropropane, chlorobutane, chloroisobutane, chlorotert-butane, chloroisopentane or chloropentane. The molar ratio of the halogenated hydrocarbon to the magnesium powder is preferably 2.5-5.0:1. The halogenated al...

example 1

[0032] Preparation of vectors described in the present invention.

[0033] Add 0.2mol magnesium powder, 150ml hexane, 6mmol n-butyl titanate, 36mmol tetraethyl orthosilicate and 0.02g iodine successively into a 250mL flask, heat to 75°C and stir for activation for 2 hours, then add dropwise 1mol of dry n-chloro Butane, obvious reaction can be observed, continue to react for 3 hours, filter, the gained solid is dried after washing with hexane, obtains active carrier a, and its composition formula is as follows:

[0034] (MgCl 2 )(BuMgCl) 0.58 Mg 0.08 [Ti(OC 4 h 9 ) 4 )] 0.07 [Si(OC 2 h 5 ) 4 ] 0.23

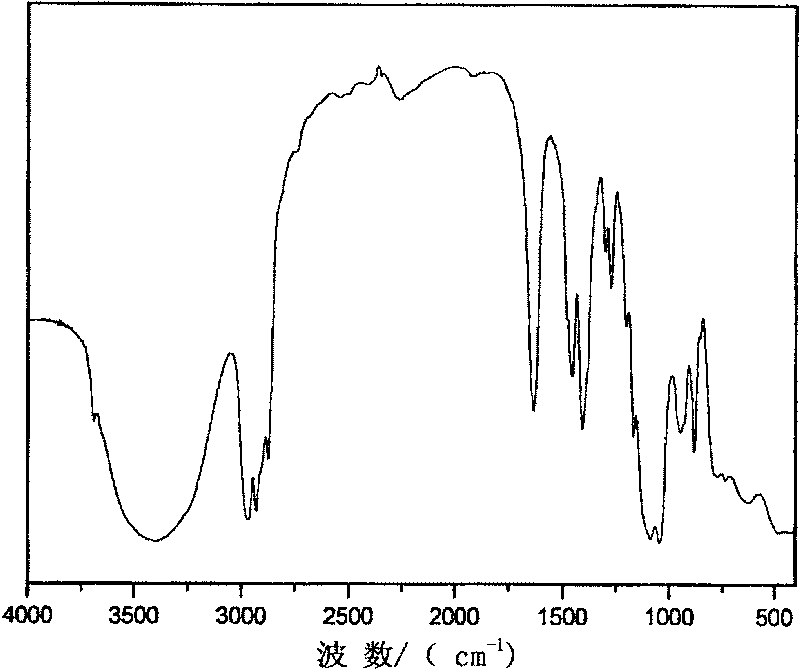

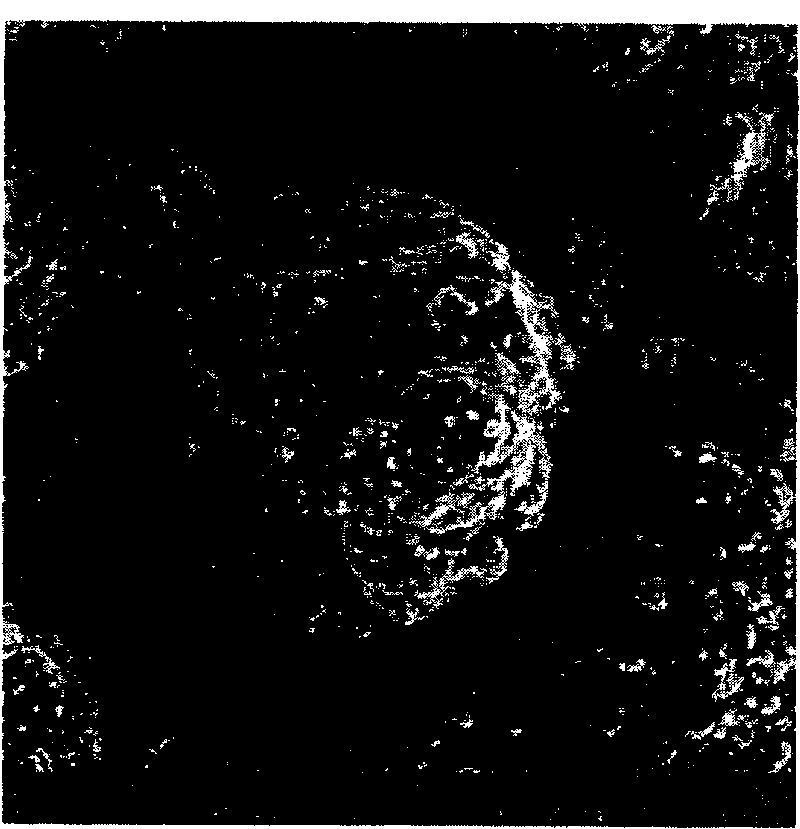

[0035] The infrared spectrogram of active carrier a is shown in figure 1 , a 400X magnified scanning electron microscope image is shown in figure 2 .

[0036] Depend on figure 1 It can be seen that the wave number is 1083.8cm -1 and 1047.2cm -1 There are two peaks with equal intensity at , which belong to Si-OC 2 h 5 Antisymmetric stretching vibration absorption...

example 2

[0041] The carrier was prepared according to the method of Example 1, except that the addition of n-butyl titanate was 3 mmol, and the addition of tetraethyl orthosilicate was 18 mmol. After drying, active carrier b was obtained, and its composition formula was as follows:

[0042] (MgCl 2 )(BuMgCl) 0.58 Mg 0.04 [Ti(OC 4 h 9 ) 4 ] 0.04 [Si(OC 2 h 5 ) 4 ] 0.12

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com