Preparation method of polyvinyl catalyst of loading semi-metallocene

A metallocene and catalyst technology, applied in the field of polyethylene catalyst preparation, can solve the problems of low polymer bulk density, poor shape, limited loading capacity, etc., and achieve good polymer particle shape, good fluidity and strength, good The effect of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

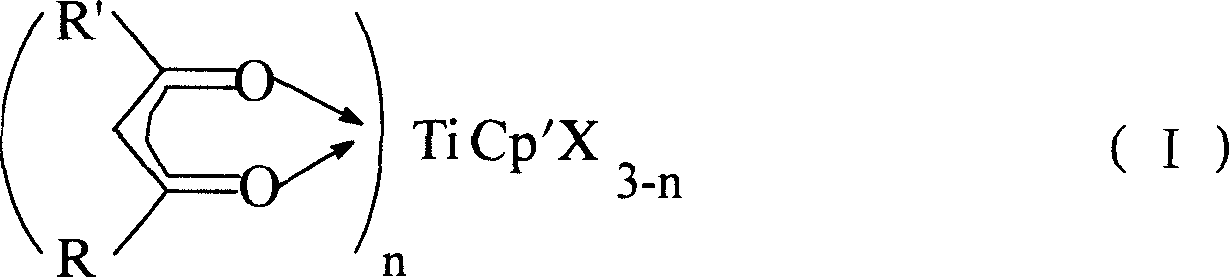

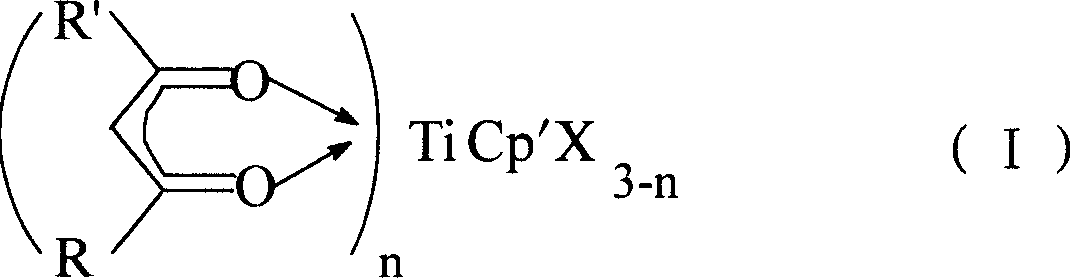

[0025] The preparation method of the semi-metallocene active component of the formula (I) is: in the presence of ether, make TiX 4 with the general formula R'-C(O)-CH 2 The β-diketone compound of -C(O)-R is reacted at the reflux temperature according to the molar ratio of 1:1-3, and the solvent is removed to obtain the β-diketone titanium compound. Then in an organic solvent, the alkali metal salt Cp'M of the cyclopentadiene skeleton compound and the β-diketone titanium compound are reacted in an equimolar ratio as in the presence of toluene, and the better method is to make the β-diketone titanium compound first Dissolve in toluene to prepare a solution, then add Cp'M, react at -15~25°C, remove the solvent, the obtained solid matter is preferably washed with ether, or the solid matter is recrystallized and purified as needed, and the solvent used for recrystallization For polar organic solvents, such as halogenated alkanes. M in said Cp'M is an alkali metal, preferably sodi...

example 1

[0030] The supported catalyst is prepared by the method of the invention.

[0031] (1) Preparation of cyclopentadiene-(dibenzoylmethane) titanium dichloride

[0032] TiCl with a concentration of 4.74% by mass 4 Ether solution, the ether solution of 56.06% by mass of dibenzoylmethane (produced by Shanghai Reagent Factory) is added in a closed container, and the TiCl 4 The molar ratio to dibenzoylmethane was 1:1, stirred and heated to reflux temperature, reacted for 1 hour, filtered, and the solid was washed 3 times with ether to obtain (dibenzoylmethane)titanium trichloride.

[0033] 5.5 milliliters of cyclopentadiene was dissolved in 25 milliliters of tetrahydrofuran, and 1.4 grams of sodium metal was added at -10°C to react for 2 hours. The solvent was removed under reduced pressure to obtain 4.67 grams of sodium cyclopentadiene.

[0034] Dissolve (dibenzoylmethane) titanium trichloride in toluene to form a solution of 94.35% by mass, then add a toluene solution with a conc...

example 2

[0040] Prepare supported catalyst B by the method for example 1, difference is (c) adds 40 milliliters and contains 3.7 grams (9.10 * 10 -3 mol) cyclopentadiene-(dibenzoylmethane)titanium dichloride dichloromethane solution, the obtained catalyst B had a titanium content of 6.23% by mass, a magnesium content of 9.12% by mass, and an aluminum content of 1.01% by mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com