Catalyst for preparing ultra-high-molecular-weight polyethylene and preparation method and application thereof

An ultra-high molecular weight and catalyst technology, applied in the production of bulk chemicals, etc., can solve the problems of coarse particle size and difficult to obtain ultra-high molecular weight polyethylene with small particle size, and achieve fine particle size, uniform particle distribution, high industrial The effect of applying value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

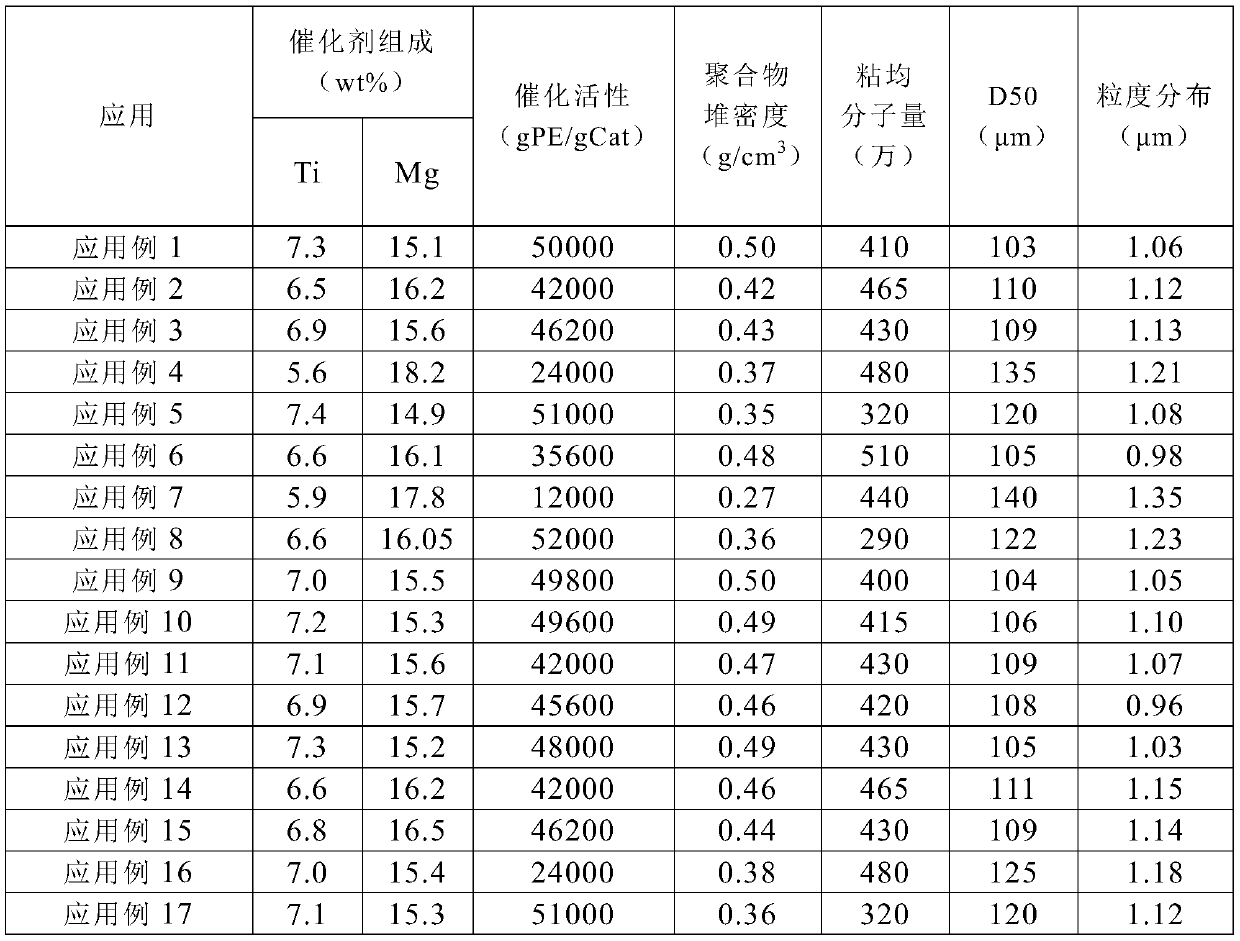

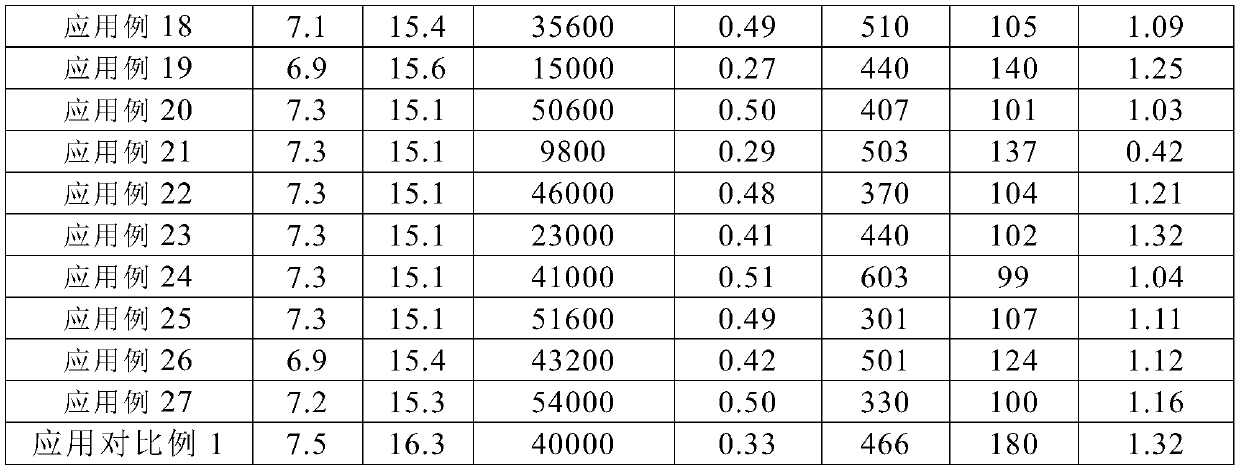

[0093] This embodiment provides a catalyst for preparing ultra-high molecular weight polyethylene, and the titanium content and magnesium content of the catalyst are shown in Table 1.

[0094] The preparation method of described catalyst comprises the steps:

[0095] (1) Put 4.76g (0.05mo1MgCl 2 , 30mL decane and 20mL isooctyl alcohol (0.125mol)) were heated to 130 ° C, after stirring for 60 min, a uniform solution was formed to obtain a magnesium alcohol mixture;

[0096] (2) Cool down the magnesium alcohol mixture to 75°C, add phthalic anhydride and 3-chloropropyltrimethoxysilane, wherein, anhydrous magnesium chloride, phthalic anhydride and 3-chloropropyltrimethoxysilane The mol ratio of oxysilane is 1:0.5:0.5, after stirring for 60min, the magnesium alcohol reaction solution is obtained, and the magnesium alcohol reaction solution is transferred to the constant pressure dropping funnel for subsequent use;

[0097] (3) Take another reaction bottle with mechanical stirring...

Embodiment 2

[0099] This embodiment provides a catalyst for preparing ultra-high molecular weight polyethylene, and the titanium content and magnesium content of the catalyst are shown in Table 1.

[0100] The preparation method of the catalyst is the same as in Example 1 except that the consumption of isooctyl alcohol in step (1) is adjusted to 25mL (that is, the molar ratio of anhydrous magnesium chloride to isooctyl alcohol is 1:3).

Embodiment 3

[0102] This embodiment provides a catalyst for preparing ultra-high molecular weight polyethylene, and the titanium content and magnesium content of the catalyst are shown in Table 1.

[0103] The preparation method of the catalyst is the same as in Example 1 except that the consumption of iso-octanol in step (1) is adjusted to 68mL (that is, the molar ratio of anhydrous magnesium chloride to iso-octanol is 1:8).

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com