Engineering machinery airborne teledata acquisition device and method

A construction machinery and remote data technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problem of inability to realize multi-channel fast real-time data collection and analysis, no battery and charging circuit, waste of vehicle battery energy, etc. problem, to achieve the effect of no omission of time tags, high compatibility and scalability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below in conjunction with accompanying drawing and the specific embodiment that is applied to the remote monitoring data acquisition of a QUY250A hydraulic crawler crane produced by Fudu Company, the present invention is described in detail: the present embodiment is carried out under the premise of the technical solution of the present invention, and given The detailed implementation and process are shown, but the protection scope of the present invention is not limited to the following examples.

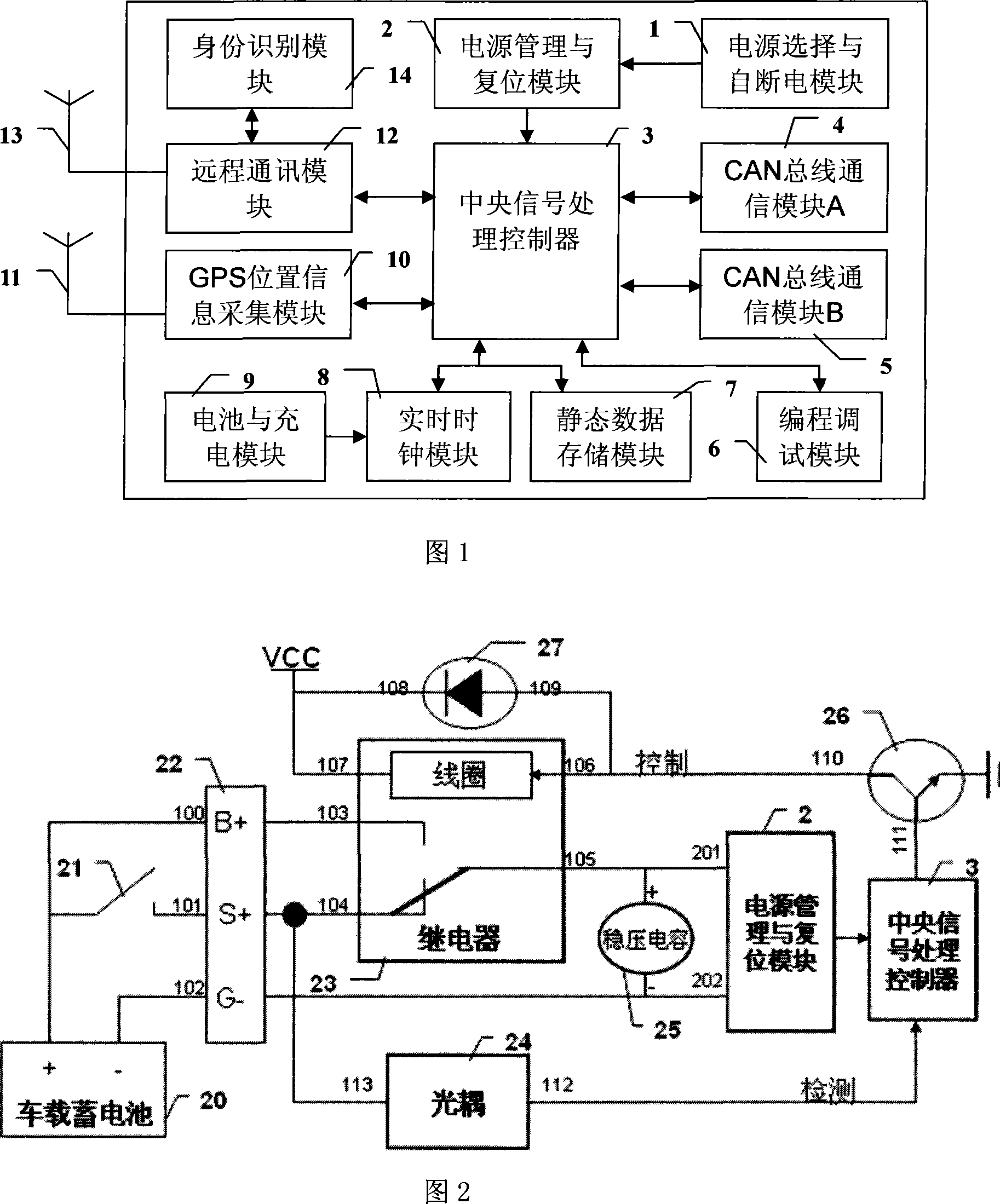

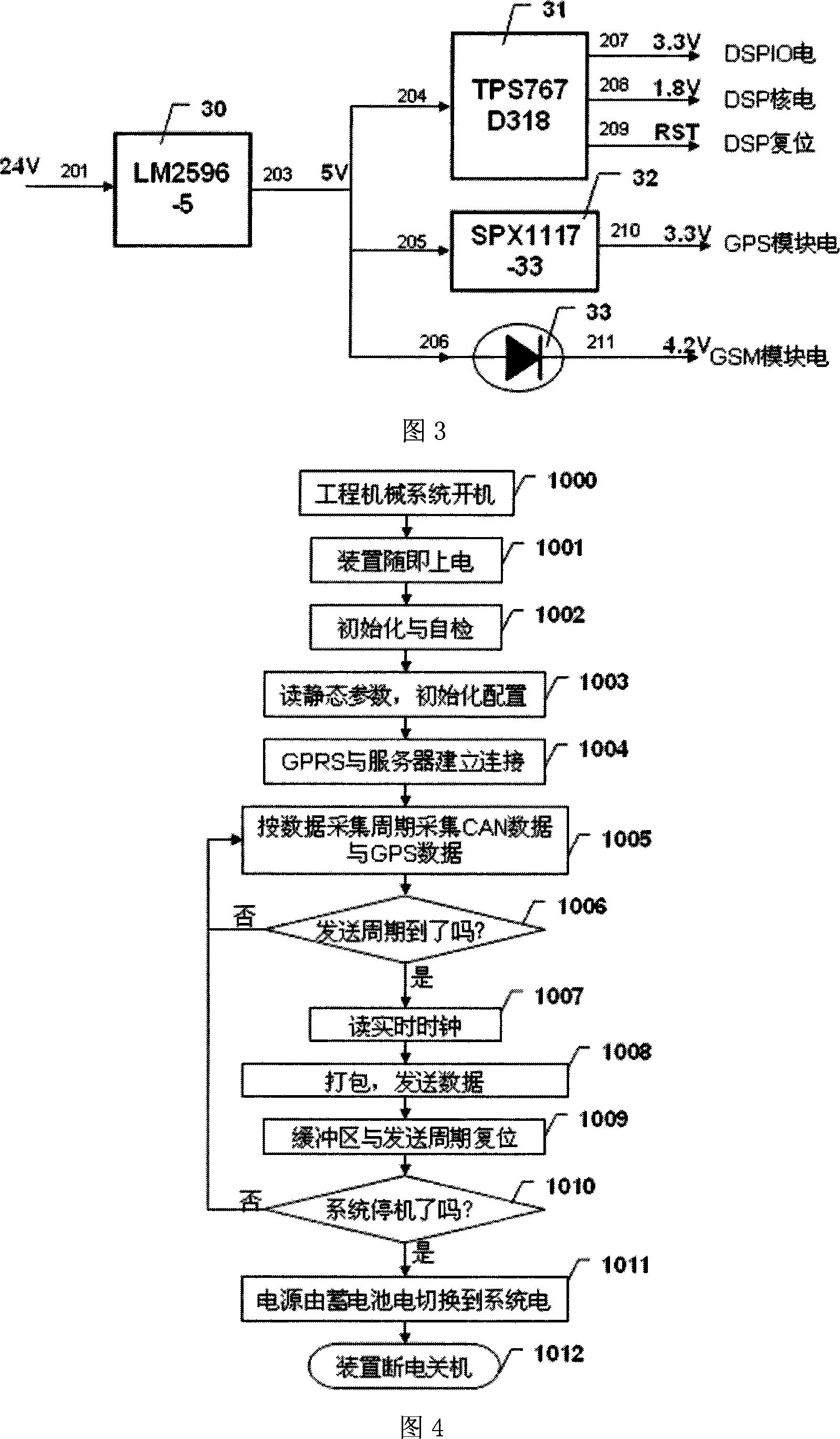

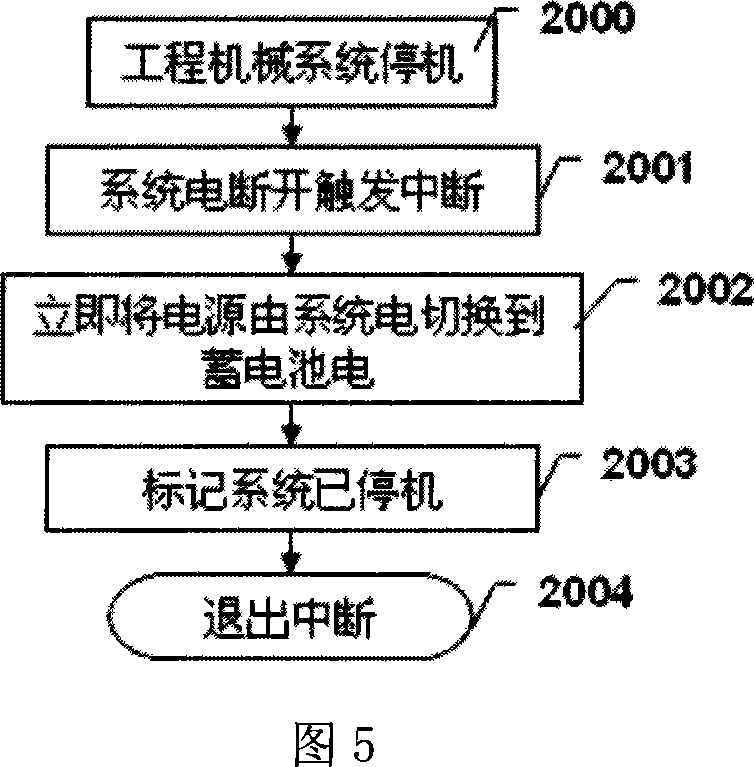

[0051] As shown in Fig. 1, a kind of engineering machinery airborne remote data acquisition device described in this embodiment includes: power supply selection and self-power-off module 1, power management and reset module 2, central signal processing controller 3, CAN bus Communication module 4, CAN bus communication module 5, programming and debugging module 6, static data storage module 7, real-time clock module 8, battery and charging module 9, GPS position information a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com