Process and composition for coating propagation material

A technology of coating materials and plant propagation materials, which is applied in the field of coating compositions for plant propagation materials, can solve problems such as unsatisfactory effects, and achieve the effects of reducing flying dust/flaking, reducing phytotoxicity, and reducing loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

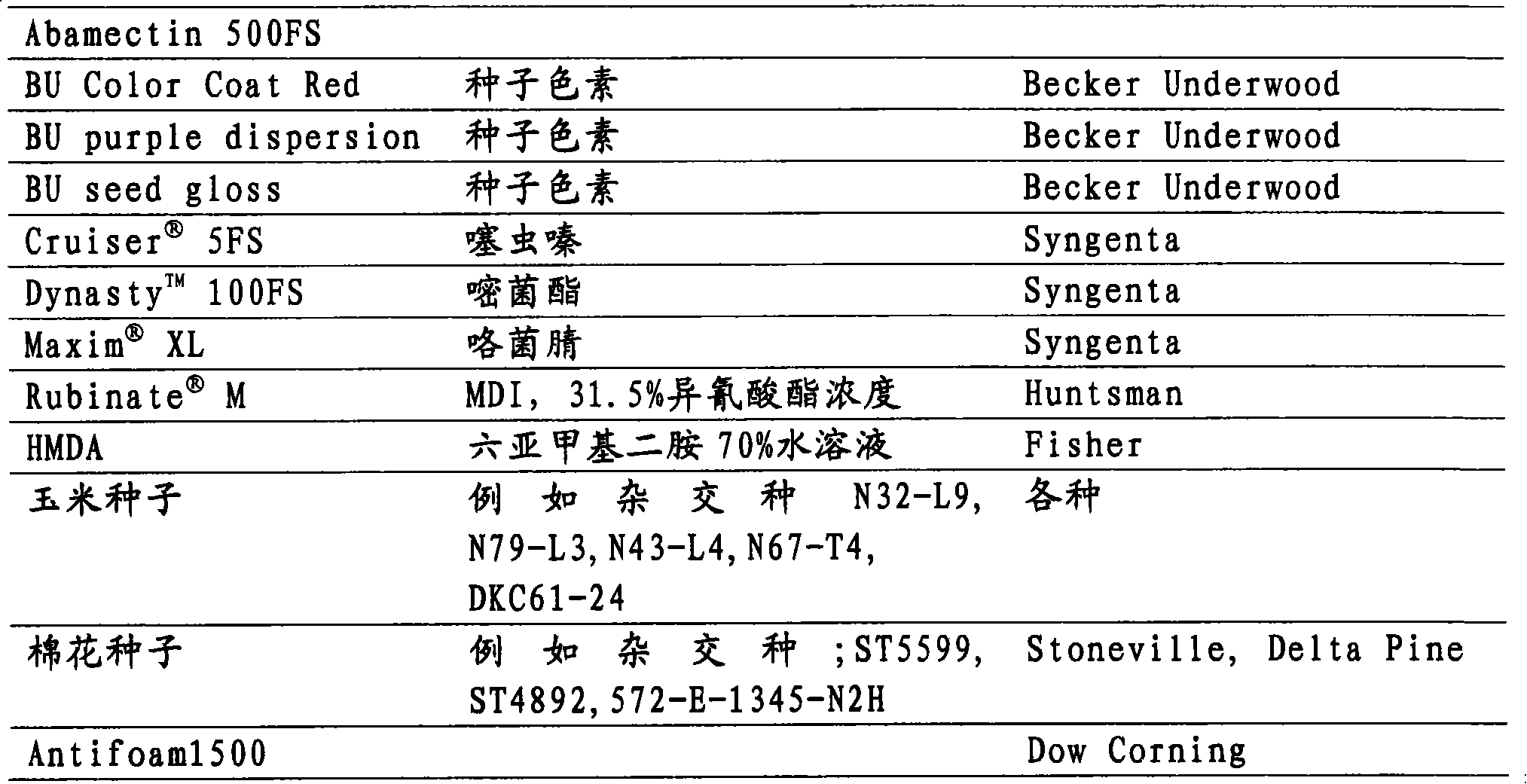

[0094] In order to enable those skilled in the art to better implement the present invention, the following examples are given by way of illustration rather than limitation. Registered trademarks and other designations denote the products listed below. The provider is known or easy to find.

[0095]

Embodiment A-D

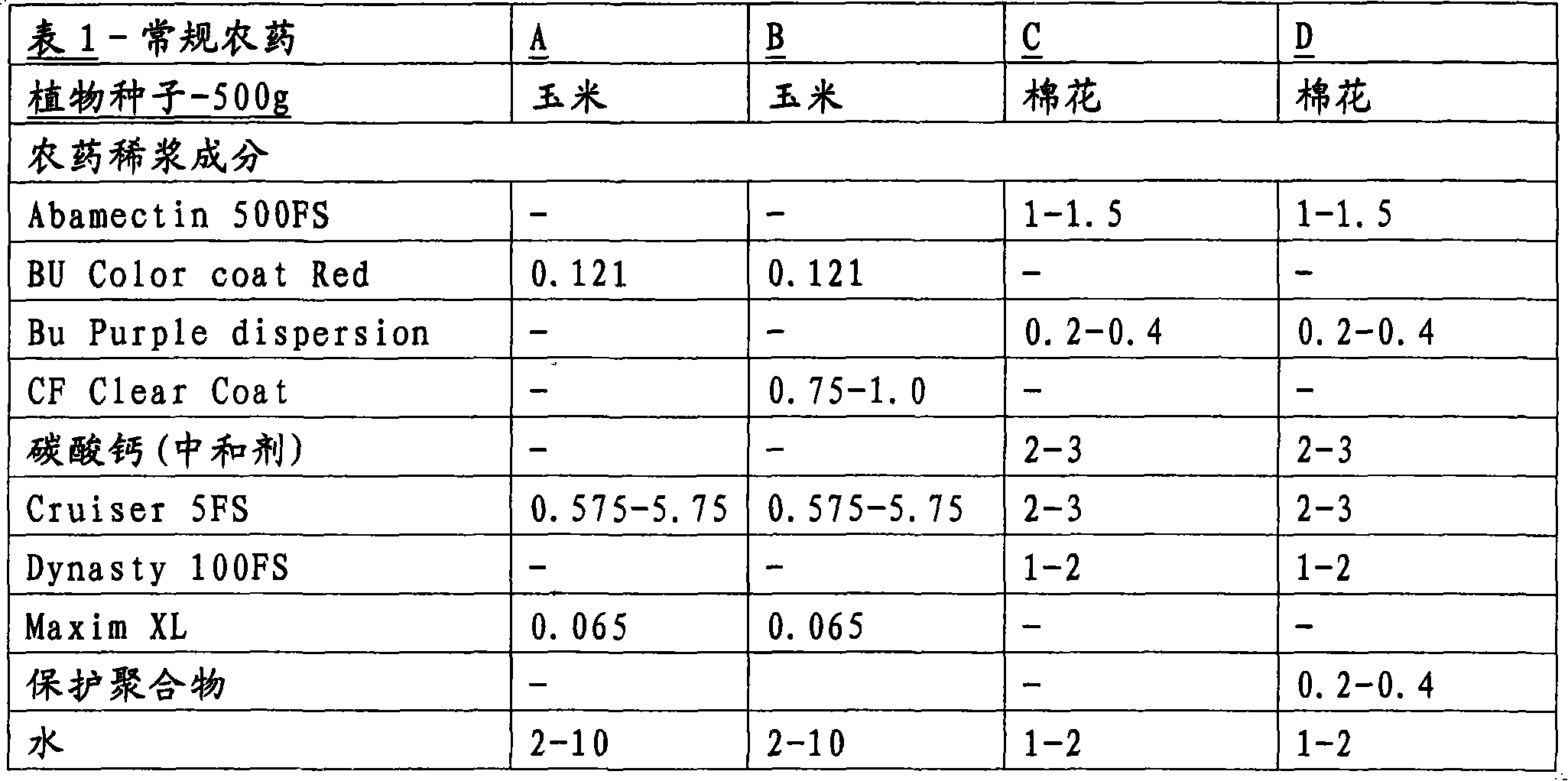

[0096] Examples A-D - Conventional pesticide seed treatment

[0097] Examples A-D illustrate corn and cotton seed dressing with conventional pesticide seed treatments. 500g of seeds were placed in the treatment cartridge of the Hege 11 seed processor. An aqueous pesticide slurry is then prepared by mixing the pesticide, colorant, polymer, neutralizer (if any), and water until a homogeneous phase is formed. The Hege engine was turned on and the resulting slurry was coated onto the rotating disc of the seed processor via a syringe into a tumbling bed. When the seeds are almost dry (takes up to 1 minute) stop stirring. Table 1 details the seed treatment compositions used. The numbers given in this table represent the weight of ingredients in g / 500g of seeds. All machine settings were made according to the manufacturer's recommendations and were within the routine ranges understood by those skilled in the seed coating art.

[0098]

Embodiment 1

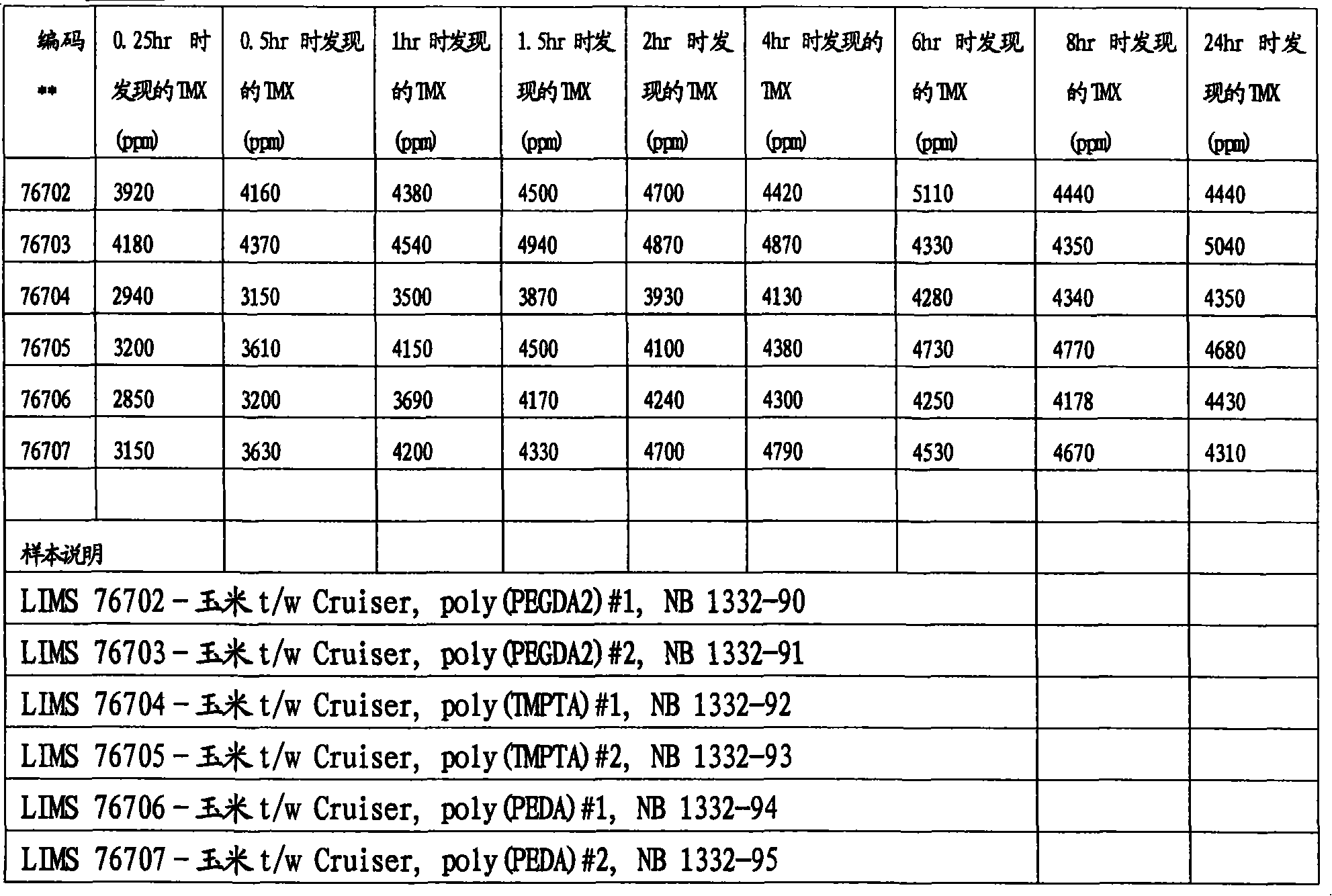

[0099] Example 1 - Michael addition

[0100] Example 1 illustrates the preparation of polymeric protective coatings on pesticide-treated corn and cotton seeds. Corn and cotton seeds were treated with pesticides according to the methods of Examples A and C, respectively. 500 g of pesticide treated corn or cotton seeds, as appropriate, were placed in the treatment cartridge of the Hege 11 Liquid Seed Treater as described above. Then, 3.00 g of polyethylene glycol diacrylate (Mn=263), a polypolyethylenically unsaturated monomer obtained from Sigma-Aldrich, Milwaukee, WI, was injected onto the rotating disk of the seed treater. After the material has substantially coated the rotating seeds, the rotation is briefly stopped to allow the rotating disk to be wiped clean to prevent reactions on the disk. Subsequently, the diamine, 3.79 g of a 35 wt % aqueous solution of hexamethylenediamine, was injected onto the rotating disk of the seed processor. The reaction occurs within second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com