Carboxylic acid polyalcohol water reducing agent capable of controlling concrete slump loss

A technology of slump loss and carboxylic acid polymer, which is applied in the field of water reducing agent to control concrete slump loss, can solve the problems of fresh concrete slump loss, reducing the dispersion effect of water reducing agent, and high process reaction temperature , to achieve the effect of improving slump loss, controlling slump loss and delaying physical coagulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

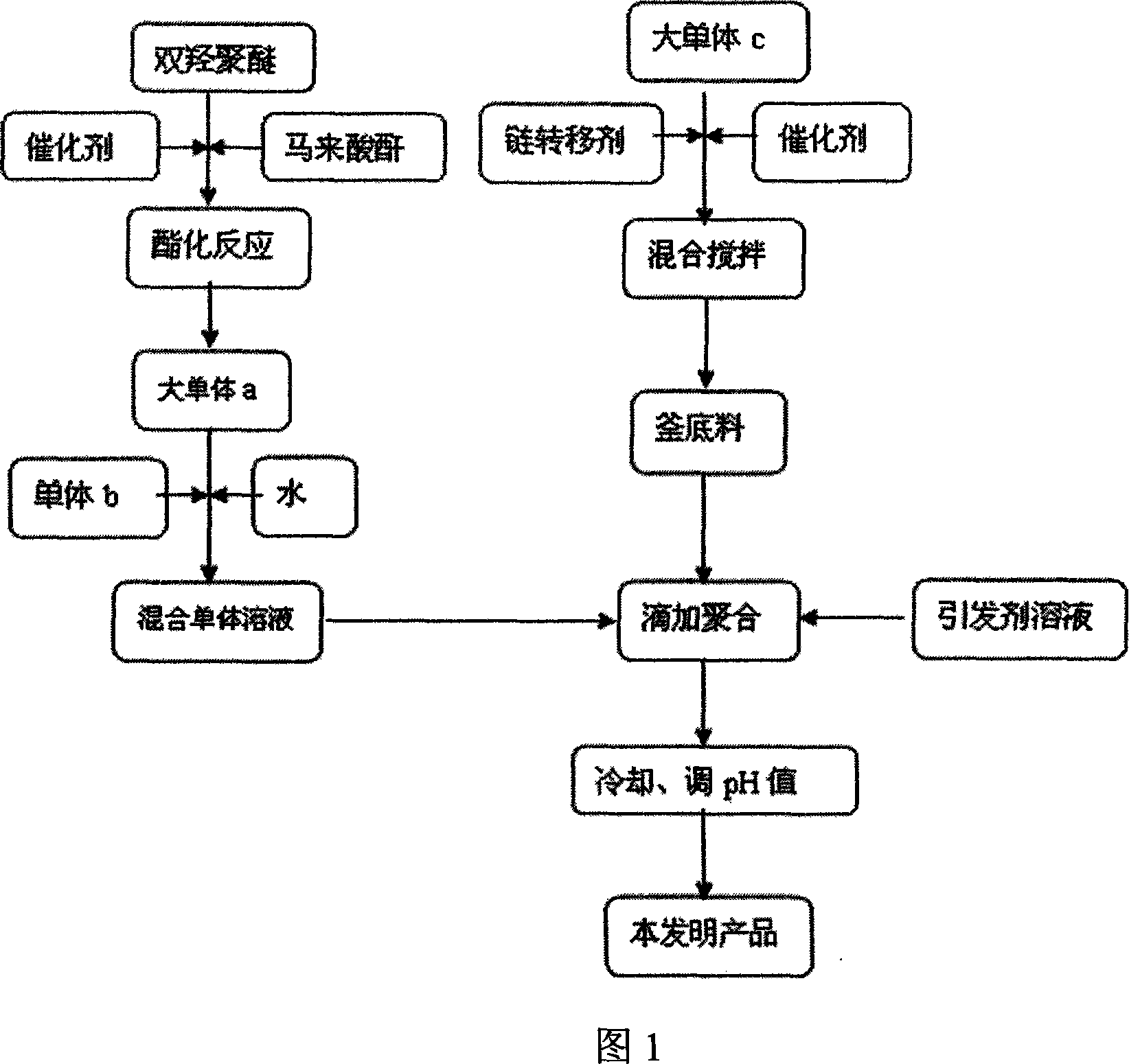

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 Preparation of water reducer of the present invention

[0037] 1) Esterification reaction

[0038] Melt 100g of polyethylene glycol 1000 at 80-90°C, put it into a four-necked flask, add 49g of maleic anhydride, stir and dissolve evenly, add 4g of catalyst p-toluenesulfonic acid and stir to dissolve, then add 0.20g of catalyst concentrated Sulfuric acid, after stirring evenly, add the solvent cyclohexane (the amount of solvent is based on normal reflux), the temperature of the feed liquid is raised to 110°C, the reaction is carried out under reflux and the water is separated, and the water output in the water separator is measured every 1 hour , to stop the reaction when the water output is close to the theoretical value. In the reaction process, in order to maintain the normal progress of the reflux, an appropriate amount of cyclohexane solvent can be supplemented. After the reaction, cyclohexane was distilled off under reduced pressure to obtain formula ...

Embodiment 2

[0046] (1) Esterification reaction

[0047] The steps are the same as in Example 1, except that the reflux reaction temperature is 120°C.

[0048] (2) Polymerization reaction

[0049] The steps are the same as in Example 1, except that the amount of monomer c to be fed is measured according to the molar ratio of a to c of 1:2.

Embodiment 3

[0051] (1) Esterification reaction

[0052] The steps are the same as in Example 1, except that the reflux reaction temperature is 135°C.

[0053] (2) Polymerization reaction

[0054] The steps are the same as in Example 1, except that the feed amount of monomer c is measured according to the molar ratio of a and c being 2:1.

[0055] The water reducing agents prepared in Example 1, Example 2 and Example 3 were added to the concrete according to the solid content of 0.2% (that is, the weight percentage of the cement), and the cement in the concrete was all made of Onoda cement (P.II 52.5) . The initial slump of the concrete is controlled at 18-20cm. After 2 hours, the slump retention rate and related index performance are tested. The measured data are shown in comparison table 2.

[0056] Table 2 The effect of different feed ratios of a and c on the performance of concrete

[0057] Test items

[0058] From the test results of the three comparative examples, it c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com