Sludge desiccation burning integral treatment method and device

A sludge drying and incineration device technology, which is applied in the direction of sludge treatment, combustion methods, and drying solid materials through temperature control, can solve problems such as low reliability, low thermal efficiency, and large heat loss, and improve operational reliability. , Reduce investment costs, reduce the effect of operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

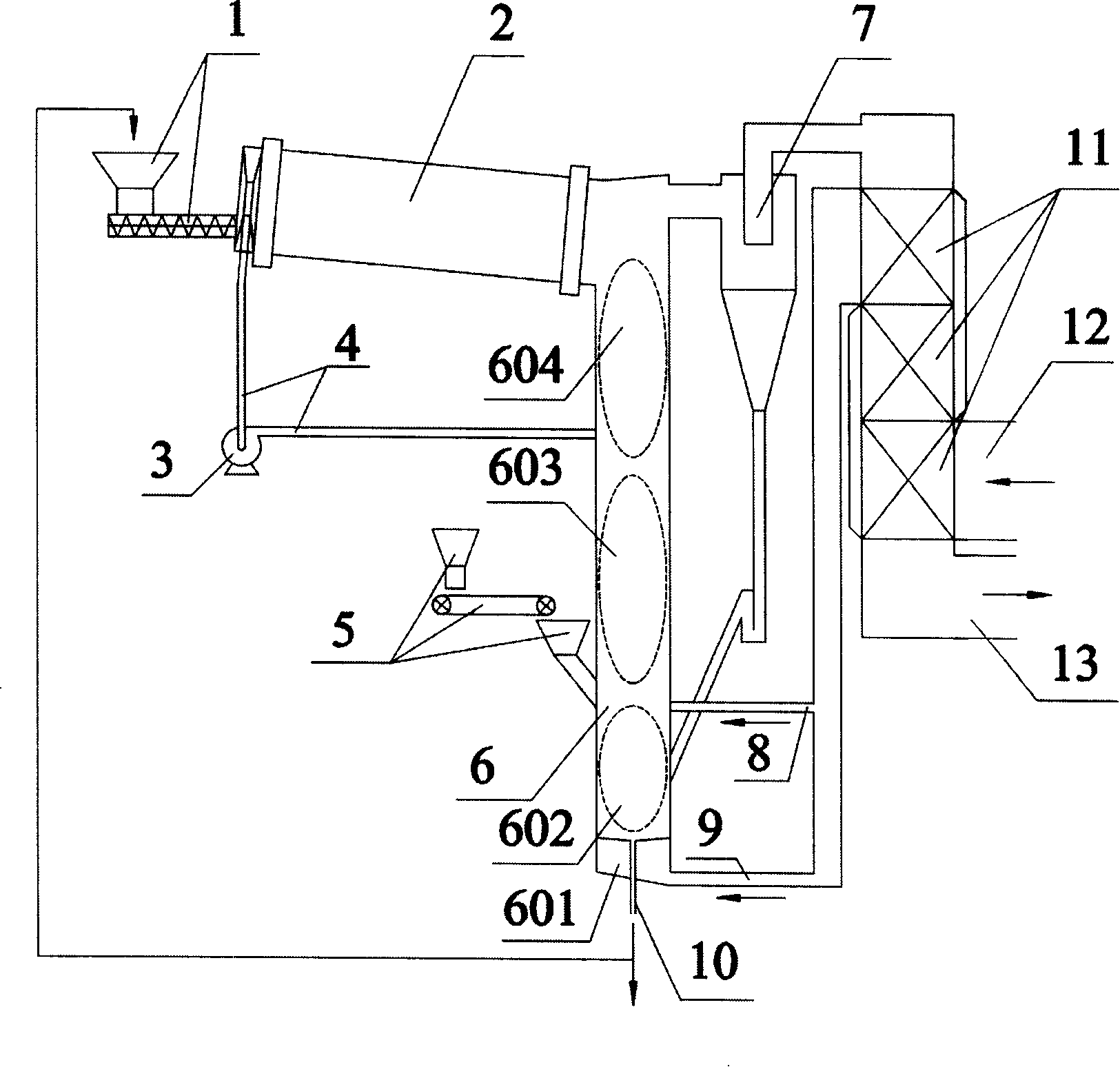

[0017] Such as figure 1 As shown, the sludge drying and incineration integrated treatment method of the present invention includes a step of utilizing the fluidized bed incinerator 6 to incinerate the sludge, wherein, in the process of utilizing the fluidized bed incinerator 6 to incinerate the sludge Before the step is carried out, the sludge is transported to a rotary sludge drying device 2, and the medium-temperature hot flue gas in the upper space of the dilute phase area of the fluidized bed incineration device 6 is introduced into the rotary sludge drying device. In the device 2, the moisture in the sludge is heated and evaporated by using the medium-temperature hot flue gas, and the obtained semi-dried sludge is sent into the fluidized bed incinerator 6, and the sewage is incinerated in the fluidized bed incinerator 6. In the mud step, the low-temperature flue gas containing organic waste gas from the rotary sludge drying device 2 is transported to the upper space of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com