Secondary air system of circulating fluidized bed household garbage incinerator

A technology of domestic waste incineration and circulating fluidized bed, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of uneven flue gas flow, low SNCR efficiency, long secondary air distance between front and rear walls, etc. The effect of reducing agent unit consumption, improving burnout rate and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

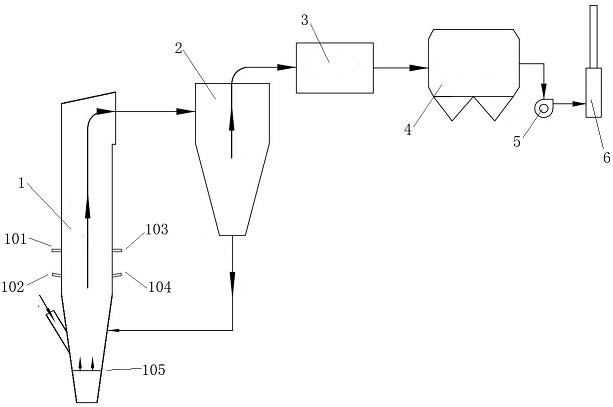

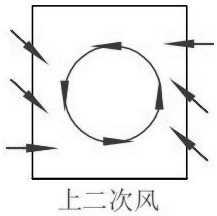

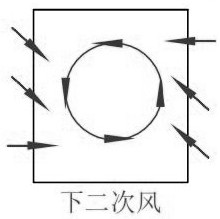

[0025] figure 1 It is a schematic diagram of the secondary air system of a circulating fluidized bed domestic waste incinerator, where the arrows indicate the process of waste treatment. Household garbage enters the furnace 1 from the side feed port for combustion, and forms high-temperature flue gas after combustion in the furnace 1, and then enters the cyclone dust collector 2 for gas-solid separation. The separated solids are partially recycled and re-enter the furnace for combustion. The high-temperature flue gas enters the flue gas purification device 4 after heat exchange and cooling with the boiler feed water in the waste heat boiler 3 , where most harmful substances are removed, and finally is discharged into the atmosphere through the induced draft fan 5 and the chimney 6 . The primary air is passed by the primary fan throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com