Metamaterial microstrip line based radiation-proof mobile phone enclosure

A technology of anisotropic medium and microstrip line, which is applied in the direction of telephone structure, electrical components, magnetic field/electric field shielding, etc., can solve the problems of reducing antenna human body radiation, poor practicability, and limited application range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

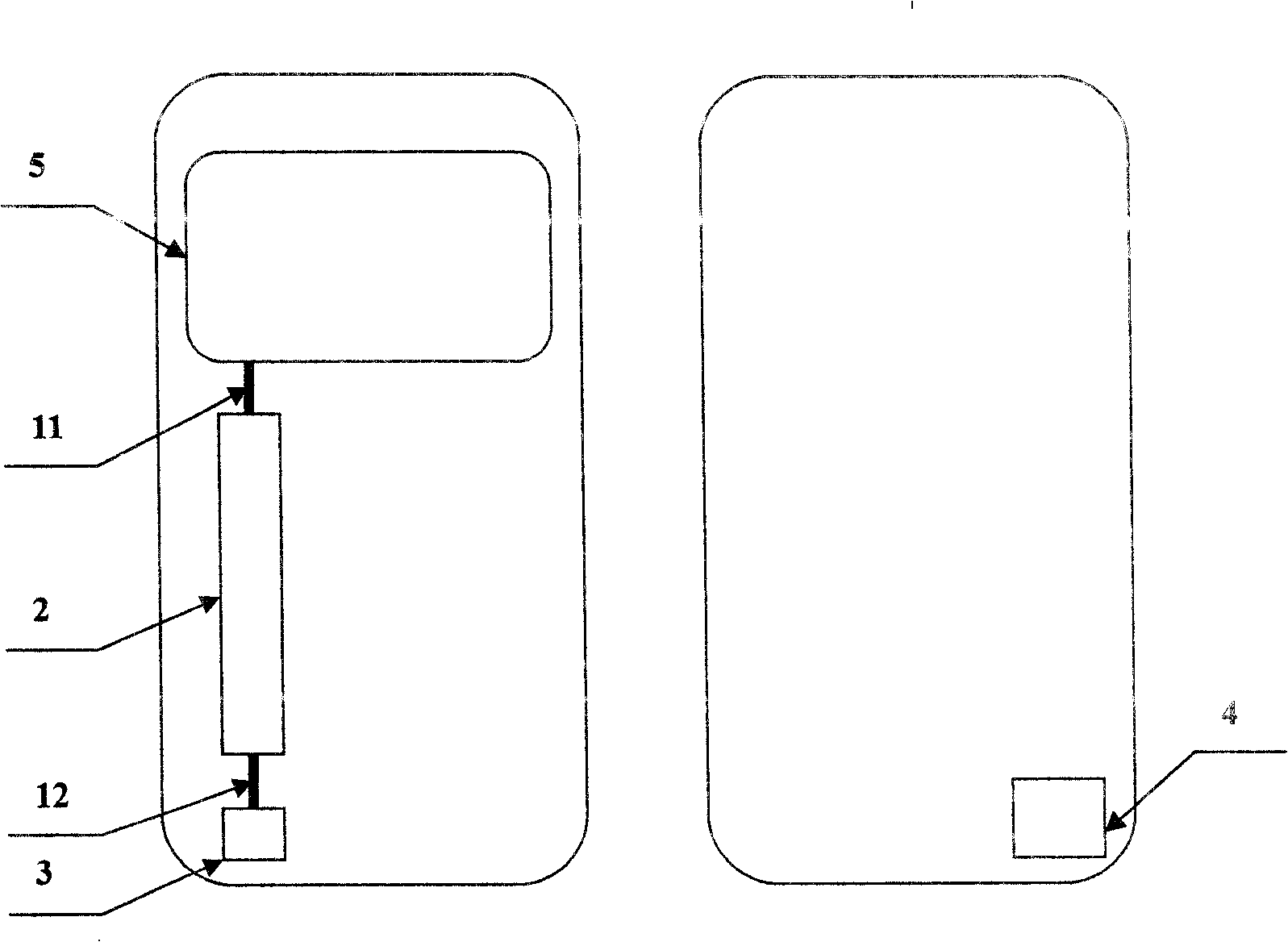

Embodiment 1

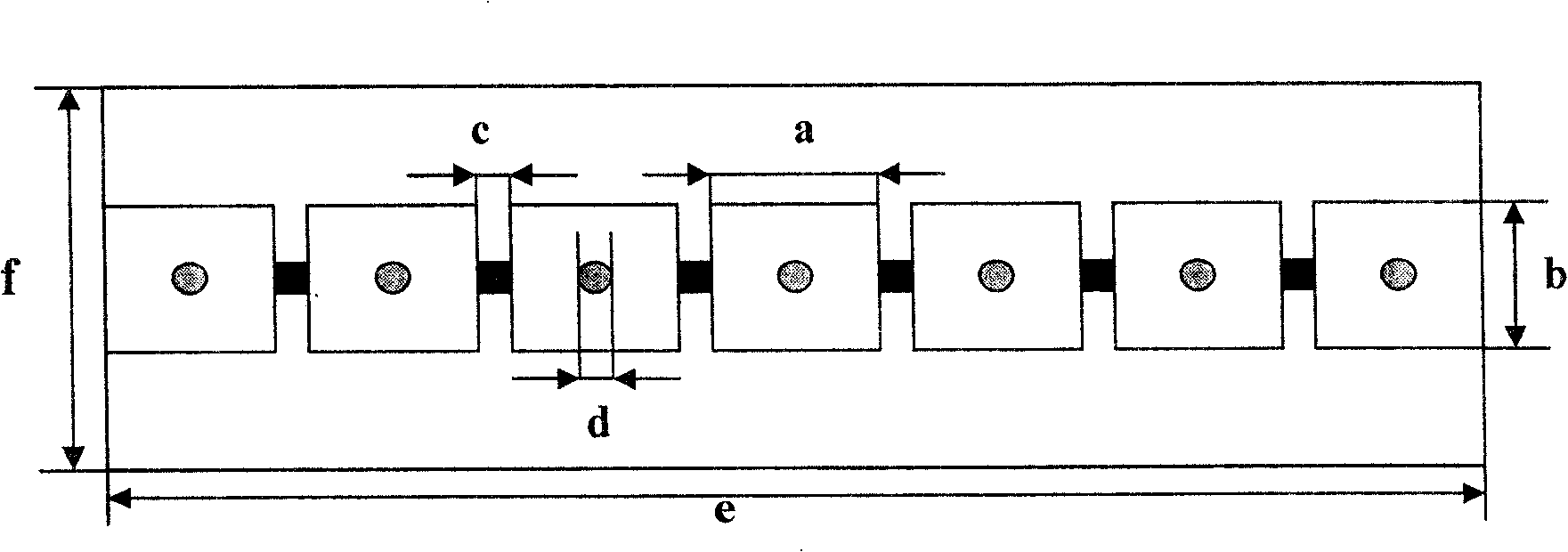

[0021] Using circuit board etching technology to make anisotropic dielectric microstrip line substrate, choose epoxy phenolic resin copper-clad dielectric board, its dielectric constant is = 4.65, board length e = 34.238mm, width f = 7mm, and the thickness of the dielectric substrate is 1.5 mm, the thickness of double-sided copper clad is 0.018mm. Select one side of the substrate as the ground plane, and etch 7 rectangular metal pieces of equal size on the other side along the center line, the length of each metal piece is a=4.238mm, the width b=2.8mm, and the width of the gap between the pieces is c = 0.762 mm. Solder 6 chip capacitors with C=2.0pF in the center of the gap between adjacent metal sheets in sequence, and the two ends are respectively connected to the adjacent metal sheets. And drill a through hole with d=1.2mm in the center of each metal sheet, and then insert a chip inductor of L=1.0nH into each through hole, weld the upper end with the metal sheet, and conne...

Embodiment 2

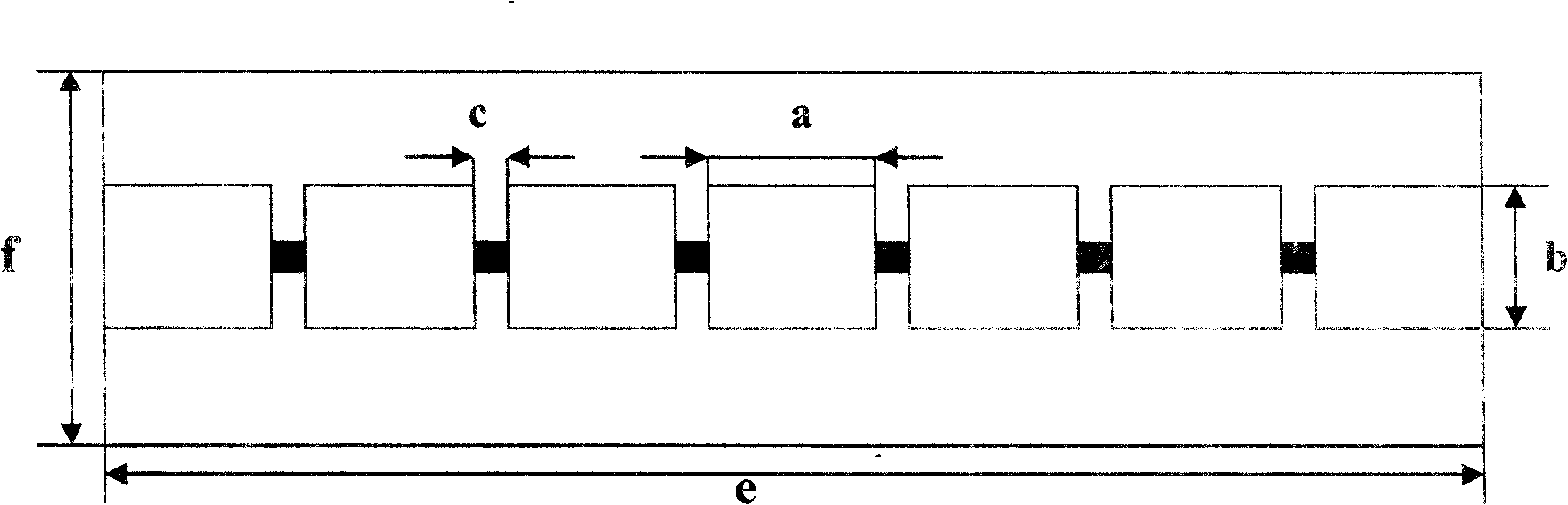

[0023] Using circuit board etching technology to make anisotropic dielectric microstrip line substrate, choose epoxy phenolic resin copper-clad dielectric board, its dielectric constant is = 4.65, board length e = 34.238mm, width f = 7mm, and the thickness of the dielectric substrate is 1.5 mm, the thickness of double-sided copper clad is 0.018mm. Select one side of the substrate as the ground plane, and etch 7 rectangular metal pieces of equal size on the other side along the center line, the length of each metal piece is a=4.238mm, the width b=2.8mm, and the width of the gap between the pieces is c = 0.762 mm. Weld 6 chip capacitors with C=1.0pF in the center of the gap between adjacent metal sheets in turn, and the two ends are respectively connected to the adjacent metal sheets. In this way, a new type of microstrip transmission line with negative magnetic permeability is produced. image 3 shown. After testing, the S21 transmission curve of the microstrip line is as at...

Embodiment 3

[0025] Using circuit board etching technology to make anisotropic dielectric microstrip line substrate, choose epoxy phenolic resin copper-clad dielectric board, its dielectric constant is = 4.65, board length e = 34.238mm, width f = 7mm, and the thickness of the dielectric substrate is 1.5 mm, the thickness of double-sided copper clad is 0.018mm. Select one side of the substrate as the ground plane, and etch 7 rectangular metal pieces of equal size on the other side along the center line, the length of each metal piece is a=4.238mm, the width b=2.8mm, and the width of the gap between the pieces is c = 0.762 mm. Drill a through hole of d=1.2mm in the center of each section of metal sheet, and then insert a chip inductor of L=1.0nH into each through hole, weld the upper end with the metal sheet, and connect the lower end with the ground plate .In this way, a new type of negative dielectric constant microstrip transmission line is produced. Figure 4 shown. After testing, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com