Package, subassembly and methods of manufacturing thereof

A technology of sub-assemblies and subassemblies, applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, electrical components, etc., can solve the problems of reducing substrates, easy to break, fragile silicon substrates, etc., to reduce assembly costs and complexity, The effect of reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

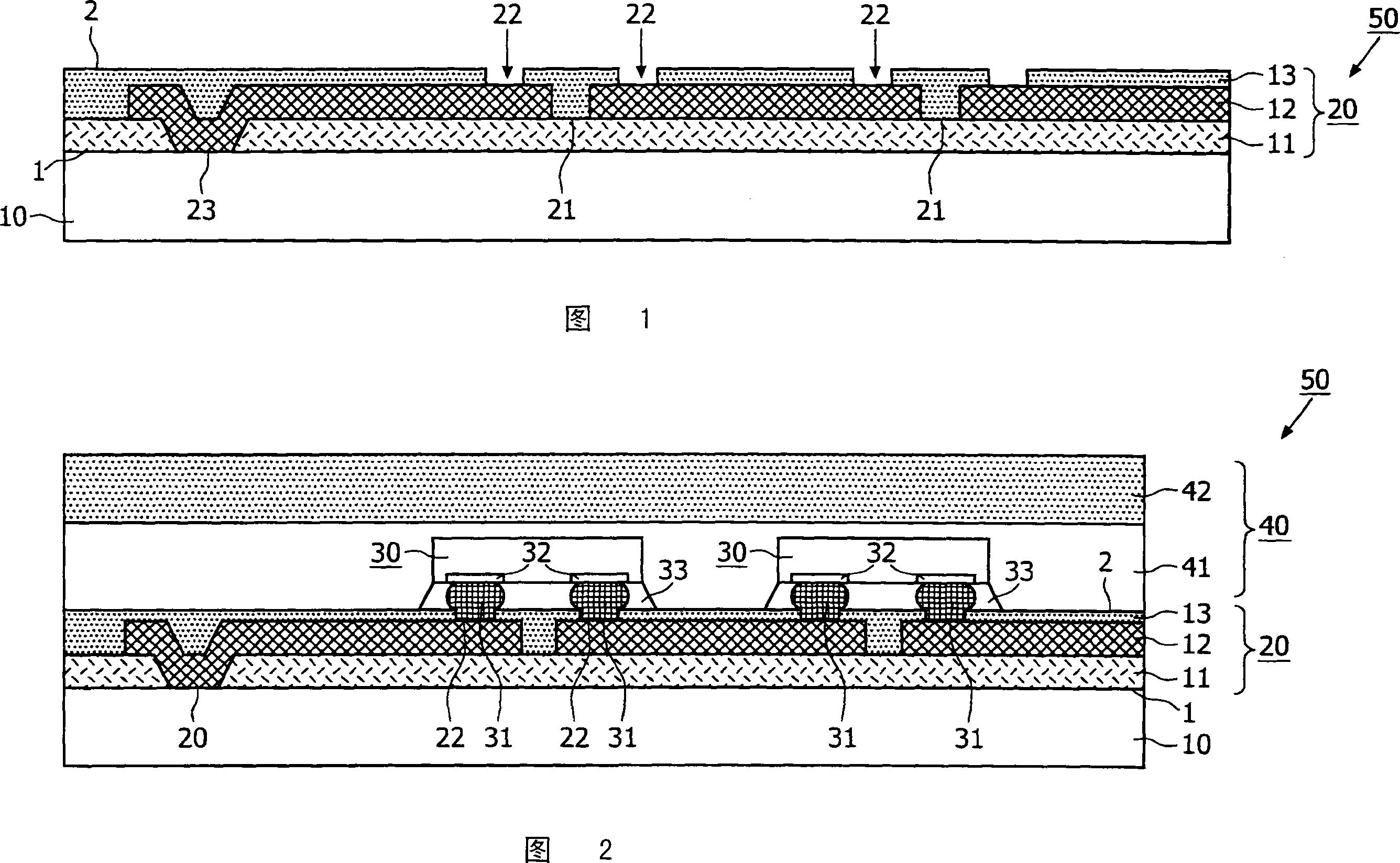

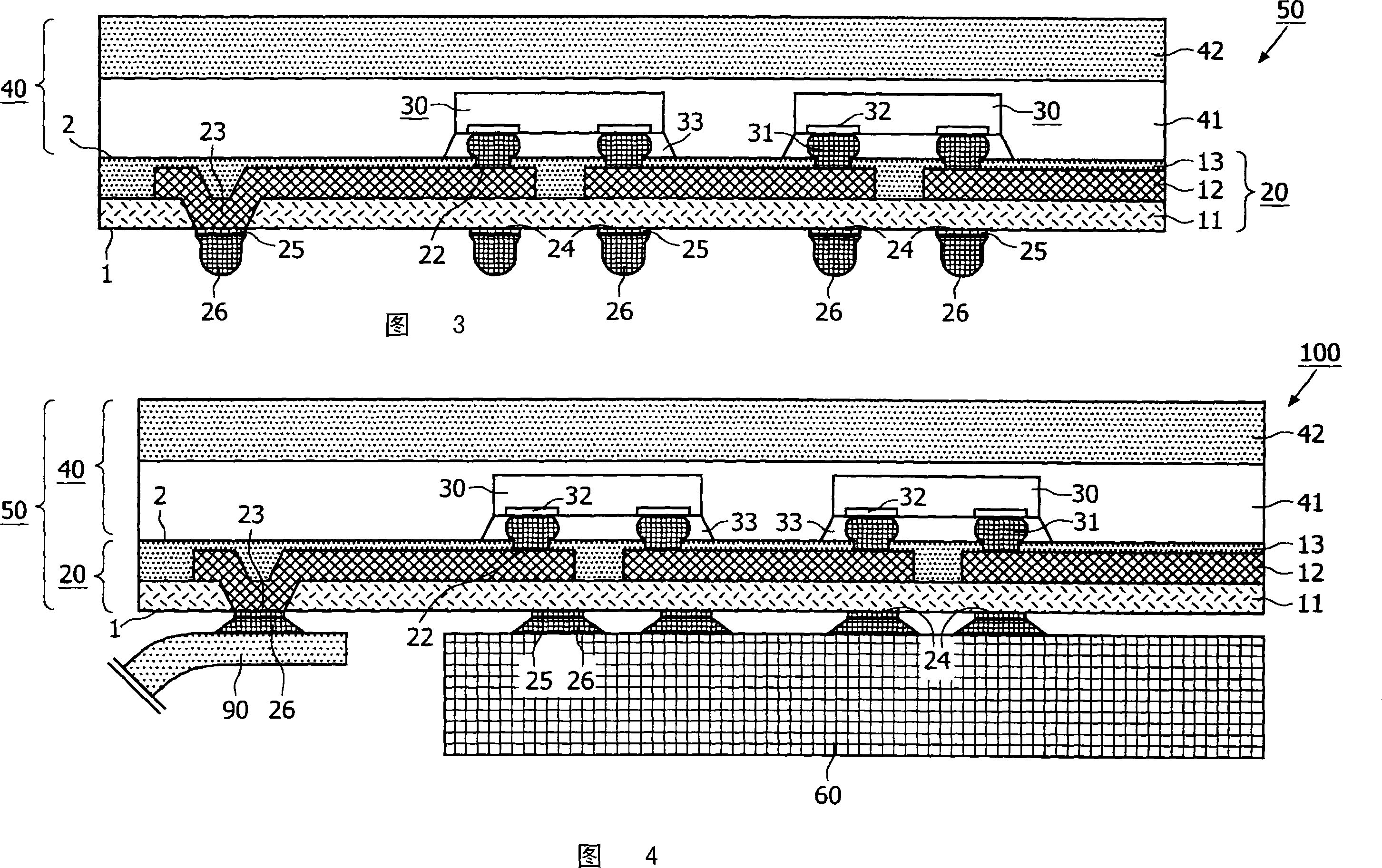

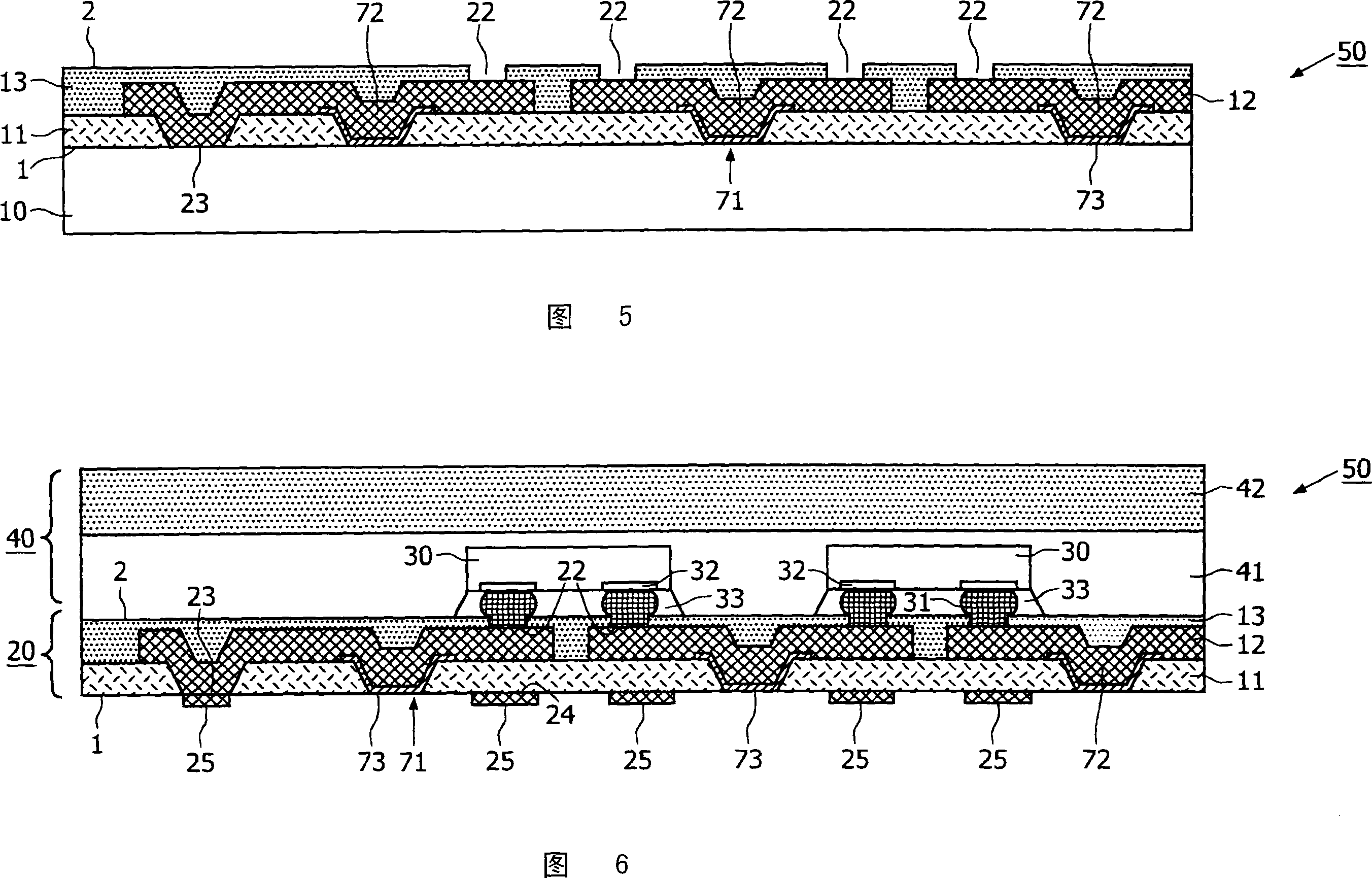

[0028] The drawings are not drawn to scale and are schematic only. The same reference numerals in different figures relate to equal or corresponding parts. The drawings are drawn for purposes of illustration only and are not to be construed as limiting the invention. Indeed, many more examples will be apparent to those skilled in the art based on the description of these figures. Although these figures show only a few stages in the fabrication of a single device, it has been found that these steps in the process generally occur at the plate level, after which breakup into individual elements occurs. This splitting can be accomplished using conventional techniques. It is appropriate that the splitting channels have been specifically defined in the subassembly 50, 150 during the manufacturing process.

[0029]FIG. 1 shows a cross-sectional view of a first stage in the manufacture of a subassembly 50 including a package but not including a heat sink. The subassembly 50 at thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com