Medium temperature thick-wall WB36/1Cr18Ni9Ti dissimilar steel welding technology

A technology of WB36 and welding process, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problem of size increase, different operating conditions, and unsuitable welding of large-diameter pipe thick-walled A/P dissimilar steel joints, etc. problems, to achieve the effect of improving production efficiency, saving construction time, and improving welding production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

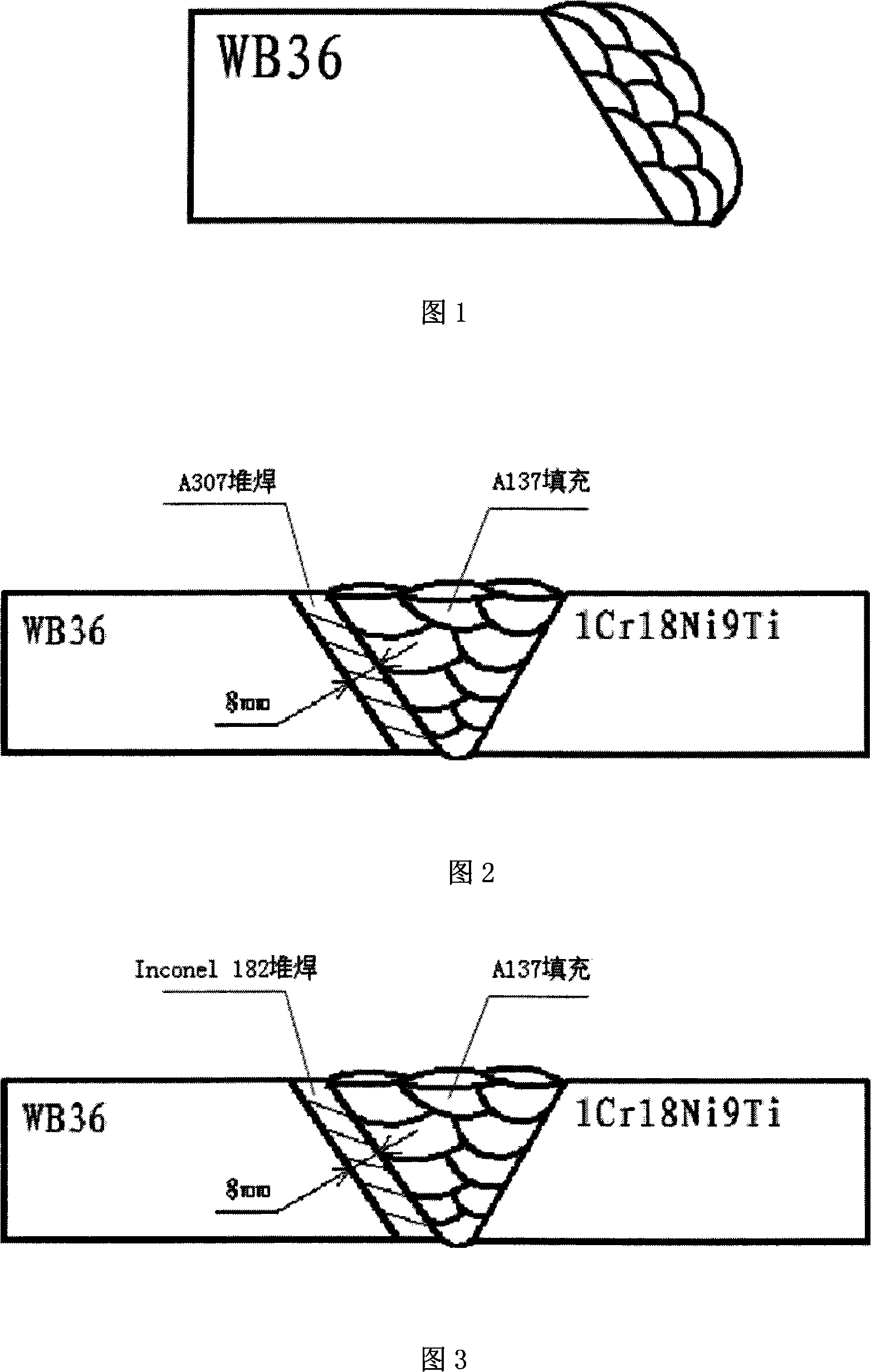

[0029] Take a workpiece with a thickness of 20mm as an example:

[0030] (1) The layout and parameters of the surfacing isolation layer are shown in Figure 1 and Table 1.

[0031] Table 1 Process parameters of isolation layer surfacing welding

[0032]

[0033] (2) The weld bead layout and parameters of butt filling are shown in Figure 2 and Table 2.

[0034] Table 2 A137 electrode filler layer surfacing process parameters

[0035] Solder layer

[0036] Fourth floor

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com