Diamond grinding tool and preparation thereof

A manufacturing method and diamond technology, applied in abrasives, manufacturing tools, metal processing equipment, etc., can solve problems such as poor bonding force, complicated manufacturing process, and increased manufacturing costs, and achieve prolonging service life. The method is simple, effective, and low-cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

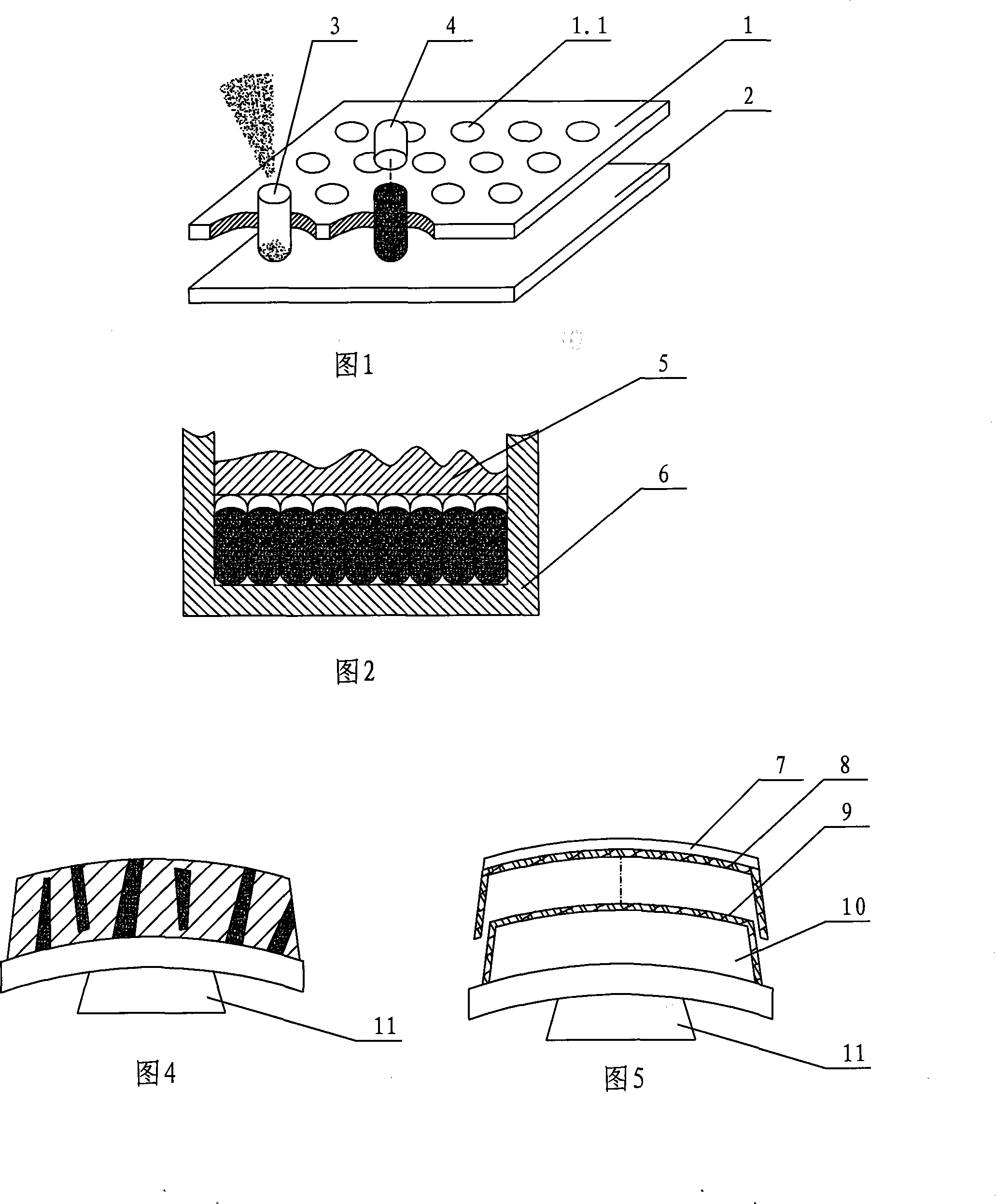

[0021] 1-3, the grinding layer 7 of this diamond grinding tool includes a diamond grinding block embedded in a resin matrix, and the diamond grinding block is an upright, curved or inclined cylinder, prism, circular truncated cone, truncated cone or truncated pyramid Its surface is provided with irregular multi-layer folded embossing, and the top and / or bottom of the diamond grinding block is provided with protrusions. The resin matrix and the diamond grinding block are formed on the clamping head 11 .

[0022] During production, firstly, the pre-configured diamond powder is filled into the capsule, and the capsule is in the shape of a cylinder, a prism, a truncated cone, a truncated cone or a truncated pyramid. The lower bag 3 in the capsule is placed in the material holding hole 1.1 of the feeding tray 1, and its bottom end abuts on the feeding tray 2. When the diamond powder fills the lower bag, the upper bag 4 is covered. Then the whole capsule is placed in the inner cavi...

no. 2 example

[0024] Referring to FIG. 4 , the resin matrix and the diamond grinding block are formed on the nylon wire layer 8 or the nylon hook layer 9 to become a grinding layer, and the grinding layer is tightly bonded to the nylon wire layer or the nylon hook layer as a whole. The corresponding nylon hook layer or nylon thread layer is arranged on the top surface and / or the side surface of the intermediate body 10 , and the intermediate body is connected with the clamping head 11 . The intermediate body 10 is an elastic body or a rigid body.

[0025] For the rest of the unmentioned parts, see the first embodiment and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com