Paulownia wood core material for laminated structure

A sandwich structure, paulownia wood technology, applied in the field of materials, can solve the problems of limited Balsa balsa resources, unrealistic import and high price, and achieve the effect of price advantage, low cost and wide range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

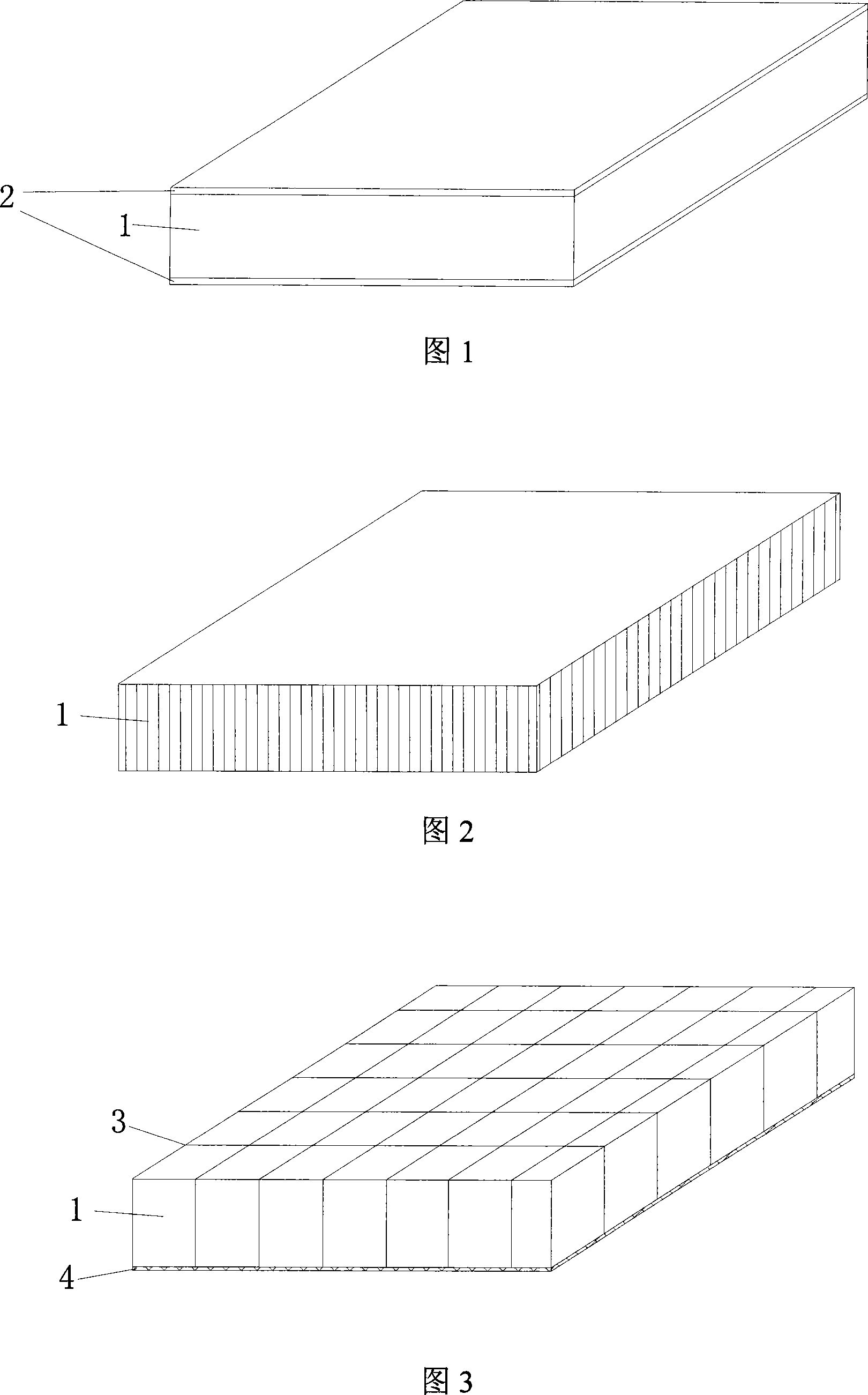

[0025] The Paulownia wood flat core material of the present invention adopts Paulownia wood resources, which are cut, sterilized, dried, and assembled into a whole piece of Paulownia wood flat board. After the assembly is completed, the wood fibers of the Paulownia wood core material 1 are perpendicular to the direction of the panel 2. The resin-based fiber panel 2 is formed by hand lay-up process on the upper and lower surfaces of the plate to form a sandwich structure plate of paulownia wood sandwich composite material.

Embodiment 2

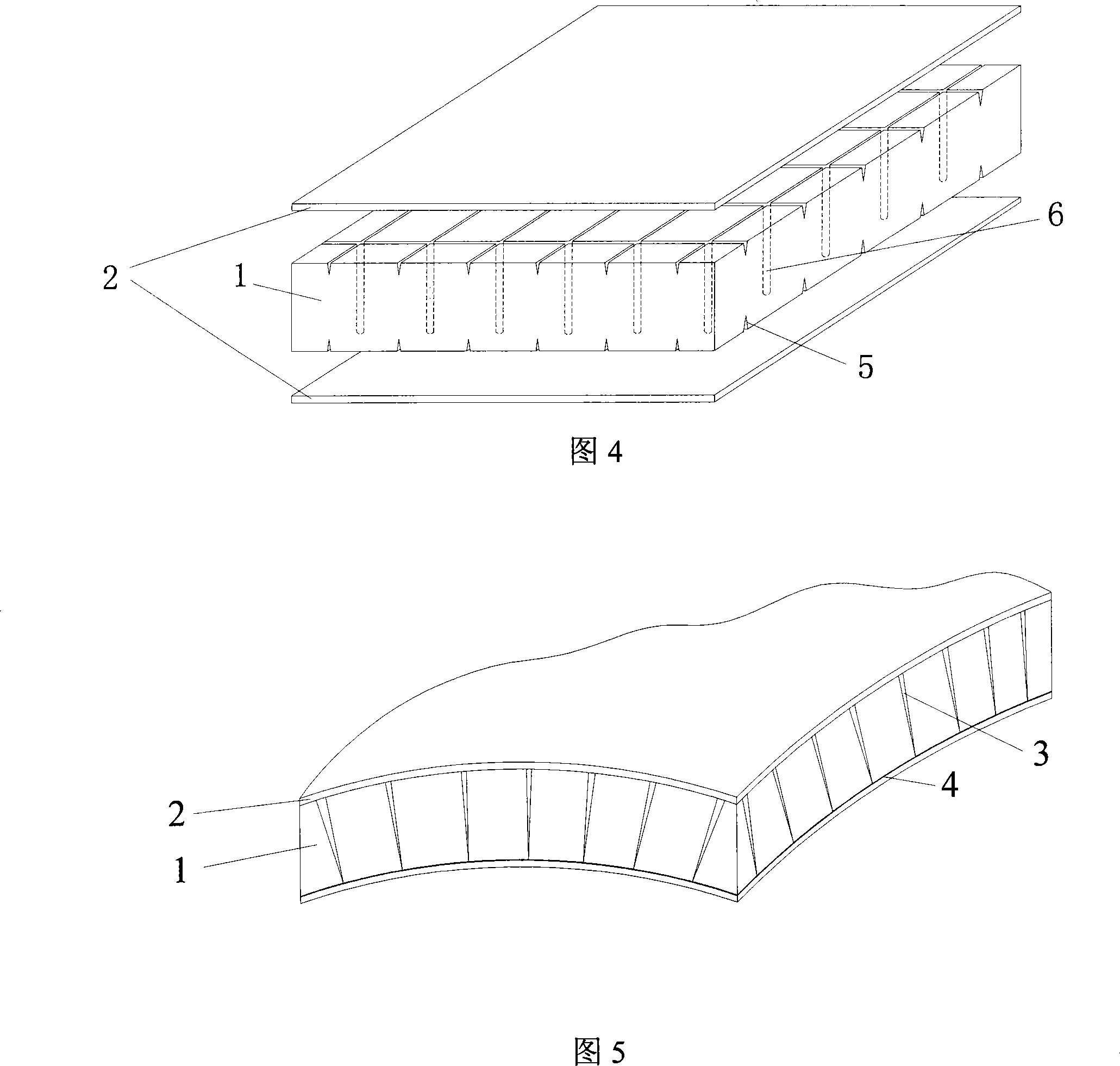

[0027] The Paulownia wood flat core material of the present invention adopts Paulownia wood resources, which are cut, sterilized, dried, and assembled into a whole piece of Paulownia wood flat board. After the assembly is completed, the wood fibers of the Paulownia wood core material 1 are perpendicular to the direction of the panel 2. The upper and lower surfaces of the wood core material 1 are provided with pointed grooves 5 arranged orthogonally, and at the same time, circular perforations are arranged at the intersection of the grooves along the thickness direction of the Paulownia wood core material 1, and the resin is formed after pouring epoxy resin. The cylinder 6 is covered with panels 2 on both sides of the core material of the paulownia wood plate. The panels 2 are formed by curing two layers of four-axis glass fiber cloth and epoxy resin, and are prepared by vacuum injection molding process.

Embodiment 3

[0029] The paulownia wood profile board core material of the present invention adopts paulownia wood resources, which are cut, sterilized, dried, and assembled into a whole piece of paulownia wood flat board. The thickness direction of 1 is cut orthogonally to form a cutting seam 3, and a thin glass fiber felt 4 is pasted on one side thereof to form a core material of a Paulownia wood profile board that can be easily formed into a shell shape, and on both sides of the Paulownia wood profile board core material Both are laid with a sandwich structure panel 2, and the panel 2 is formed by curing three layers of biaxial glass fiber cloth and vinyl resin, and is prepared by a vacuum introduction molding process.

[0030] The preparation method of the above-mentioned paulownia wood flat board and profile board core material adopts manual or industrialized production, and the preparation process is as follows:

[0031] a. Paulownia wood is sterilized, dried, cut and assembled;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com