Method for preparing vacuum glass

A technology of vacuum glass and glass, which is applied in glass manufacturing equipment, glass forming, glass reshaping, etc. It can solve the problem of difficult edge sealing and evenly distributed support columns at one time, inability to realize industrial production, inconsistent support column heights, etc. problem, to achieve the effect of reducing the heat exchange area, ensuring the vacuum degree, and simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings; the following embodiments are illustrative, not restrictive, and the protection scope of the present invention cannot be limited by the following embodiments.

[0034] A preparation method of vacuum glass, the steps of the preparation method are:

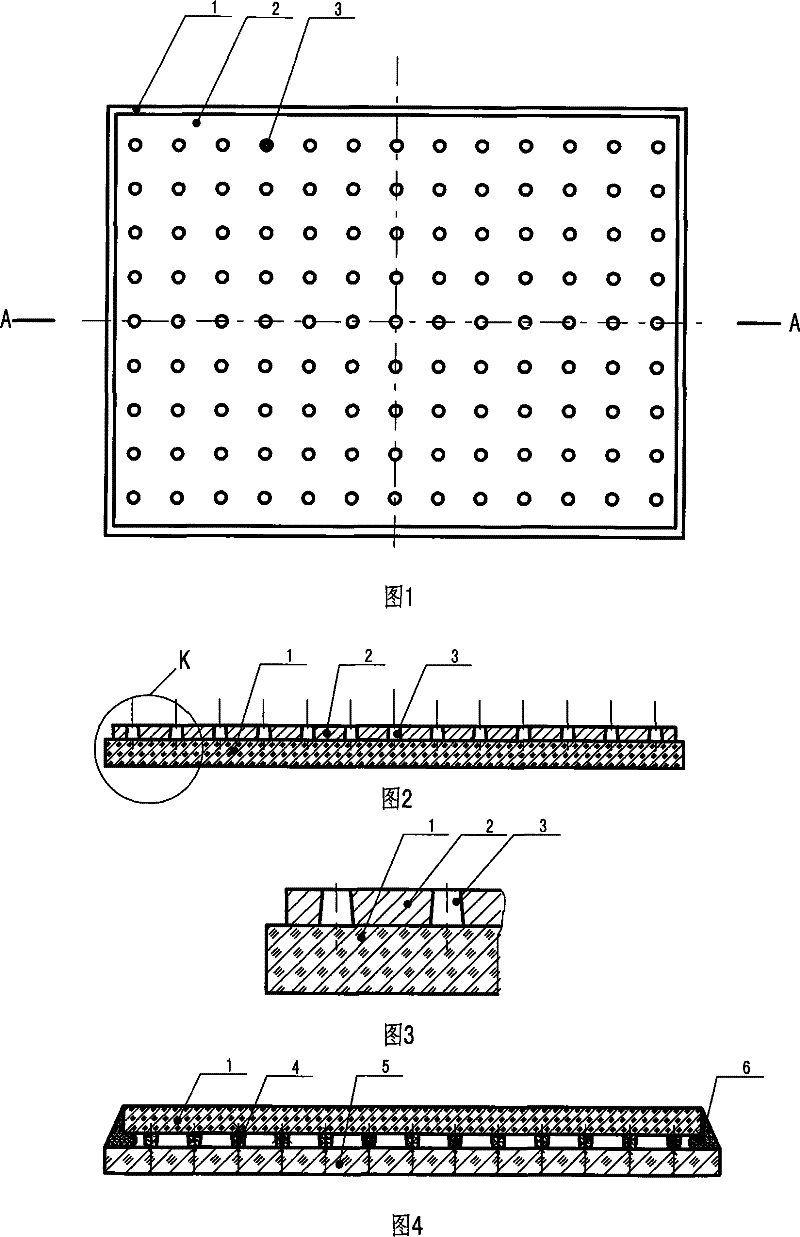

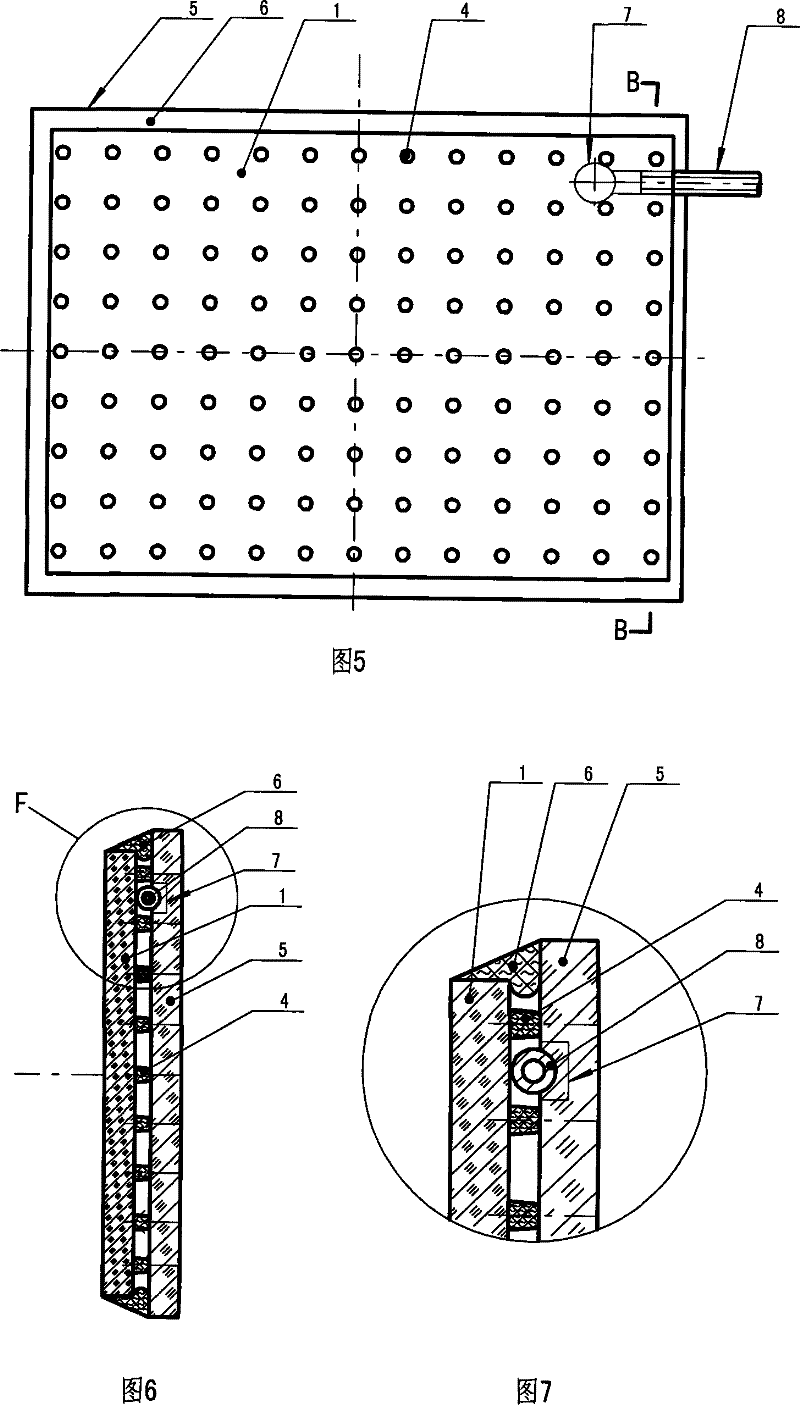

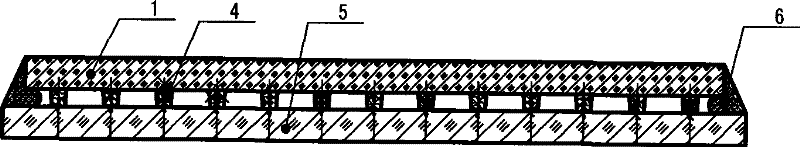

[0035] (1). Put a piece of glass as the substrate glass 1 on the workbench, and then place the bushing mold 2 with die holes 3 evenly distributed on it on the substrate glass. The bushing mold can be made of steel plate or Made of alloy and plastic with strong hardness; according to the thickness of the glass plate (1-10mm), the axis distance of the die hole is between 20-80mm, the bottom diameter is between 0.3-3mm, and the height is 0.15-0.5mm between. The cross-sectional shape of this die hole can be the positive truncated cone shape shown in the figure of this embodiment, and can also be structures such...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com