Continuous producing method and device for formic acid

A production method and formic acid technology, applied in the field of continuous production of formic acid and devices, can solve the problems of not being suitable for large-scale production, limiting the production capacity of formic acid, and increasing the production cost, so as to simplify operation, reduce production cost, reduce materials and The effect of energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

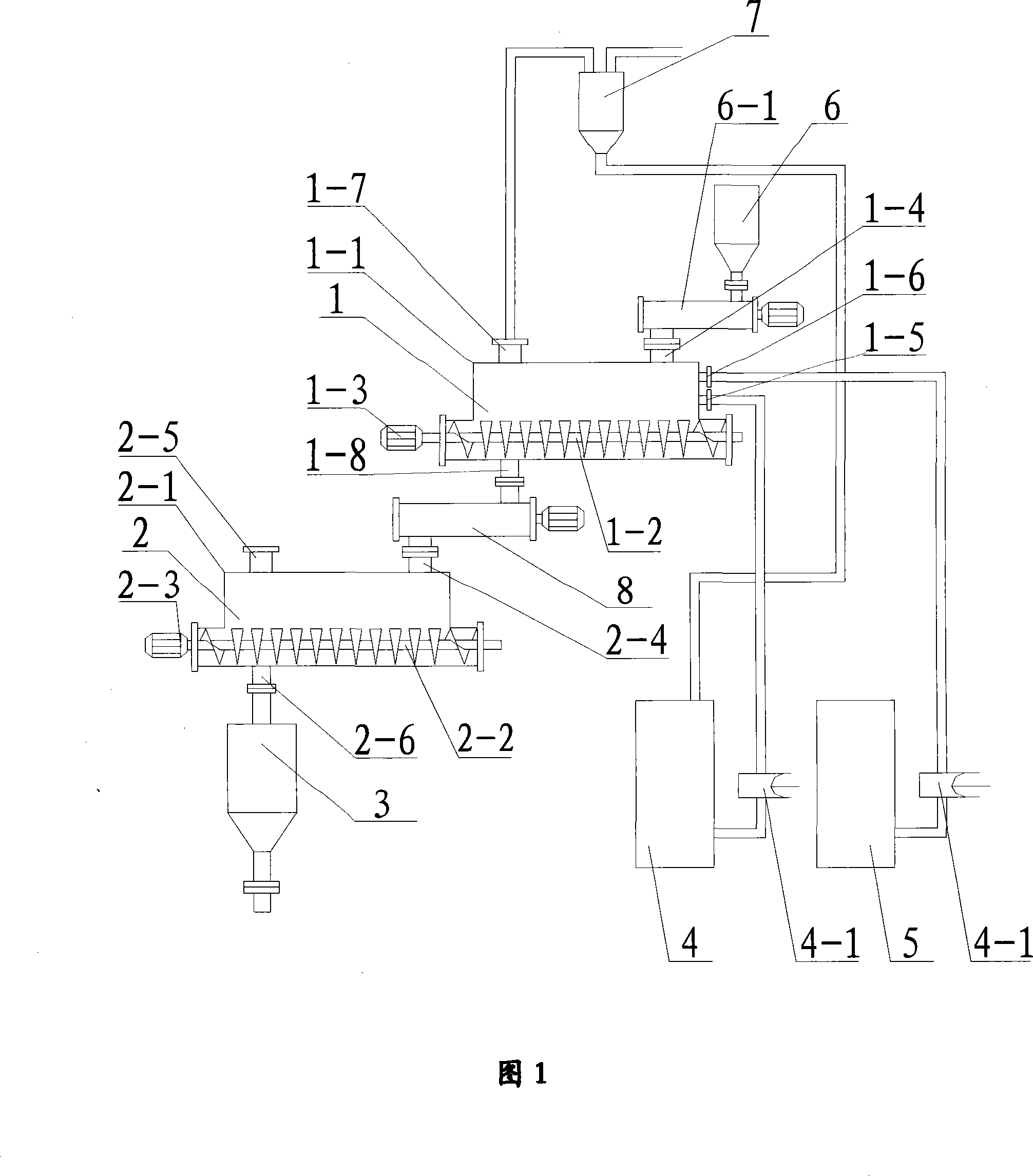

[0029] Embodiment 1: the continuous production method of formic acid, it comprises the following steps:

[0030] (1) after metering phosphoric acid, hexane and sodium formate, add in the first reactor 1 from one side of the first reactor;

[0031] (2) Make the material in the first reactor 1 spiral forward to the other side of the first reactor 1 along the horizontal direction. During the progress of the material, the temperature is 50-80°C and the pressure is 34KPa-101.3KPa. Under acidification reaction 2-3 hour, and steam acidifying auxiliary agent hexane from the upper end of the other side of the first reactor 1, discharge the crude reactant from the lower end of the other side of the first reactor 1;

[0032] (3) transport the crude reactant discharged from the bottom of the other side of the first reactor 1 to the top of one side of the second reactor 2;

[0033] (4) Make the crude reactant entering from the top on one side of the second reactor 2 spirally advance to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com