Solid fermentation process for preparing bacillus natto microecological preparation

A technology of Bacillus natto and micro-ecological preparations, applied in the field of micro-ecological preparations, can solve the problems of low number of viable bacteria and affect the growth of Bacillus natto, and achieve the effects of low production cost, stable and efficient product quality, and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

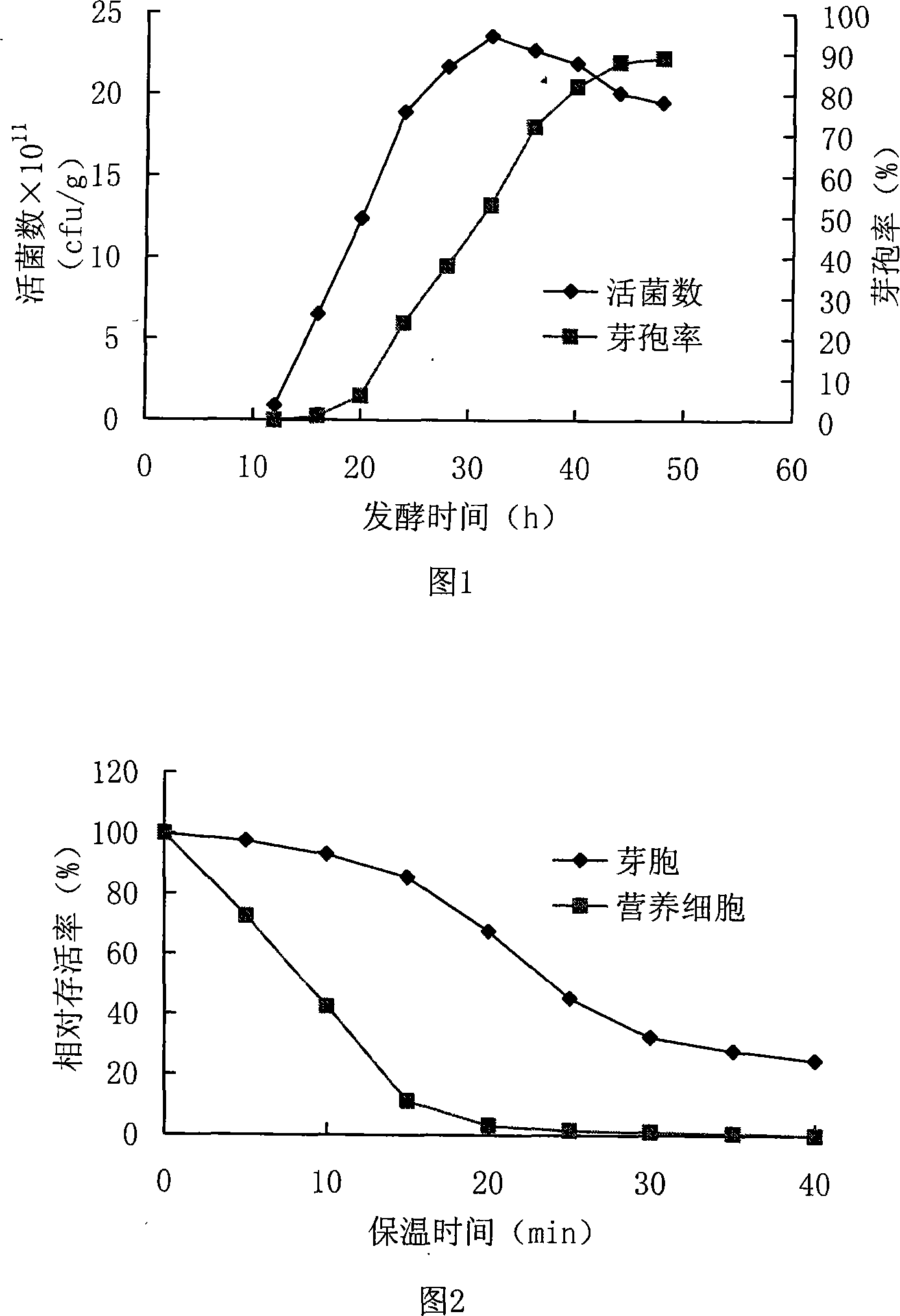

[0035] Example 1: Solid-state fermentation method of Bacillus natto probiotics

[0036] Bacillus natto CCTCC M207147 was inoculated on the slant of the broth medium and cultured at 37°C for 24h. Pick 1 ring of slant seeds and inoculate it in liquid seed culture medium (peptone 1%, beef extract 0.5%, NaCl 0.5%, pH 7.0~7.2), and cultivate on a rotary shaker at 200r.pm at 37°C for 16h to obtain the first level Seed liquid. Fill a 50L seed fermentor with 35L liquid seed culture medium, sterilize at 121°C for 15min, cool to 37°C, inoculate 1.5% first-level seed liquid, and cultivate at 37°C for 10h to obtain a second-level seed liquid. Mix 6.5 parts of bran, 2 parts of soybean meal powder, and 1.5 parts of corn starch evenly, and add the inorganic salt solution according to the solid-liquid weight ratio of 1:1.2 (the solution contains K 2 HPO 4 ·3H 2 O 1.0%, MgSO 4 ·7H 2O 0.1%), mix well, sterilize at 121°C for 30 minutes, and cool to 37°C to obtain a solid fermentation medium. The sol...

Embodiment 2

[0037] Example 2: Temperature tolerance of Bacillus natto CCTCC M207147

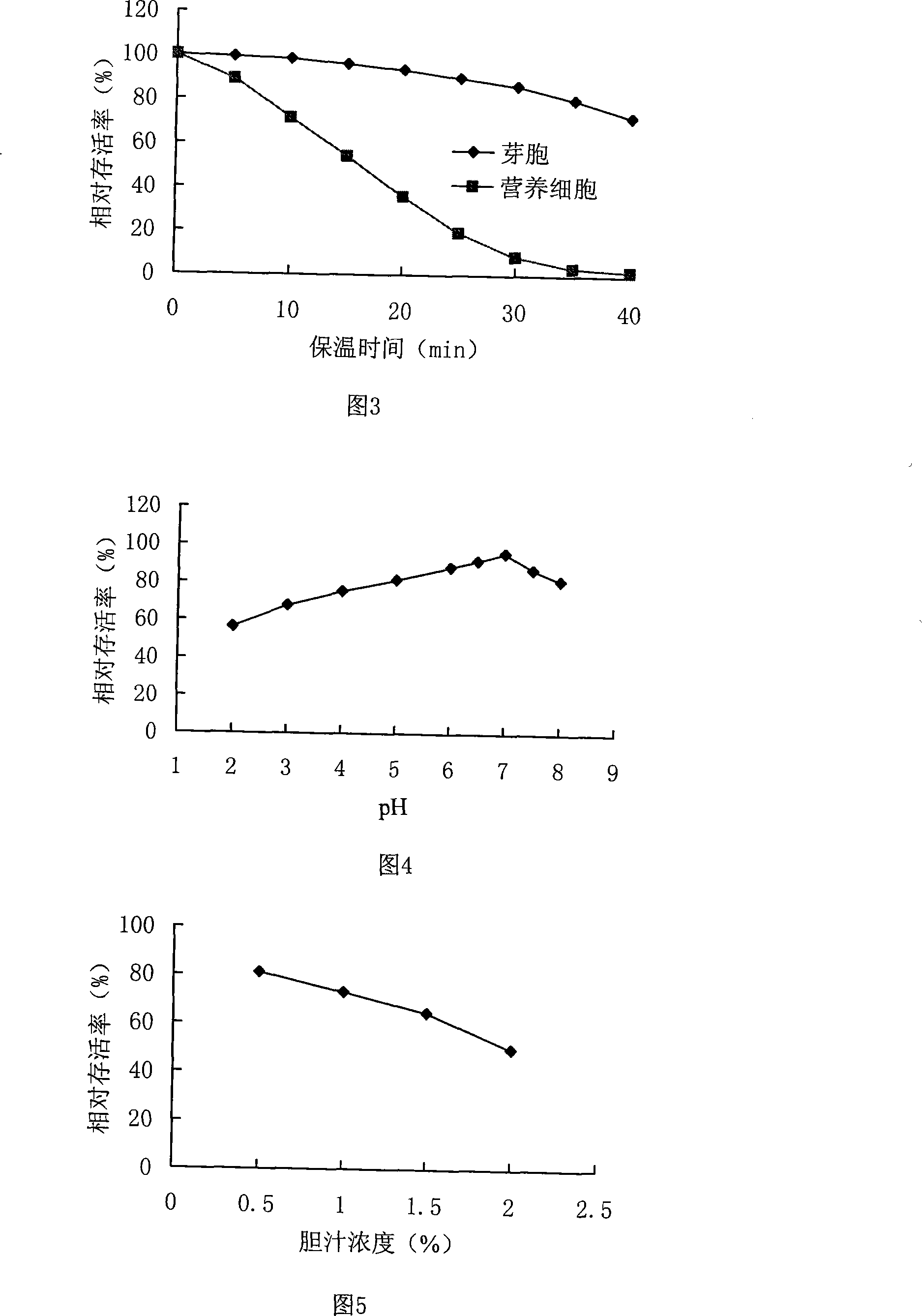

[0038] The spore liquid and nutrient bacterial liquid of Bacillus natto CCTCC M207147 were kept in a water bath at 100°C and 80°C for a period of time and then counted viable bacteria. The number of viable bacteria before the water bath was used as the control to calculate the relative survival rate. . The results are shown in Figures 2 and 3.

Embodiment 3

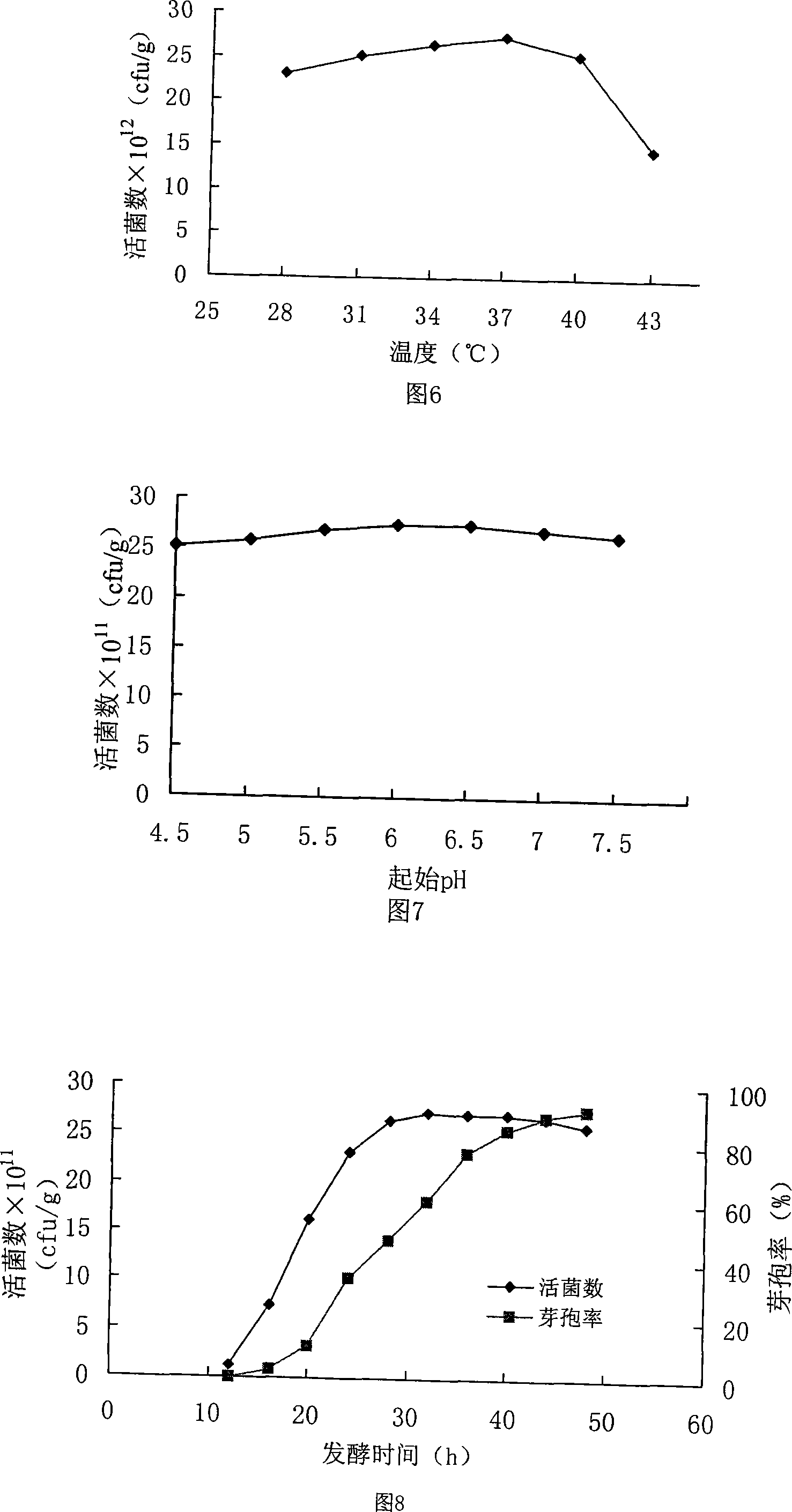

[0039] Example 3: Tolerance of Bacillus natto CCTCC M207147 to acid and alkali

[0040] The vegetative bacteria liquid of Bacillus natto CCTCC M207147 was incubated at 37°C for 45 minutes at different pHs and then counted viable bacteria. The number of viable bacteria in the untreated nutrient liquid was used as a control to calculate the relative survival rate. The results are shown in Figure 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com