Gas kitchen range energy-saving method and its structure

A technology for gas cookers and cookers, which is applied to household cookers, heating fuels, heating methods, etc., can solve problems such as low energy utilization rate and waste, and achieve the effects of low heat loss, reduced emissions, and reasonable structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

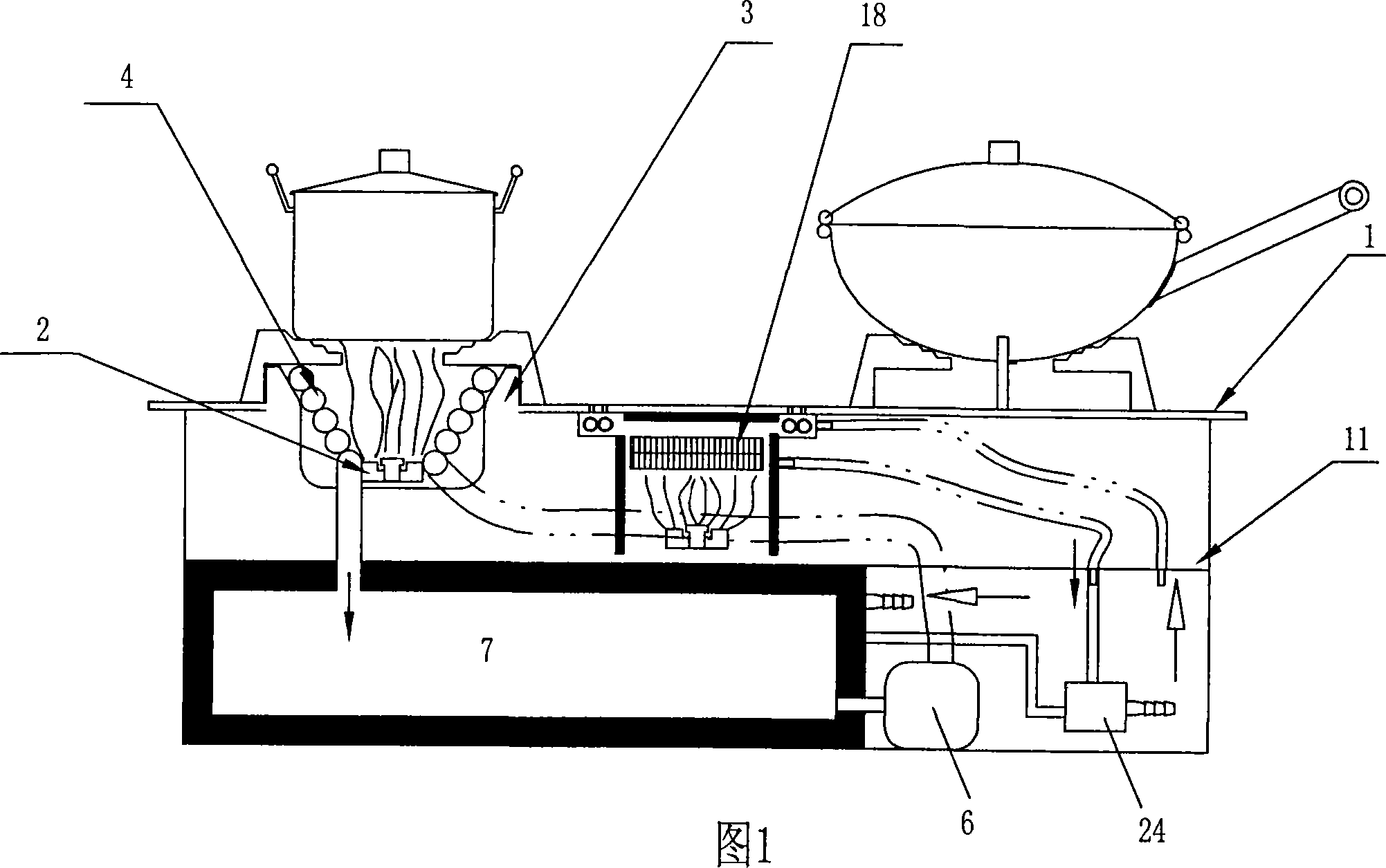

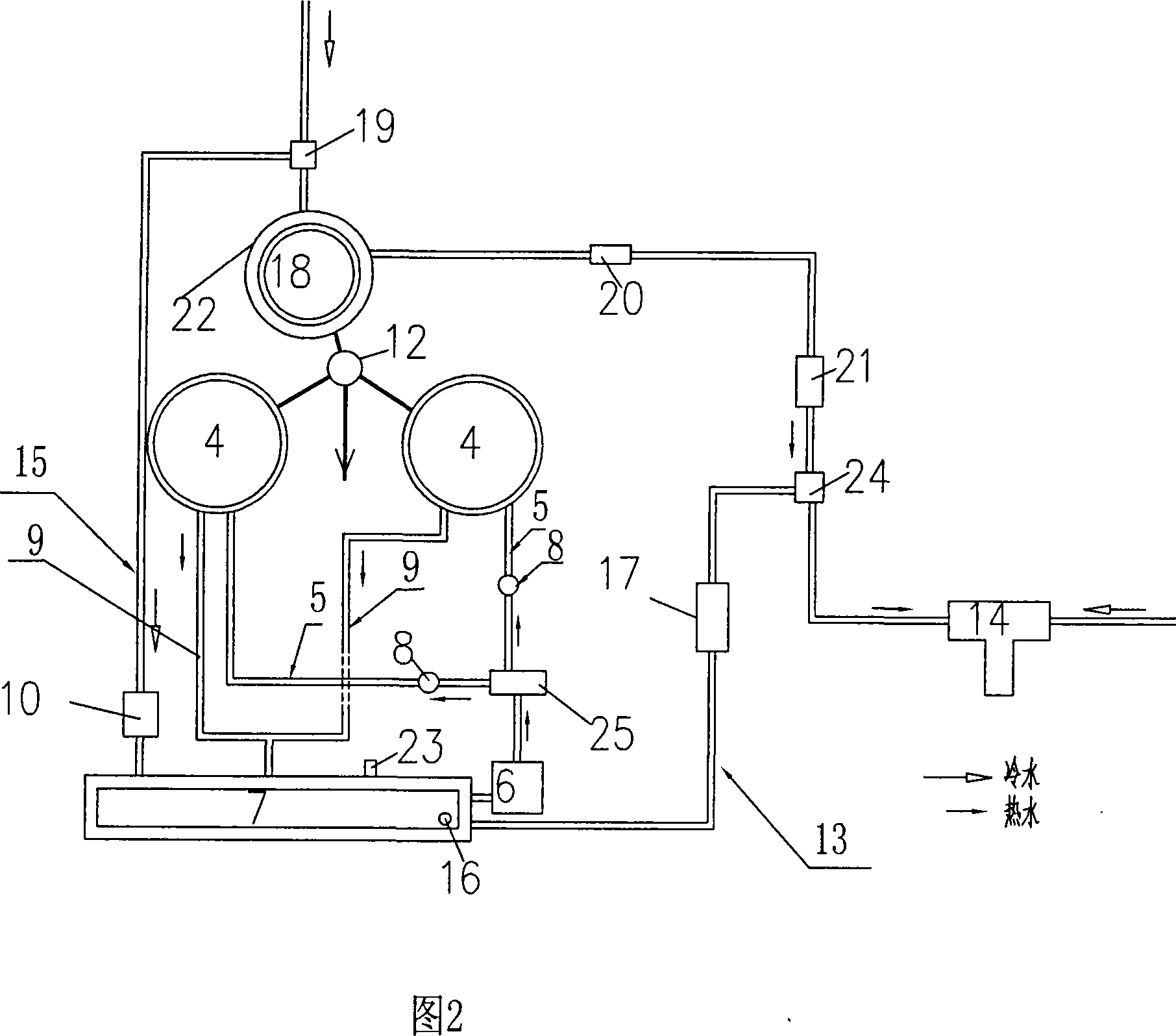

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] An energy-saving method for a gas cooker, comprising the following steps:

[0023] First, lower the burners below the cooktop;

[0024] Secondly, heat pipes are arranged around the edge of the burner to collect waste heat, and the heat pipes are surrounded by an inverted cone shape around the flame, so that the heat of the flame is concentrated to the bottom of the cooker under the action of the inverted cone heat pipes, improving the heat utilization rate;

[0025] Thirdly, circulating water is passed through the heat pipe, and the cold water in the heat pipe around the burner is heated through the heat exchange of the heat pipe, and then sent to the heat preservation water tank for standby, so as to realize waste heat recovery and energy recovery and utilization.

[0026] The energy-saving gas cooker of the present invention is shown in Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com