Polyester film for flexible printing plate

A technology of flexographic printing plate and polyester film, which is applied in printing, printing plate, printing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1. Preparation of coating solution for forming separable adhesive layer (A)

[0046] Add 100 parts by weight (based on non-volatile components) of water-dispersible polyester resin (produced by Nippon Synthesis Co.), 100 parts by weight of acrylic resin (produced by Nippon Carbide Co., Ltd.) to the pure water that has passed through the ion exchange resin , 10 parts by weight of a melamine-based crosslinking agent (manufactured by Cytec) and 2.5 parts by weight of a nonionic actylenic diol (Nissan Chemical Industries Co., Ltd.) as a surfactant, and stirring the solution to prepare a coating solution. The coating solution had a total solids content of 3.0%.

[0047] 2. Preparation of coating solution for forming antistatic layer (C)

[0048] Add 100 parts by weight of cationic polymer antistatic agent (produced by Konishi Company) composed of quaternary ammonium salt copolymerized with acrylic acid resin skeleton, 2.5 parts by weight of nonionic actylenic glycol (Ni...

Embodiment 2

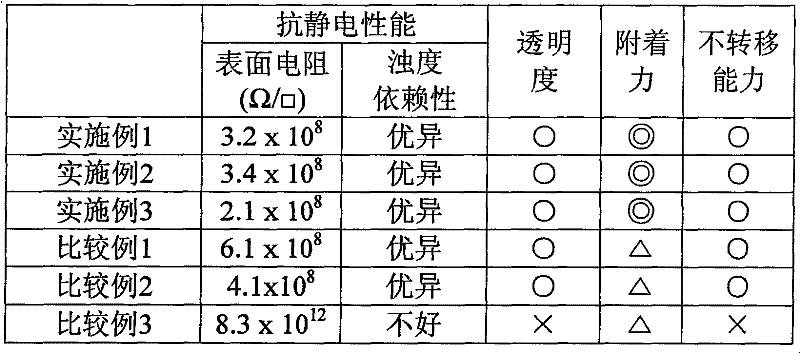

[0052] Except in the step of preparing the coating solution for forming the separable adhesive layer (A), 100 parts by weight of polyester resin (produced by Nippon Synthesis Co., Ltd.), 150 parts by weight of Acrylic resin (produced by Nippon Carbide Co.), 20 parts by weight of epoxy-based cross-linking agent (produced by Nagasechem Co.) and 1.5 parts by weight of nonionic actylenic diol (produced by Nissan Chemical Industries Co., Ltd.) as surfactant, and stirring A polyester film for a flexographic printing plate was manufactured in the same manner as in Example 1 except that the above solution was used to prepare a coating solution having a total solid content of 3.0%. The evaluation results of the polyester film are shown in Table 1 below.

Embodiment 3

[0054] Except that in the step of preparing the coating solution for forming the separable adhesive layer (A), 30 parts by weight of melamine resin (produced by Cytec Corporation) was added as a cross-linking agent, manufactured according to the same method as in Example 1 Polyester film for flexographic printing plates. The evaluation results of the polyester film are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com