A multi-channel pipe-type line type heat fire detector

A fire detector and line-type technology, which is applied in the direction of electrical fire alarms, hydraulic/pneumatic fire alarms, instruments, etc., can solve the problems of limited application range, large construction volume, and inability to exhaust them all, and achieve Save labor installation costs, save equipment investment, and increase the protection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

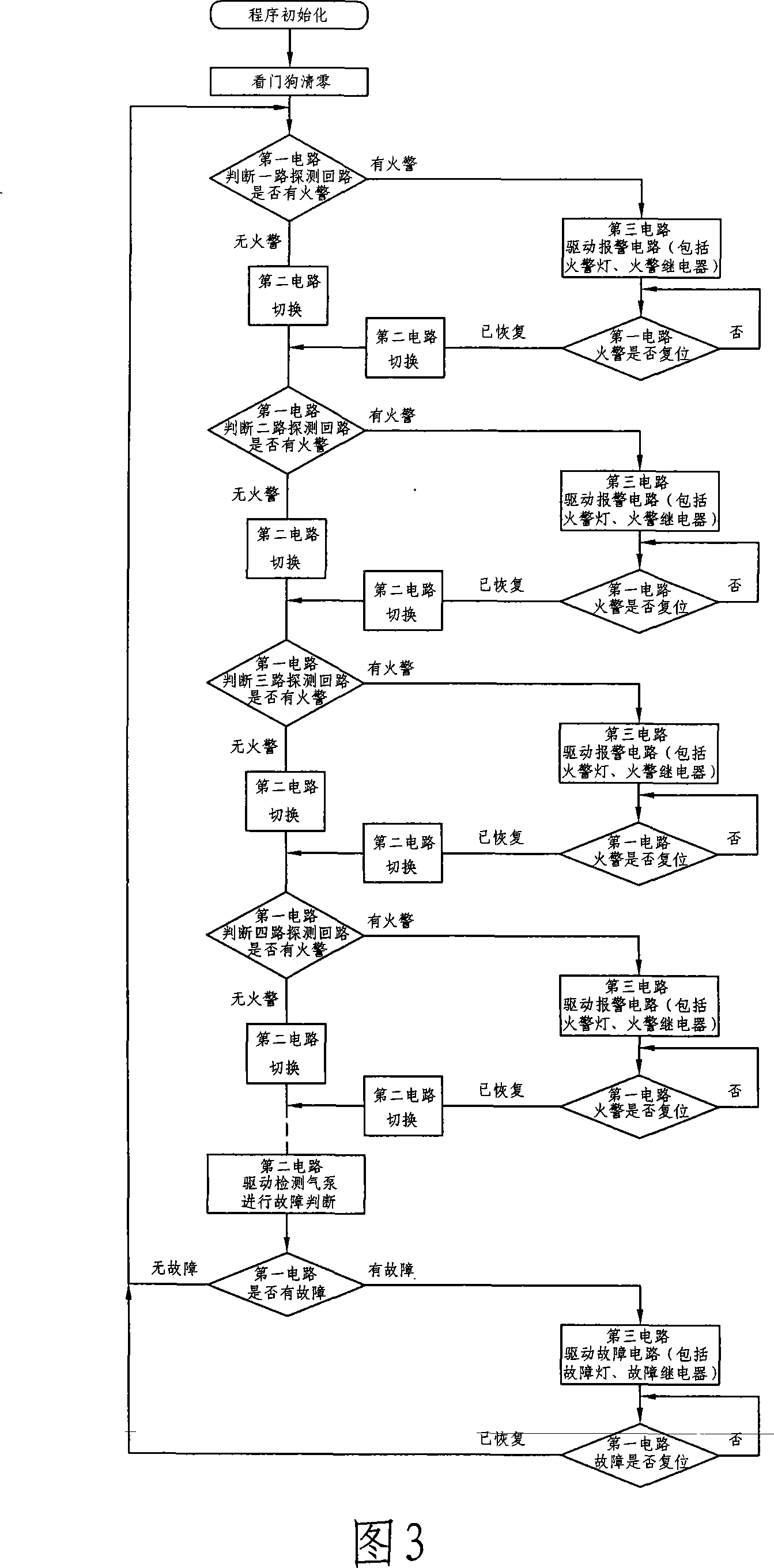

[0019] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

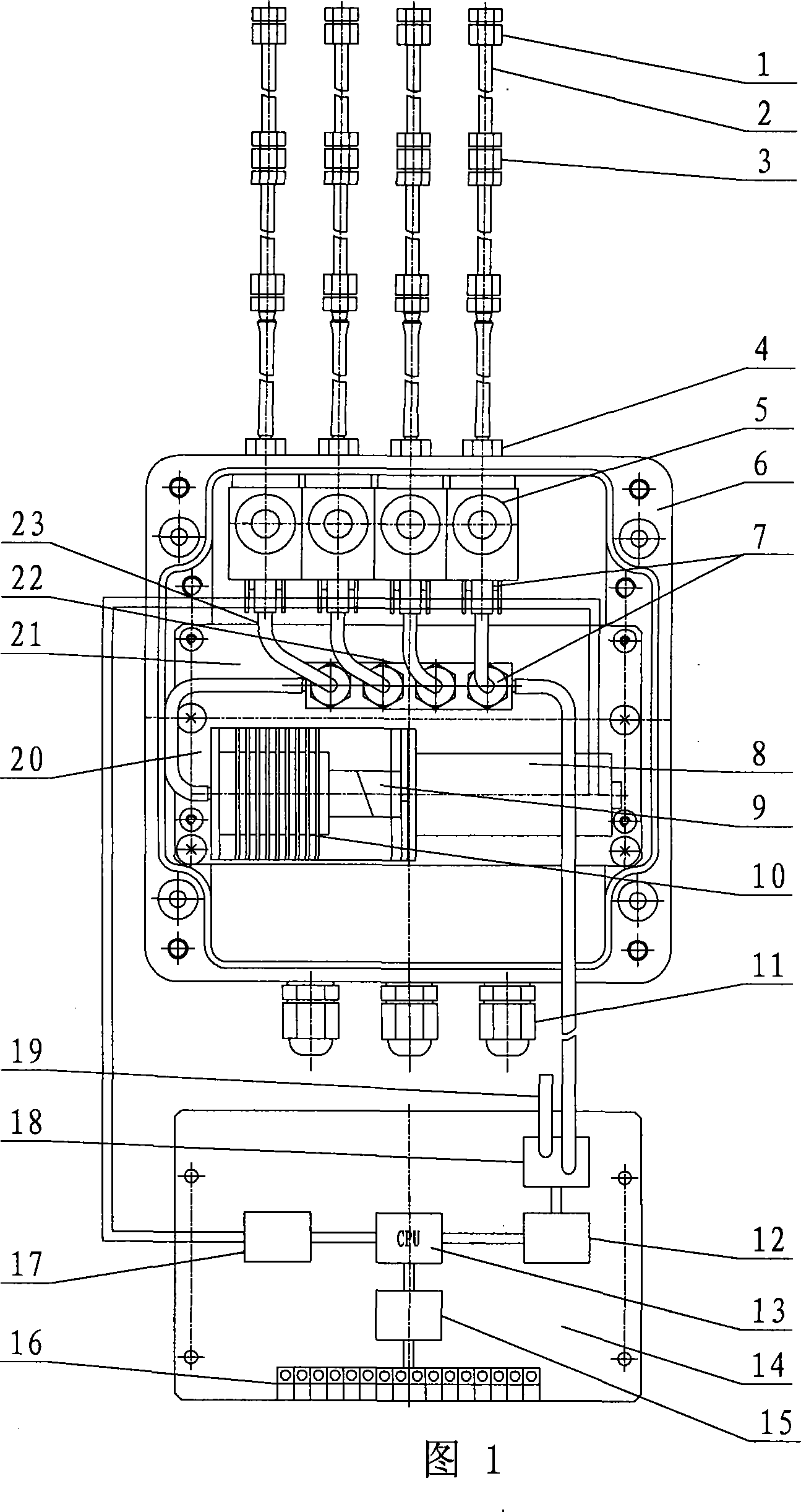

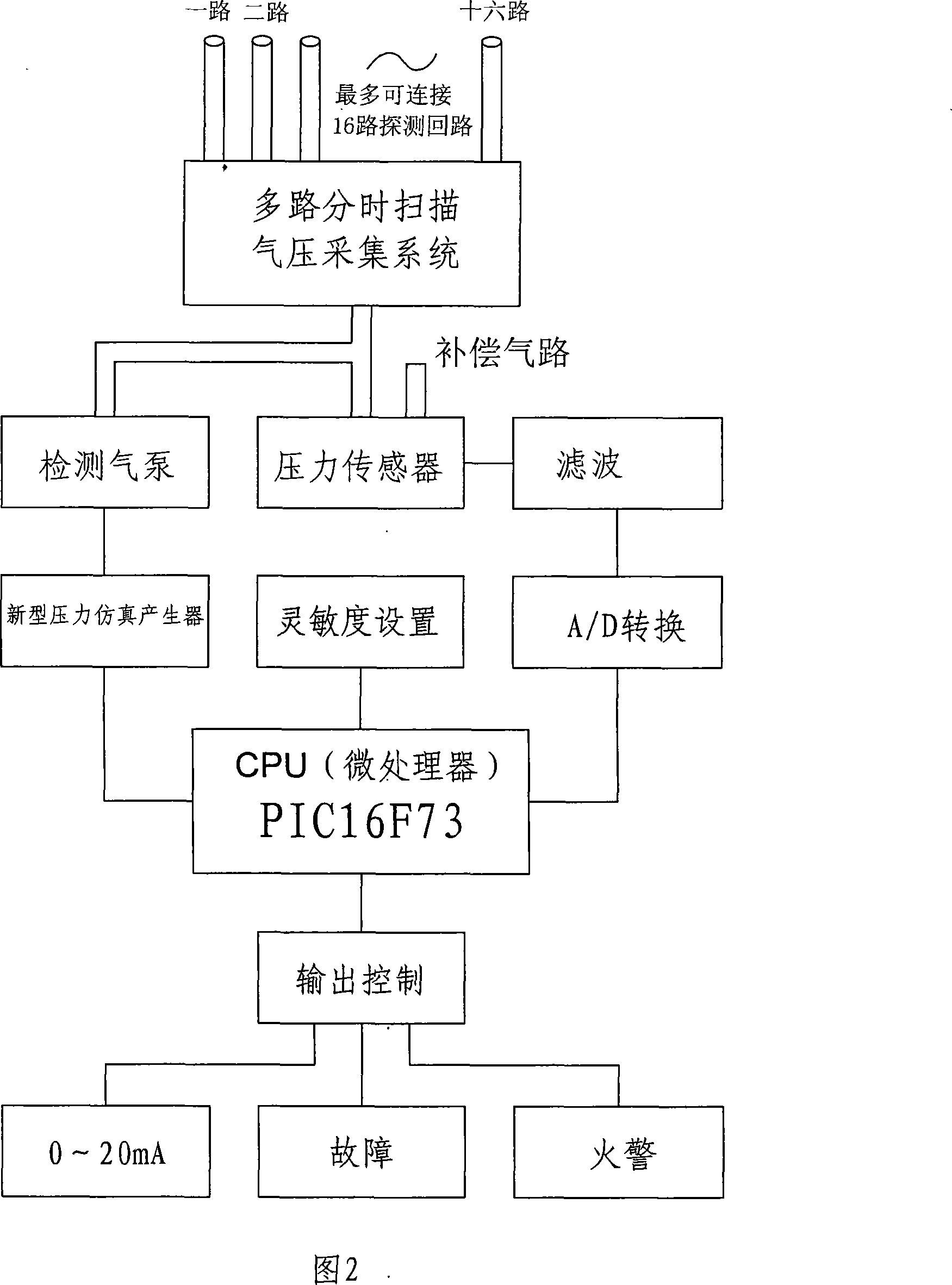

[0020] The present invention mainly consists of an end sealing cap 1, a detection tube 2, a screw connector 3, an air intake pipe joint 4, a high-tightness miniature solenoid valve 5 (hereinafter referred to as a solenoid valve), a box body 6, a joint 7, and a linear stepping micromotor 8 , pressure simulation generator 9, metal gas pump 10, inlet and outlet connectors 11, first circuit 12, CPU 13, circuit board 14, third circuit 15, multi-channel signal output terminal 16, second circuit 17, pressure sensor 18, reference chamber 19. Composed of multi-channel time-sharing scanning air pressure acquisition system 20, mounting plate 21, header block 22, auxiliary pipeline 23, etc.

[0021] As shown in Figure 1: the invention includes sensitive components, a novel multi-channel time-sharing scanning air pressure automatic monitoring system, an electronic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com