Set technique for extracting cadmium from waste and old nickel-cadmium battery, and producing ferro-nickel alloy

A technology of nickel-cadmium battery and nickel-iron alloy, which is applied in the complete process of producing nickel-iron alloy and the field of extracting cadmium, which can solve the problems of poor operability, low purity of recovered metal, and low recovery rate, and achieve no secondary pollution and considerable economic benefits , the effect of good social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

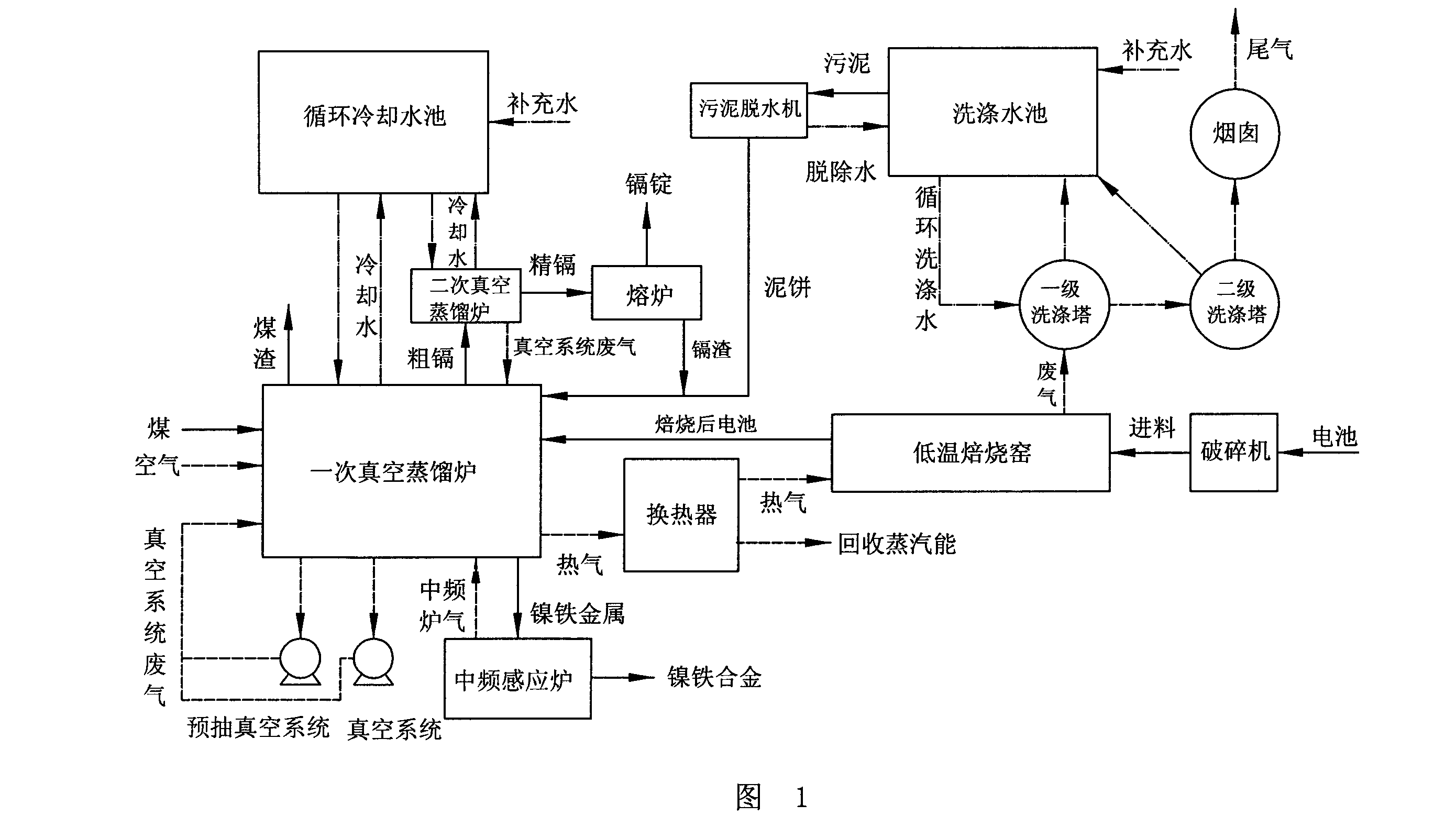

Image

Examples

Embodiment 1

[0018] (1) Use a scissor crusher to crush waste nickel-cadmium batteries, and keep more than 80% of the outlet particle size at 5mm.

[0019] (2) Fill the crushed nickel-cadmium batteries into a low-temperature roasting kiln for roasting, operate intermittently, and the roasting time is 7-8 hours. The inlet temperature of the heating gas is 400°C, and the outlet temperature is 200°C. As the operation progresses, the outlet temperature will increase, but it will not affect the drying and carbonization effects.

[0020] h 2 o (l) →H 2 o (g)

[0021] Organic matter → C+H 2 o (g) + other substances

[0022] (3) Mix the calcined battery and carbon powder evenly according to the mass ratio of 100:1, carry out a vacuum distillation, keep the calcination temperature at 900-1000°C, the vacuum degree at 100Pa, and the distillation time at 7-8h. Cadmium vapor is condensed with water. The furnace uses coal as fuel, and the design temperature is 1200°C.

[0023...

Embodiment 2

[0033] Other conditions are constant, change the crushing mode in (1) of embodiment 1 into the licker-in roller crusher and change the vacuum degree of vacuum distillation into 80Pa, the final cadmium recovery rate is 99.5%, the cadmium precision is 99.9%, and the nickel recovery rate is 99.5%. 100%, iron and nickel account for 91% in nickel-iron alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com