Refrigerating method of high-capacity optical fiber laser

A fiber laser and refrigeration method technology, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of unfavorable cooling liquid heat, small contact area between metal and cooling liquid, fiber structure damage, etc., to ensure continuous stability. The effect of running, lowering the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

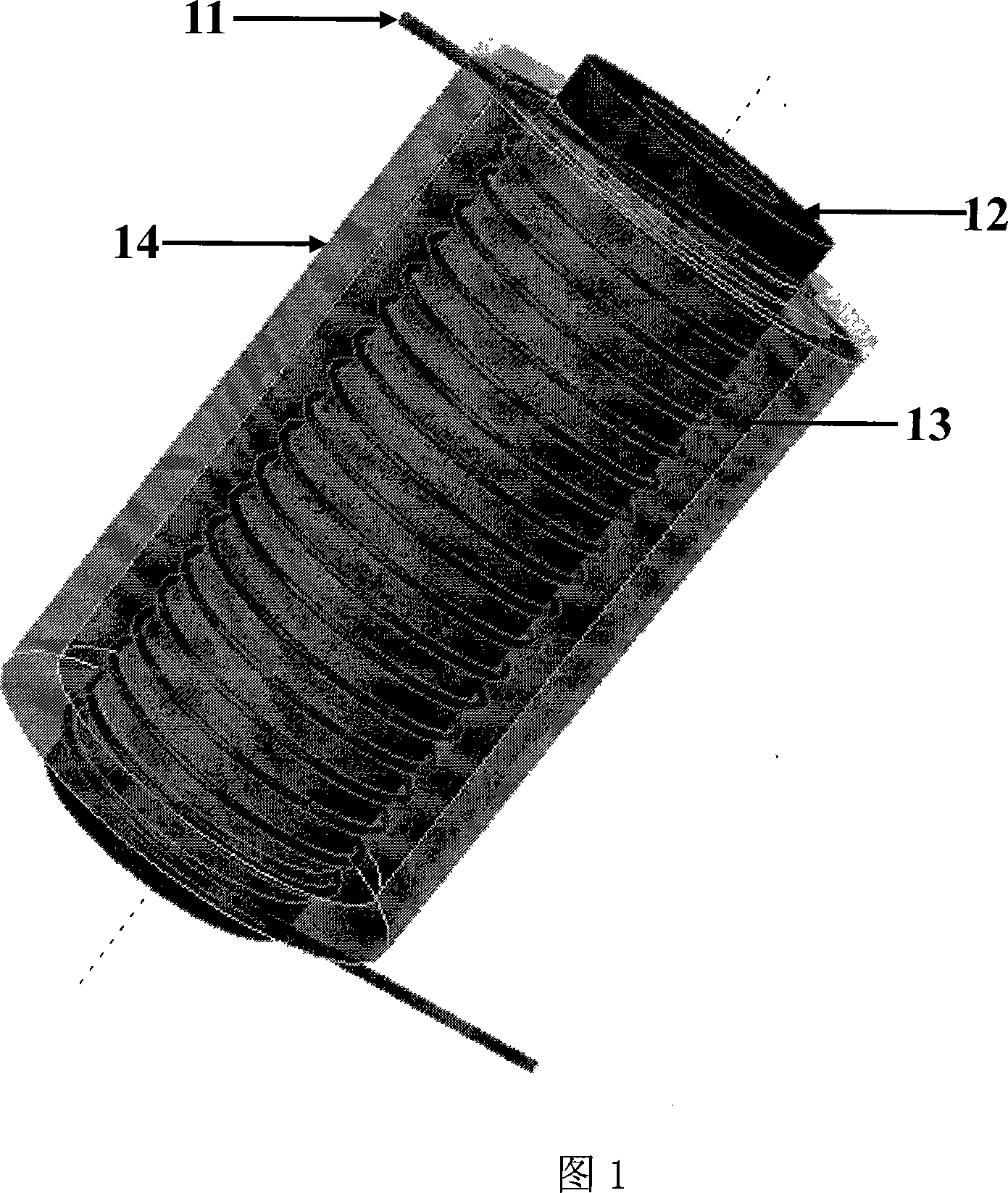

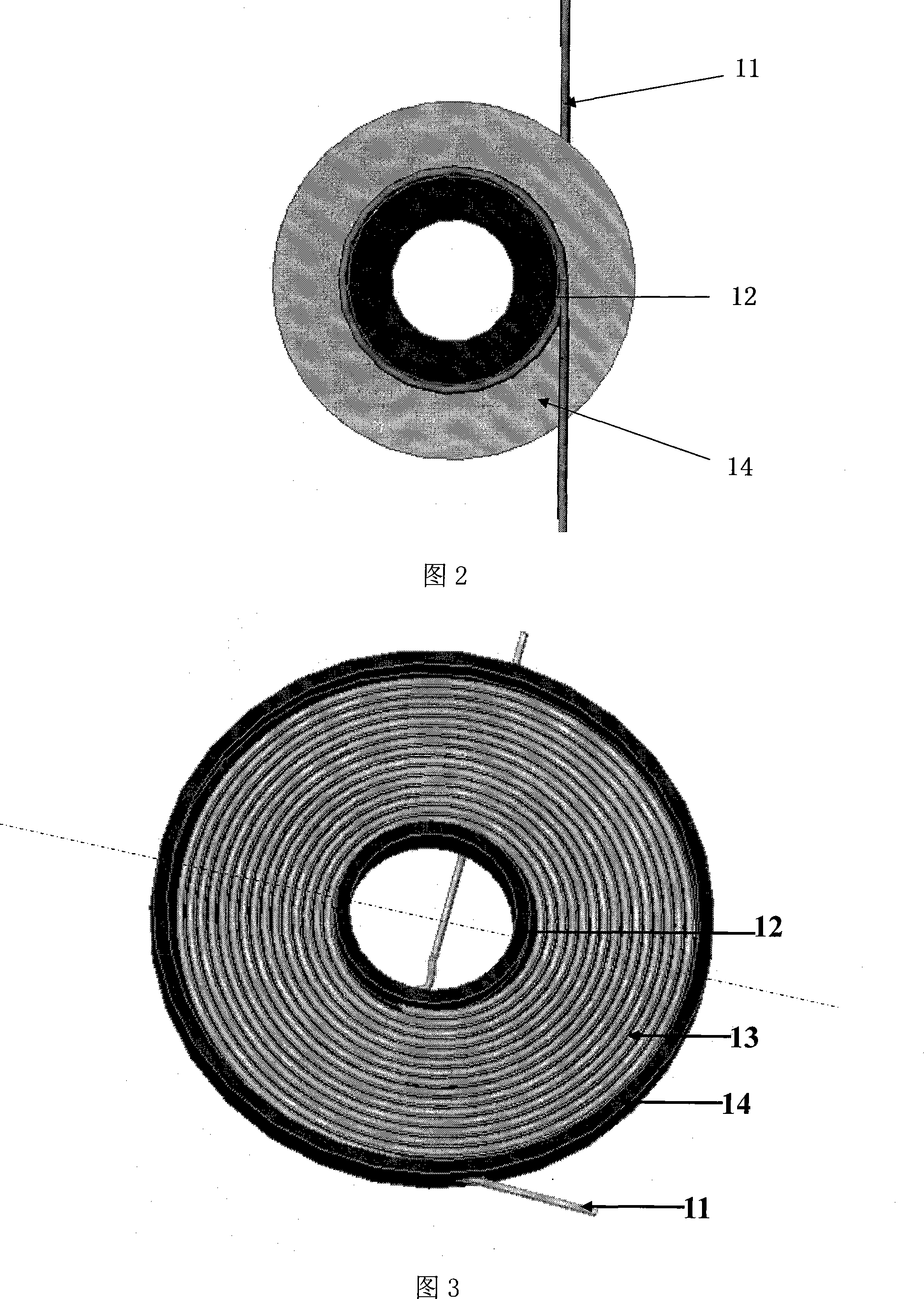

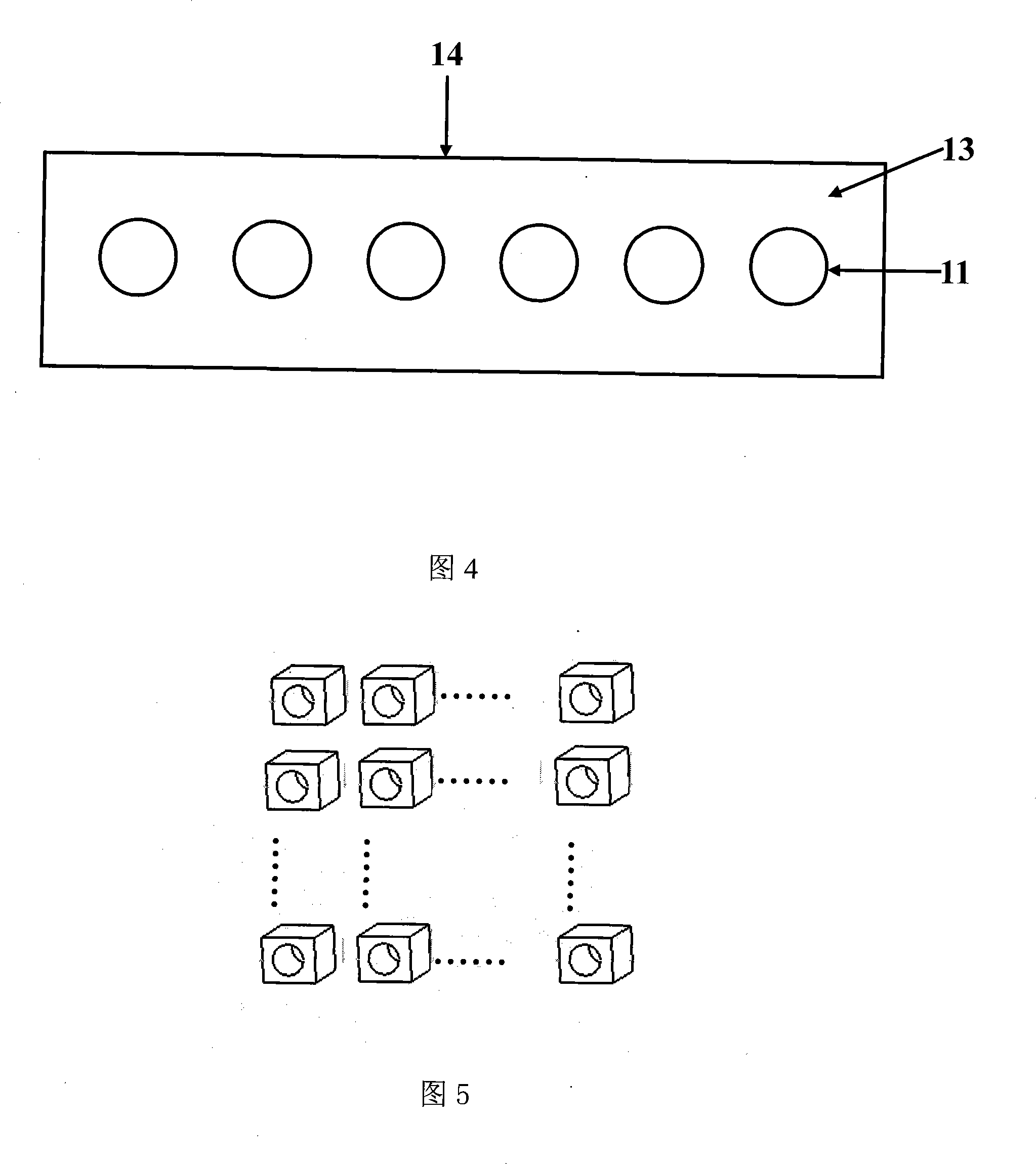

[0020] Fig. 1 is a structural diagram of the refrigeration method for a single high-power fiber laser of the present invention. It can be seen from the figure that the specific implementation structure of the refrigeration method for a single high-power fiber laser of the present invention is that the fiber laser 11 is wound on a metal tube 12 in a single layer and placed on Inside the metal sleeve 14 with coolant channels, the space between the fiber laser 11 and the metal sleeve 14 is filled with emulsion liquid or solid powder 13 . Both the inside of the metal pipe 12 and the cooling liquid channel adopt the flowing cooling liquid to take away the heat in time. Fig. 2 is a structural top view of the refrigeration method for a single high-power fiber laser of the present invention.

[0021] The cooling liquid may be cooling water or other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com