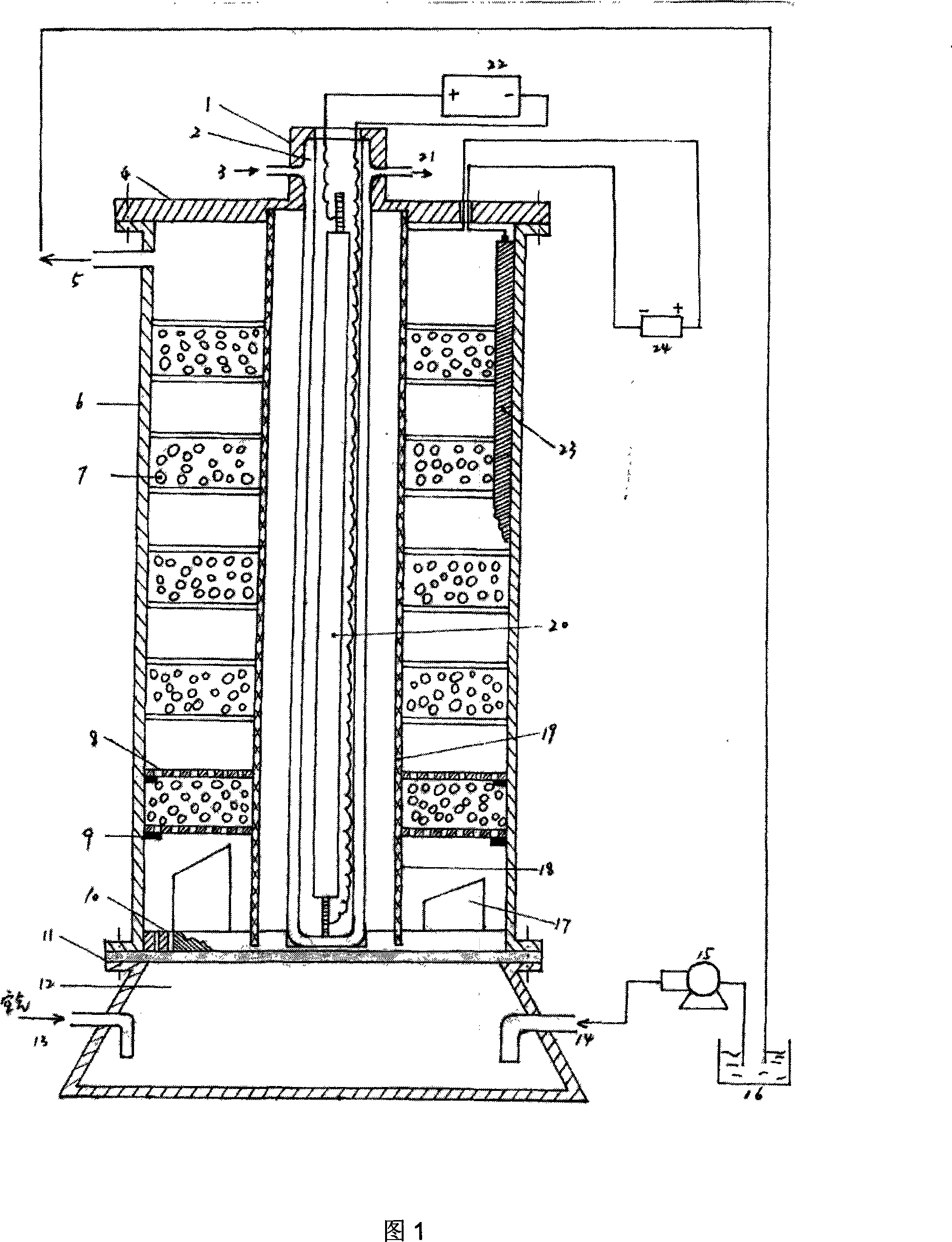

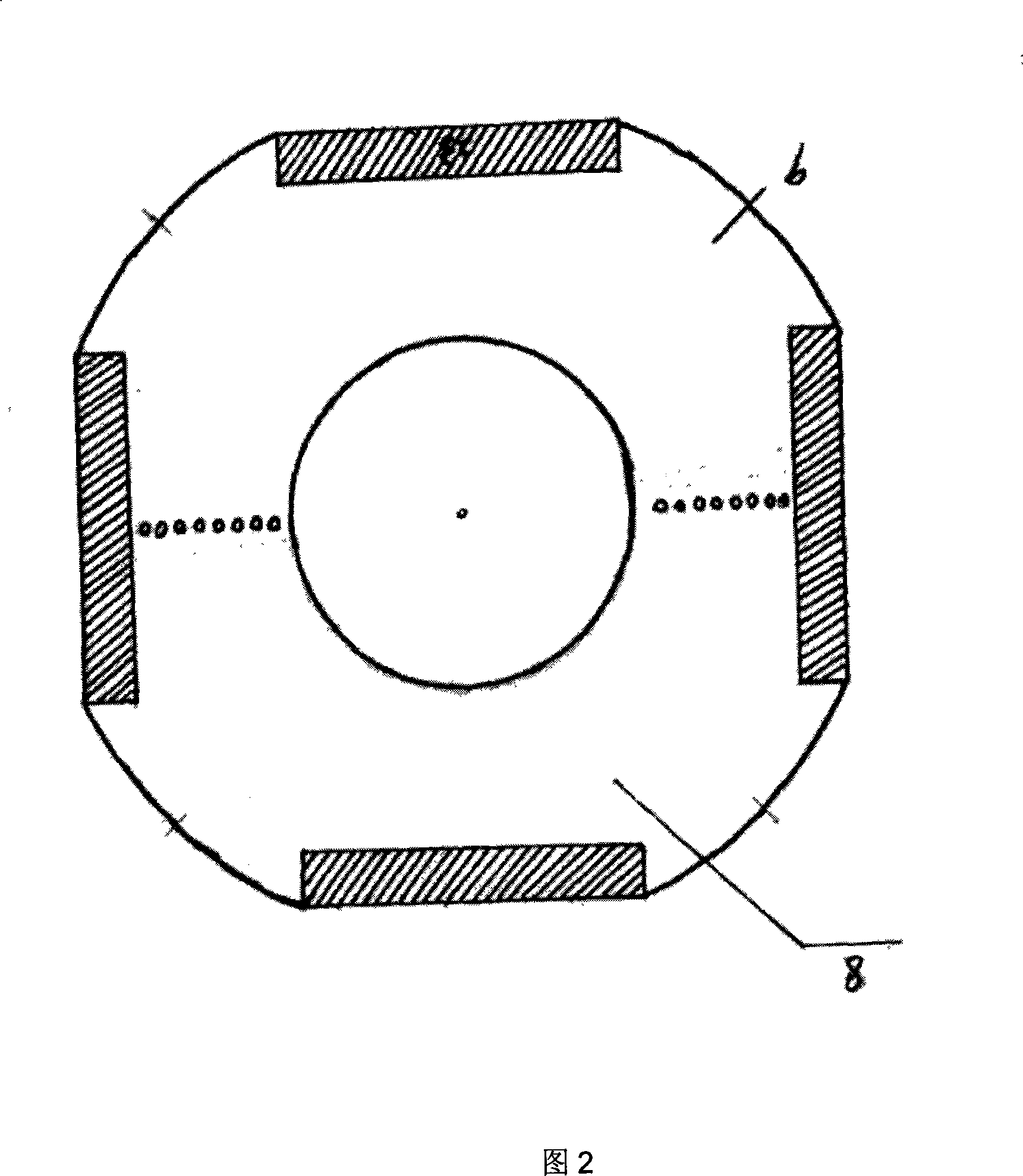

Fixed bed inhomogeneous three dimensional electrode photo electrocatalysis reactor

A technology of photoelectric catalysis and three-dimensional electrodes, which is applied in the fields of chemical instruments and methods, chemical/physical processes, oxidized water/sewage treatment, etc., can solve problems such as technology urgently needs to be upgraded, achieve organic coordination of reaction system, save cost, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

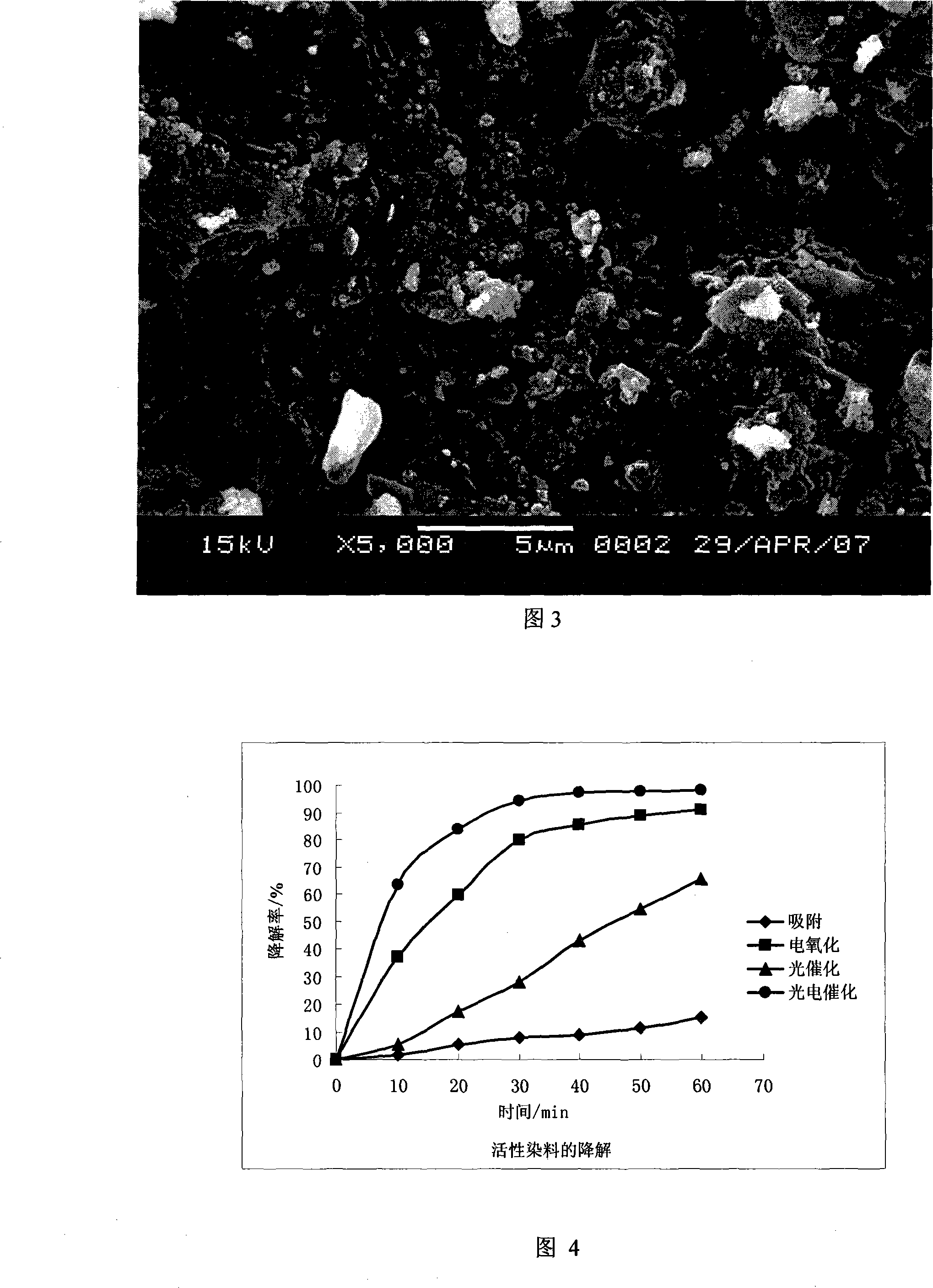

[0042] Process the Levafix Red of 200mg / L with the present invention's continuous cycle multi-layer spaced fixed bed heterogeneous three-dimensional electrode photocatalytic reactor, the active dye dye simulated waste liquid of pH value 6.27, at 15V voltage, 125W ultraviolet light source, load TiO Activated carbon The particle size of the particles is 3mm, the air flow rate is 0.3m3 / h, and under the condition of no electrolyte, the removal rate of the active dye is 98.25% when the photocatalytic reaction is 60min, which is higher than the 65.52% and 65.52% only in the photocatalytic and electrochemical oxidation 90.98% are high.

Embodiment 2

[0044] Using the present invention's continuous cycle multi-layer spaced fixed-bed heterogeneous three-dimensional electrode photocatalytic reactor to process 200mg / L Yimanlen polyester Red HSF 300, disperse dye simulated waste liquid with a pH value of 6.8, at 15V voltage, 125W ultraviolet light source, The particle size of the loaded TiO2 activated carbon particles is 5mm, the air flow rate is 0.3m3 / h, and under the condition of no electrolyte, the removal rate of the active dye is 95.46% when the photocatalytic reaction is 60min, which is higher than that only in the photocatalytic and electrochemical oxidation. 29.41% and 90.61% are both high.

Embodiment 3

[0046] Process the Levafix Red of 200mg / L with the present invention's continuous cycle multi-layer spaced fixed bed heterogeneous three-dimensional electrode photocatalytic reactor, the active dye dye simulated waste liquid of pH value 6.27, at 15V voltage, 125W ultraviolet light source, load TiO Activated carbon The particle size of the particles is 3mm, the air flow rate is 0.3m3 / h, and the electrolyte NaCl2g / L is added, the removal rate of the active dye is 97.74% when the photoelectric catalytic reaction takes 24 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com