Preparation method of benzene sulfochloride substituted carbon nano-tube and grafting modification method initiated thereby

A technology of carbon nanotubes and benzenesulfonyl chloride, which is applied in the field of preparation of carbon nanotubes substituted by benzenesulfonyl chloride and the grafting modification caused by it, can solve problems such as technical barriers and insufficiencies of covalent connection, and achieve improved controllability Sexuality, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further described in conjunction with specific embodiments.

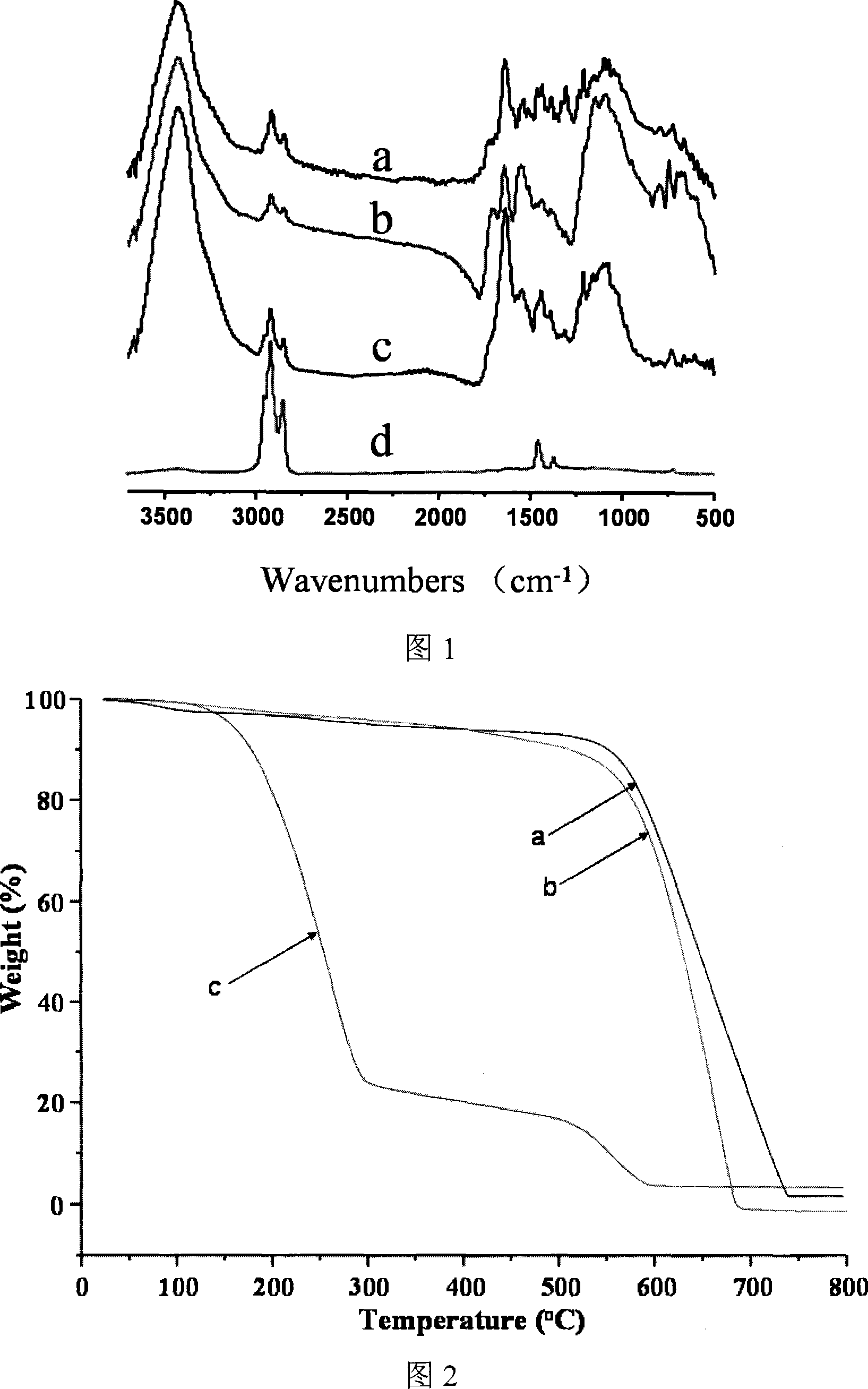

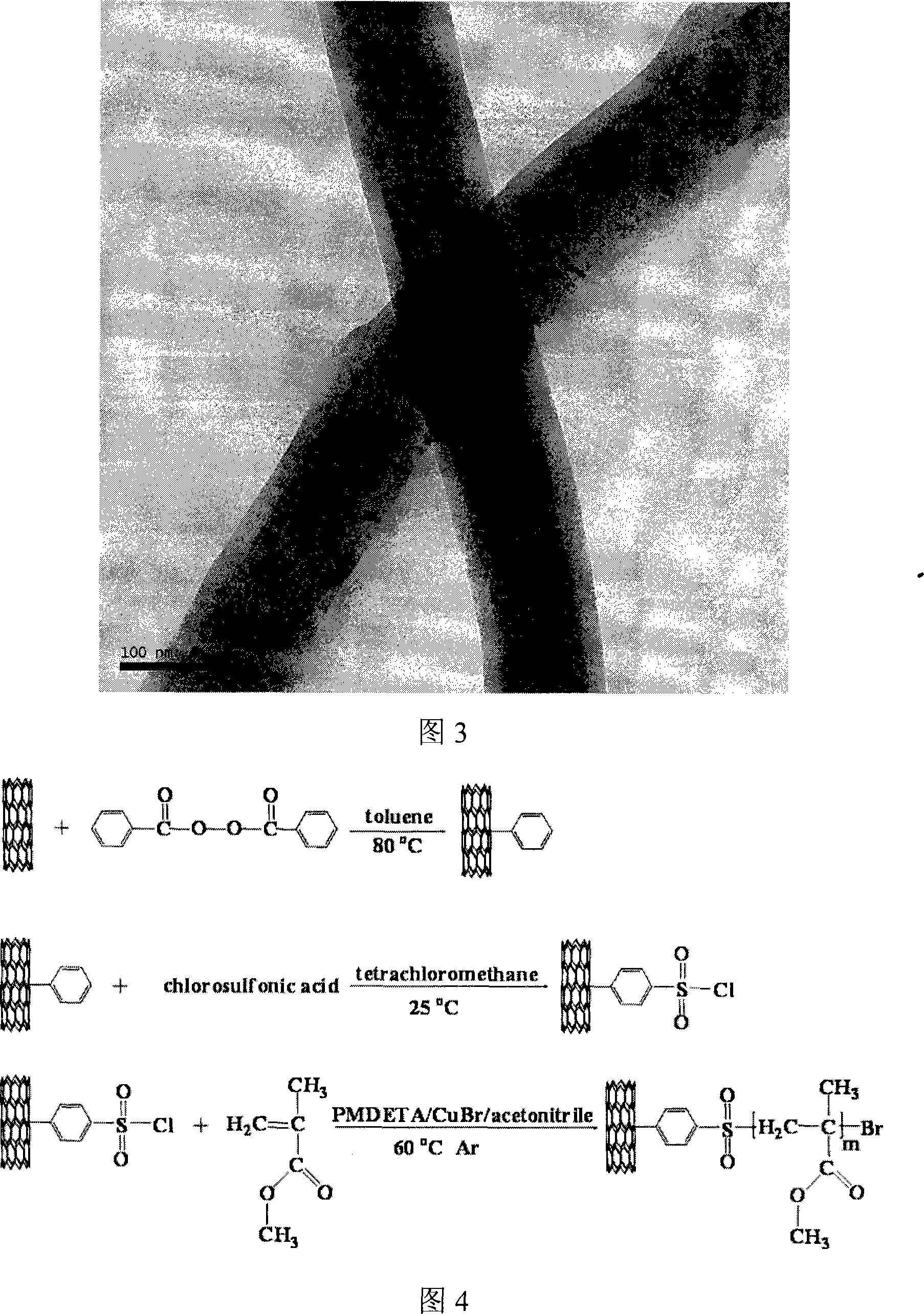

[0021] 1. Preparation of carbon tubes substituted by benzenesulfonyl chloride

[0022] Purification of carbon nanotubes:

[0023]First, 5.0 g of carbon nanotubes was added into a 1000 mL round bottom flask filled with 500 mL of acid, and the remaining catalyst particles were removed by ultrasonication at room temperature for 6 hours. Subsequently, the mixture was diluted with distilled water and filtered through a 0.45 μm pore size sand filter until no residual acid remained, and the obtained solid was completely dehydrated in a vacuum oven. Secondly, based on the different oxidation properties of carbon nanotubes and non-carbon nanotube impurities (bucky onion, spherical fullerene and amorphous carbon), the impurities can be removed by oxidation at 200-500°C for 2 hours under the action of an oxidizing atmosphere. Finally, in order to remove the carboxyl groups on the surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com