Solid imaging element and manufacturing method thereof

A technology of image sensor and manufacturing method, which is applied in the direction of semiconductor devices, image communication, electric solid devices, etc., can solve the problems of small opening area, poor chip usage efficiency, increased cost of area, etc., and achieve the effect of improving optoelectronics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] Embodiments of the present invention will be described below with reference to the accompanying drawings.

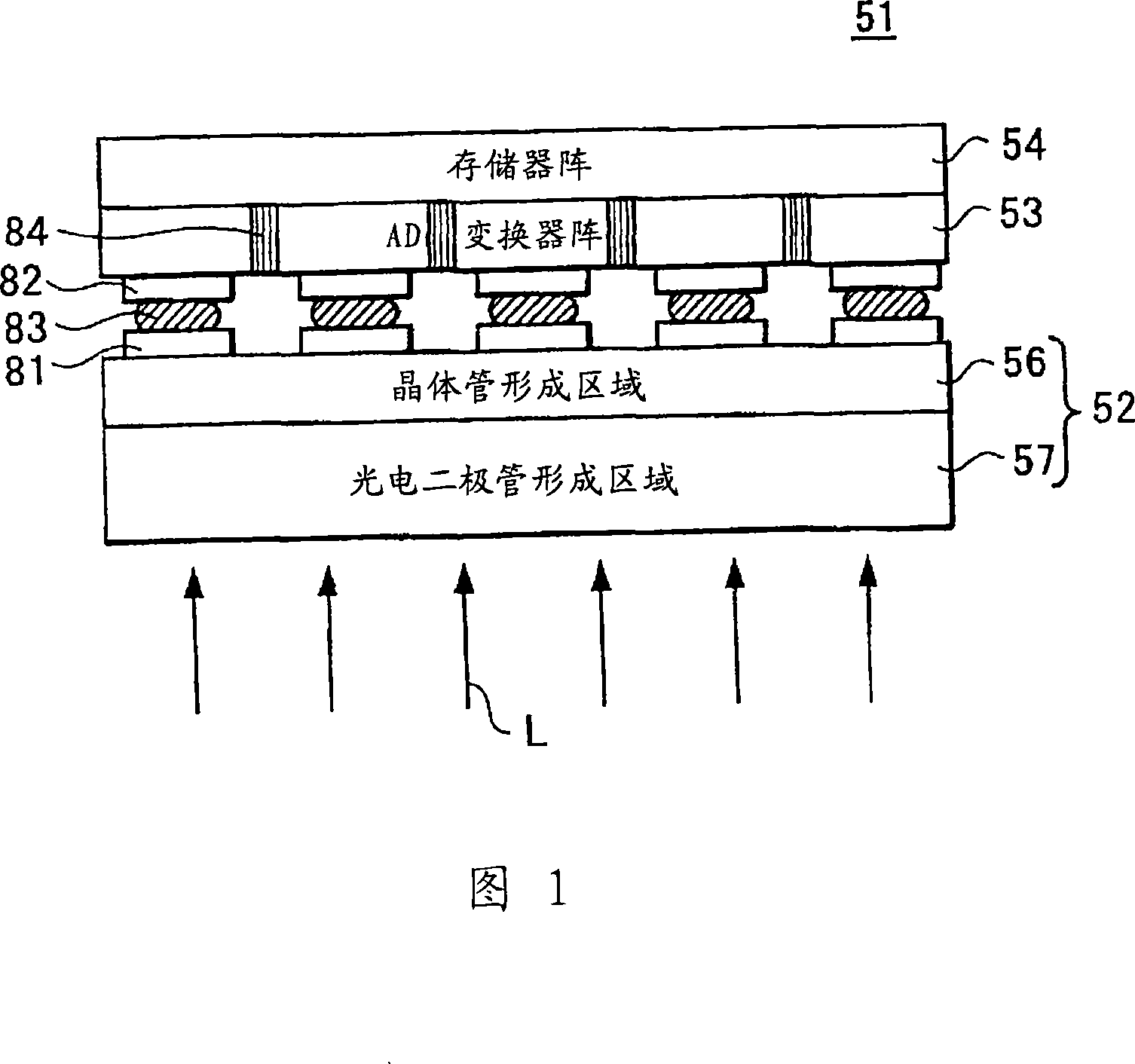

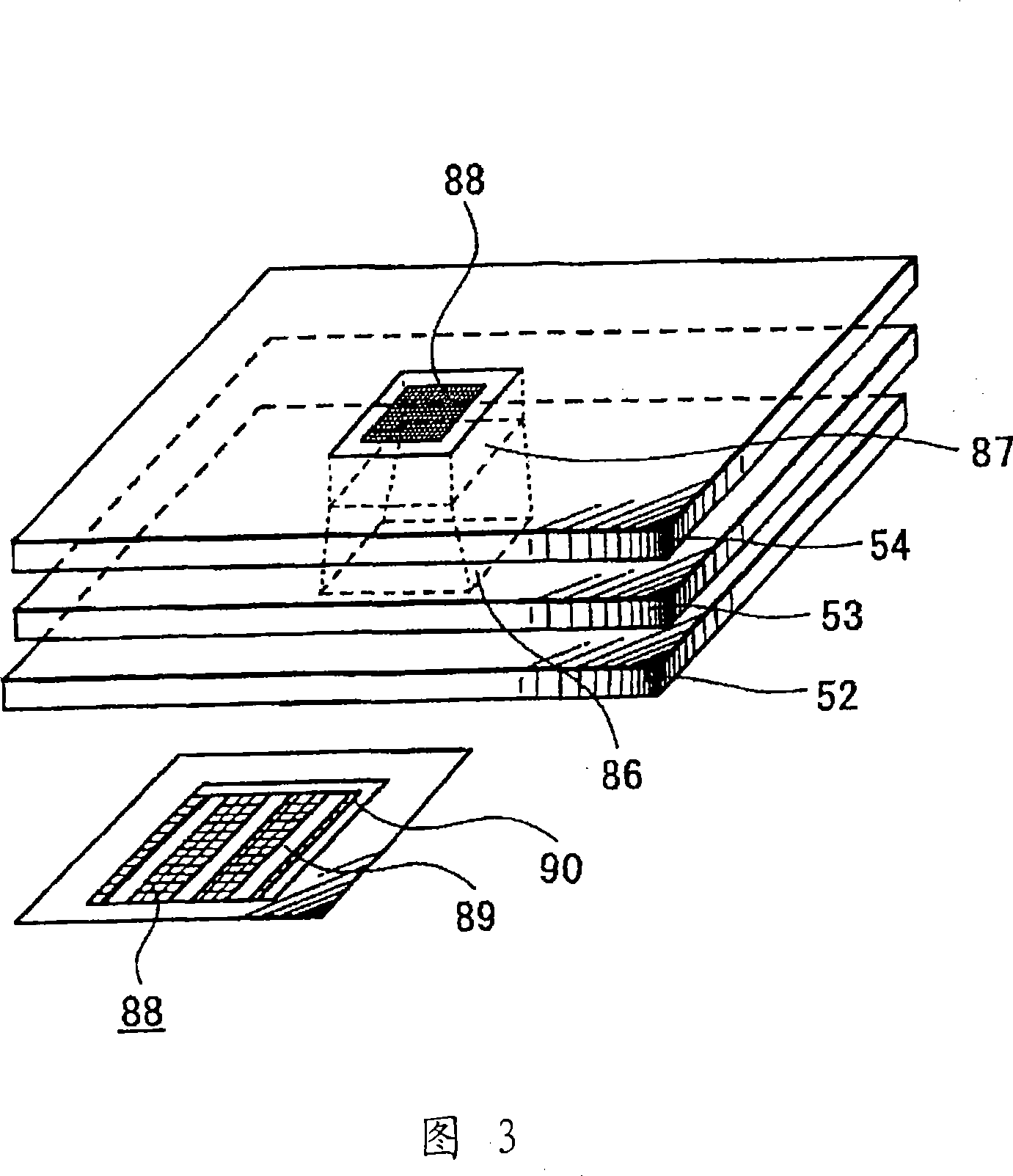

[0090] FIG. 1 shows a schematic configuration of a first embodiment of a semiconductor image sensor module of the present invention. The semiconductor image sensor module 51 according to the embodiment of the present invention is laminated with: a first semiconductor chip 52 including an image sensor in which a plurality of pixels are regularly arranged and each pixel is composed of a photodiode and a transistor serving as a photoelectric conversion element; a second semiconductor chip 53, which includes an analog-to-digital converter array (so-called analog-to-digital conversion circuit) composed of a plurality of analog-to-digital converters; and a third semiconductor chip 54, which includes a memory element array including at least an encoder and a sense amplifier .

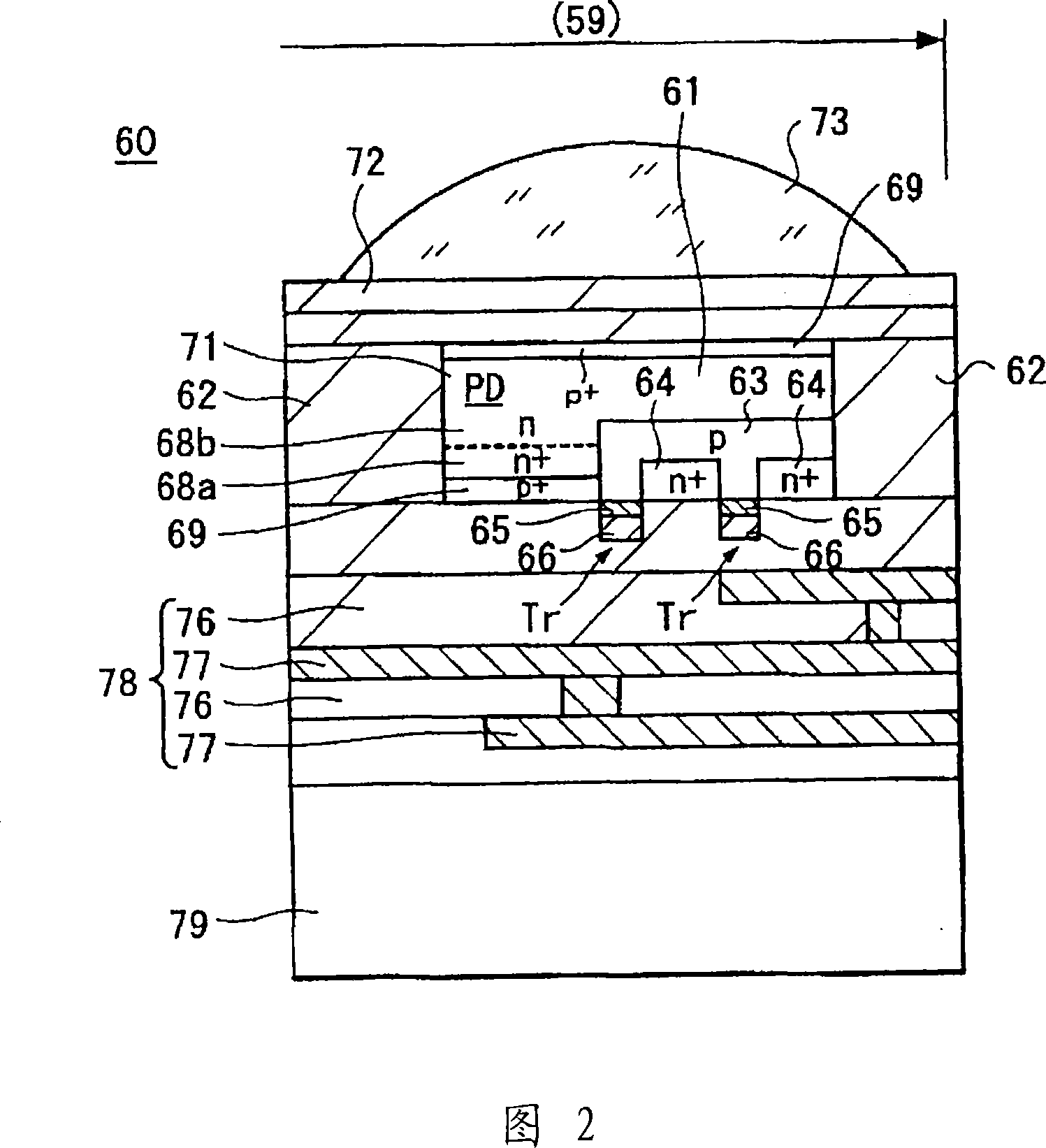

[0091] In the image sensor of the first semiconductor chip 52, in this example, a transistor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com