Ionic liquid formed by dimethylamide and thiocyanate and its preparation method and application

A technology of dimethylamide and dimethylformamide, applied in the field of ionic liquids, can solve the problems of high price and high price, and achieve the effects of low cost, easy preparation, and suitable for large-scale industrial production and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 Extraction

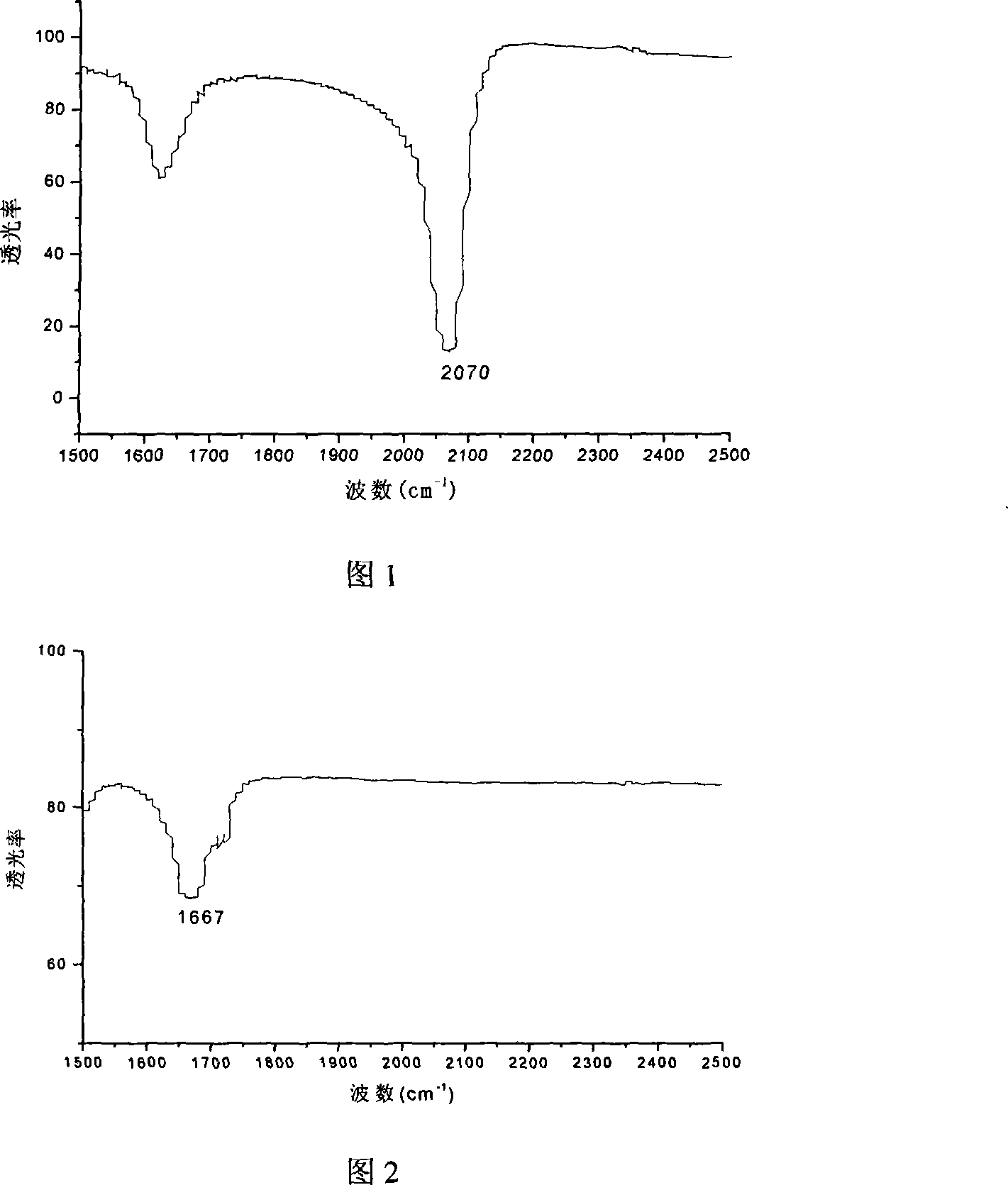

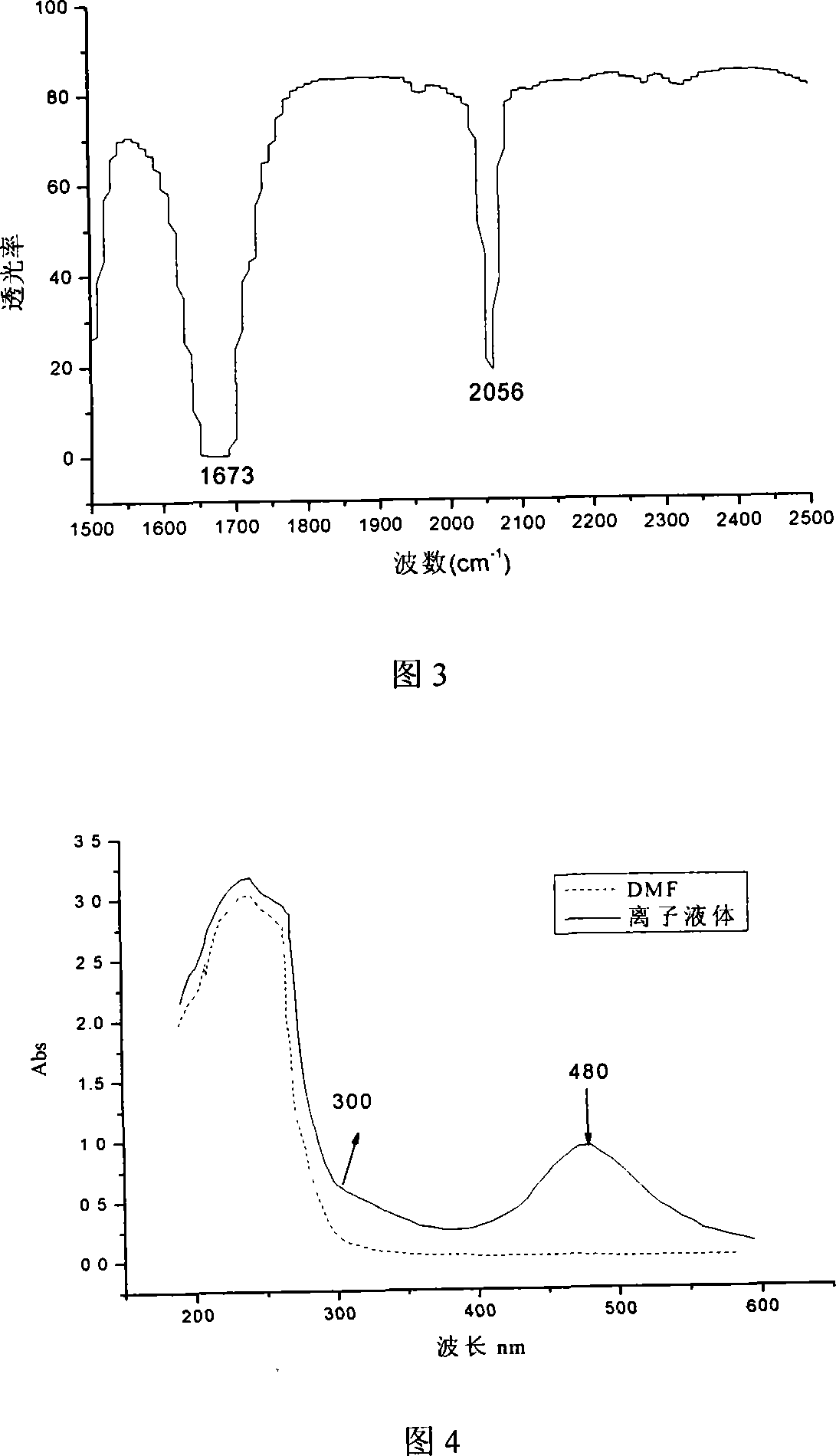

[0023] Weigh 10g of potassium thiocyanate and dissolve it in 100ml of N,N-dimethylformamide, stir well until it is completely dissolved, let it stand at room temperature for 8h, the solution turns pink to obtain an ionic liquid. Add it to extract and separate the benzene-n-heptane system. When the volume ratio of benzene and n-heptane in the raw material liquid is 1:1, and the volume ratio of ionic liquid and raw material is 1:1, the distribution coefficient of n-heptane after extraction is 10.17 , The distribution coefficient of benzene is 1.22, and the selectivity coefficient reaches 8.32.

Embodiment 2

[0024] Example 2 Extraction

[0025] Weigh 10g of ammonium thiocyanate and dissolve it in 100ml of N,N-dimethylformamide, stir well until it is completely dissolved, let it stand at room temperature for 4h, the solution turns pink to obtain an ionic liquid. It is added to extract and separate the benzene-cyclohexane system. When the volume ratio of benzene and cyclohexane in the raw material liquid is 1: 1, and the volume ratio of ionic liquid and raw material is 1: 1, the distribution coefficient of cyclohexane after extraction is 2.97, the distribution coefficient of benzene is 0.94, and the selectivity coefficient is 3.16.

Embodiment 3

[0026] Embodiment 3 extractive distillation

[0027] Weigh 18g of potassium thiocyanate and dissolve it in 100ml of N,N-dimethylformamide, stir well until it is completely dissolved, leave it at room temperature for 6h, and the solution turns pink to obtain the target ionic liquid. The ionic liquid is added to the benzene-cyclohexane system as the separation agent required for extractive distillation, when the volume ratio of benzene and cyclohexane in the raw material liquid is 1:1, and the volume ratio of the ionic liquid to the raw material is 0.3:1 , extraction and rectification separation of benzene and cyclohexane, the relative volatility between the components increased to 2.17.

PUM

| Property | Measurement | Unit |

|---|---|---|

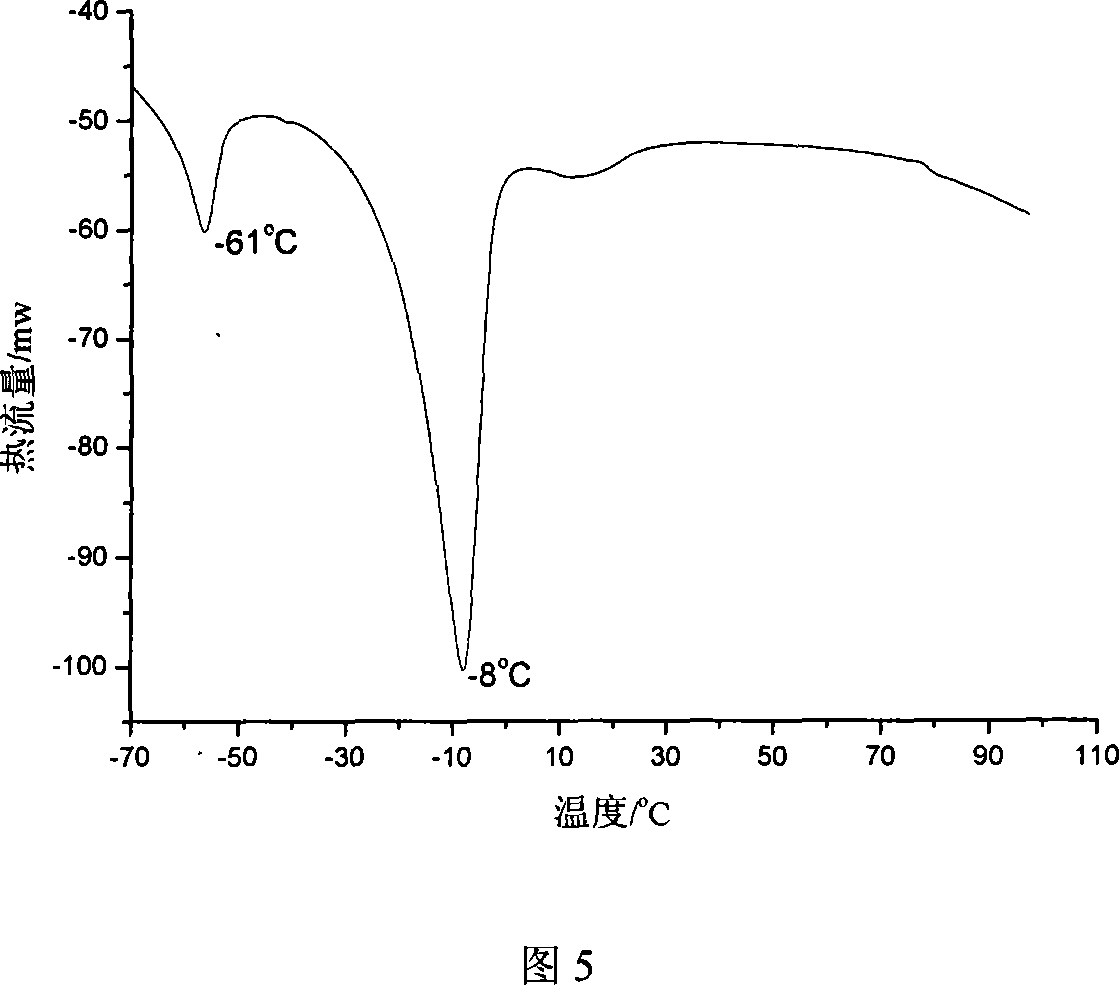

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com