Method for extracting and purifying two kinds of taxane compound from yew branches and leaves

A technology of yew branches and leaves and acetyl-paclitaxel, which is applied in the direction of organic chemistry, can solve the problems of polluting the environment and wasting plant resources, achieve high-efficiency utilization, realize industrial production, and the effect of simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

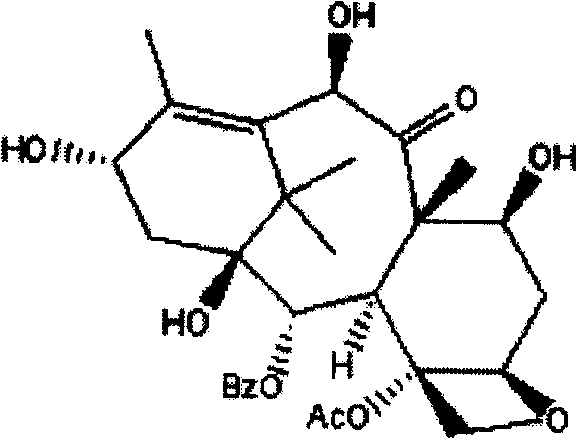

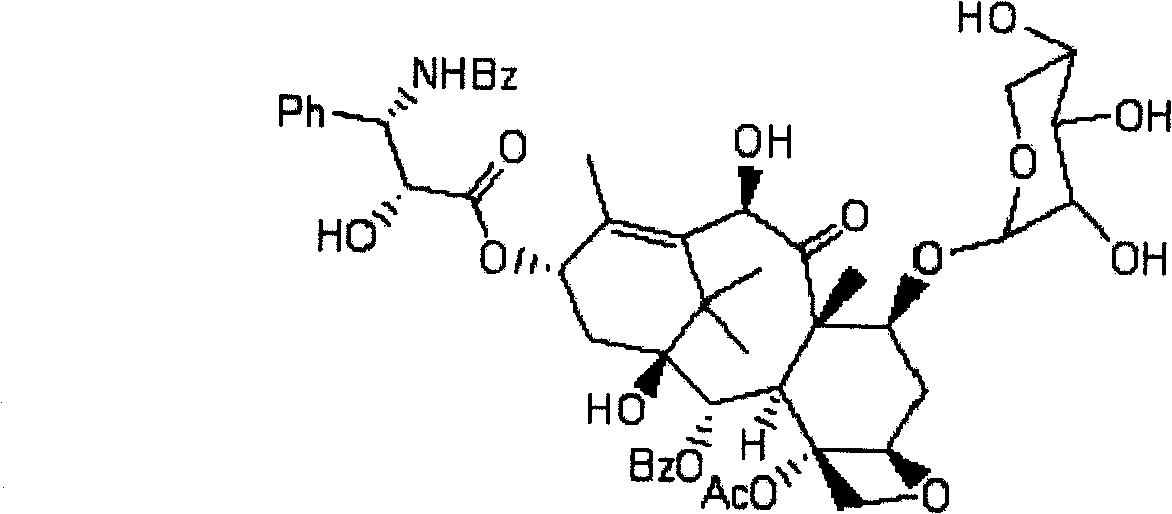

Image

Examples

Embodiment 1

[0021] Weigh 200g of southern yew branches and leaves, dry and pulverize, add 2000mL of water for negative pressure cavitation extraction, filter after 30min, and add the filtrate to a glass column equipped with 35g of AB-8 resin for dynamic adsorption. The loading solution is 15BV, The concentrations of 10-deacetylbaccatin III and 7-xylosyl-10-deacetylpaclitaxel in the sample solution were: 0.0657mg / mL and 0.1681mg / mL, the flow rate was 1mL / min, and the temperature was 35 ℃, using gradient elution method: 3BV of 30% ethanol was eluted to remove impurities, and then 6BV was eluted with 80% ethanol, the fractions were collected and concentrated to dryness. The content of -xylosyl-10-deacetyl paclitaxel was increased from 0.2% and 0.053% to 1.69% and 3.34%, respectively, which was increased by 8.54 times and 62.43 times respectively. After the resin was enriched, the sample was purified by 300-400 mesh medium-pressure silica gel column chromatography. The silica gel used was 40 ...

Embodiment 2

[0023]Weigh 200g of Taxus chinensis branches and leaves, dry and pulverize them, add 2000mL of water for negative pressure cavitation extraction, filter after 30min, add the filtrate to a glass column filled with 35g of AB-8 resin, and perform dynamic adsorption. The loading solution is 15BV. The contents of 10-deacetylbaccatin III and 7-xylosyl-10-deacetyl paclitaxel in the sample solution were 0.0519mg / mL and 0.1673mg / mL respectively, the flow rate was 1mL / min, and the temperature was 35°C , using the method of gradient elution: 30% ethanol elution of 3BV to remove impurities, then 6BV 80% ethanol elution, collected fractions, concentrated to dryness, after resin enrichment, 10-deacetylbaccatin III and 7- The content of xylosyl-10-deacetyl paclitaxel increased from 0.16% and 0.049% to 1.57% and 3.46%, respectively, increasing 9.81 times and 70.61 times respectively. After the resin was enriched, the sample was purified by 300-400 mesh medium-pressure silica gel column chroma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com