Plant type environmental protection wall paper and manufacturing method thereof

A plant-based and plant-based technology, which is applied in the field of plant-based environmental protection wallpaper and its production, can solve the problems that environmental protection problems have not been effectively solved, the strength and service life cannot meet the requirements, and achieve low cost, reduced energy, and wide sources of raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

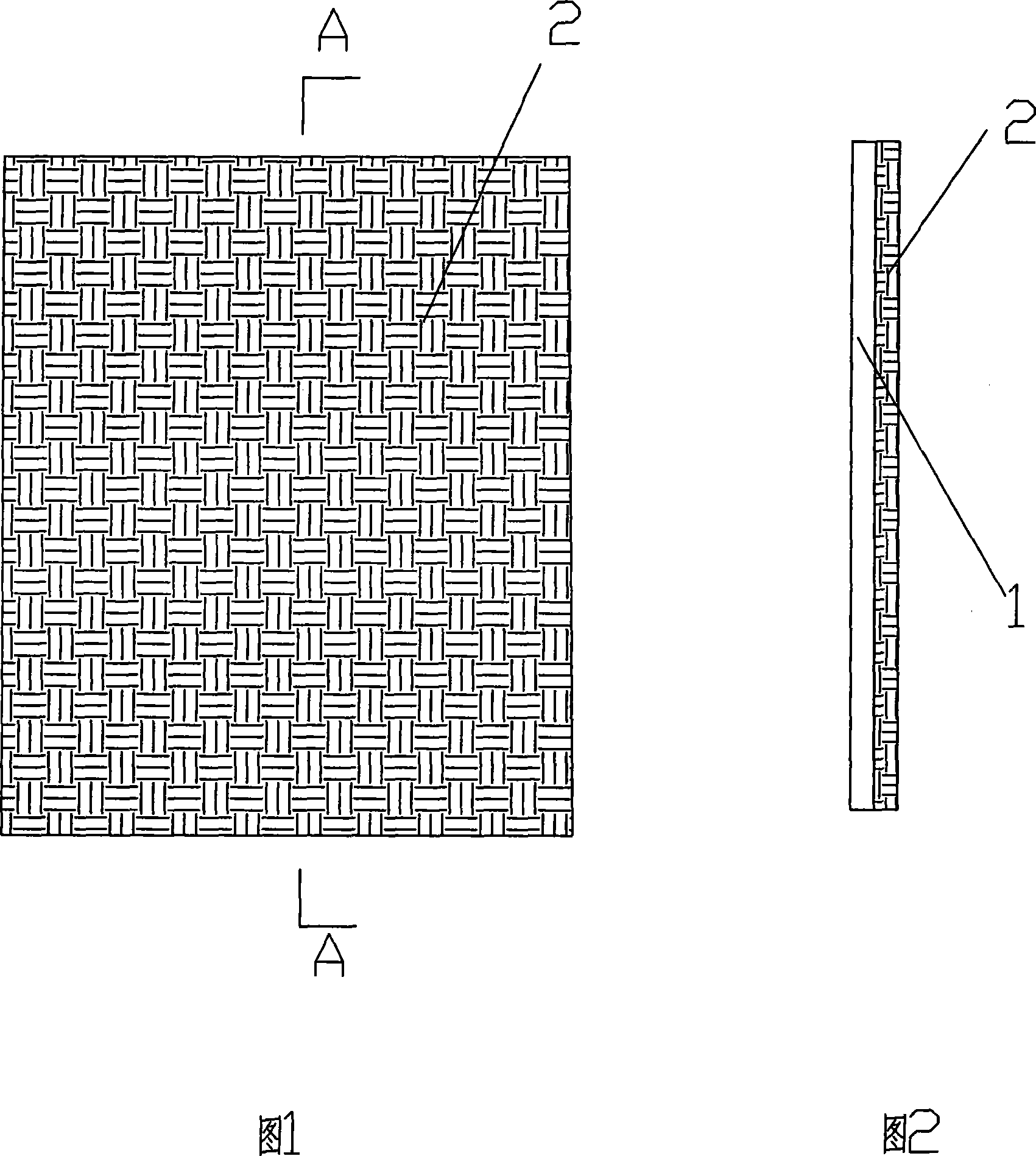

[0026] In this embodiment, the raw material of the plant layer is kudzu vine, and the material of the backing layer is cloth material.

[0027] (1) material selection: select qualified kudzu vines, and carry out 24 hours of softening, anti-corrosion and anti-insect treatment by drug water immersion;

[0028] (2) Raw materials for making and making: processing and making the required kudzu rattan;

[0029] (3) weaving: weaving plain plant layer, warp and weft are kudzu rattan;

[0030] (4) Dyeing: dyeing the woven plant layer according to the desired color;

[0031] (5) prepare glue: get 9.5 kilograms of water and adjust the wheat flour into paste, add 5 kilograms of natural liquid rubber of rubber tree, stir evenly, obtain glue;

[0032] (6) Thermocompression bonding: the woven kudzu plant layer is placed on the paper material backing layer coated with glue, and the thermocompression molding is carried out at a pressure of 1.2MPa and a temperature of 120° C. for 1.5 minutes;...

Embodiment 2

[0035] In this embodiment, the raw material of the plant layer is kudzu vine, and the material of the backing layer is paper material.

[0036] (1) material selection: select qualified kudzu vines, and carry out 48 hours of drug water soaking, softening, anti-corrosion and insect-proof treatment;

[0037] (2) Raw materials for making and making: processing and making the required kudzu rattan;

[0038] (3) weaving: weaving twill plant layer, warp and weft are kudzu rattan;

[0039] (4) Dyeing: dyeing the woven plant layer according to the desired color;

[0040] (5) prepare glue: get 9.5 kilograms of water and adjust the wheat flour into paste, add 5 kilograms of natural liquid rubber of rubber tree, stir evenly, obtain glue;

[0041] (6) Thermocompression bonding: the woven kudzu plant layer is placed on the paper material backing layer coated with glue, and the thermocompression molding is carried out for 1.5 minutes at a pressure of 1.0MPa and a temperature of 100°C;

[...

Embodiment 3

[0044] In this embodiment, the raw material of the plant layer is kudzu vine, and the material of the backing layer is paper material.

[0045] (1) material selection: select qualified kudzu vines, and carry out 72 hours of softening, anti-corrosion and anti-insect treatment by drug water immersion;

[0046] (2) Raw materials for making and making: processing and making the required kudzu rattan;

[0047] (3) weaving: weaving twill plant layer, warp and weft are kudzu rattan;

[0048] (4) Dyeing: dyeing the woven plant layer according to the desired color;

[0049] (5) prepare glue: get 9.5 kilograms of water and adjust the wheat flour into paste, add 5 kilograms of natural liquid rubber of rubber tree, stir evenly, obtain glue;

[0050] (6) Thermocompression bonding: place the kudzu vine plant layer that is woven and formed on the paper material backing layer coated with glue, and perform thermocompression molding at a pressure of 0.6MPa and a temperature of 80°C for 2 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com