Optical forceps based on ring -shaped multi- core optical fibre

A multi-core optical fiber and single-core optical fiber technology, applied in the field of optical tweezers, can solve the problems of unfavorable living micro-life research, small capture force, and elevated temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

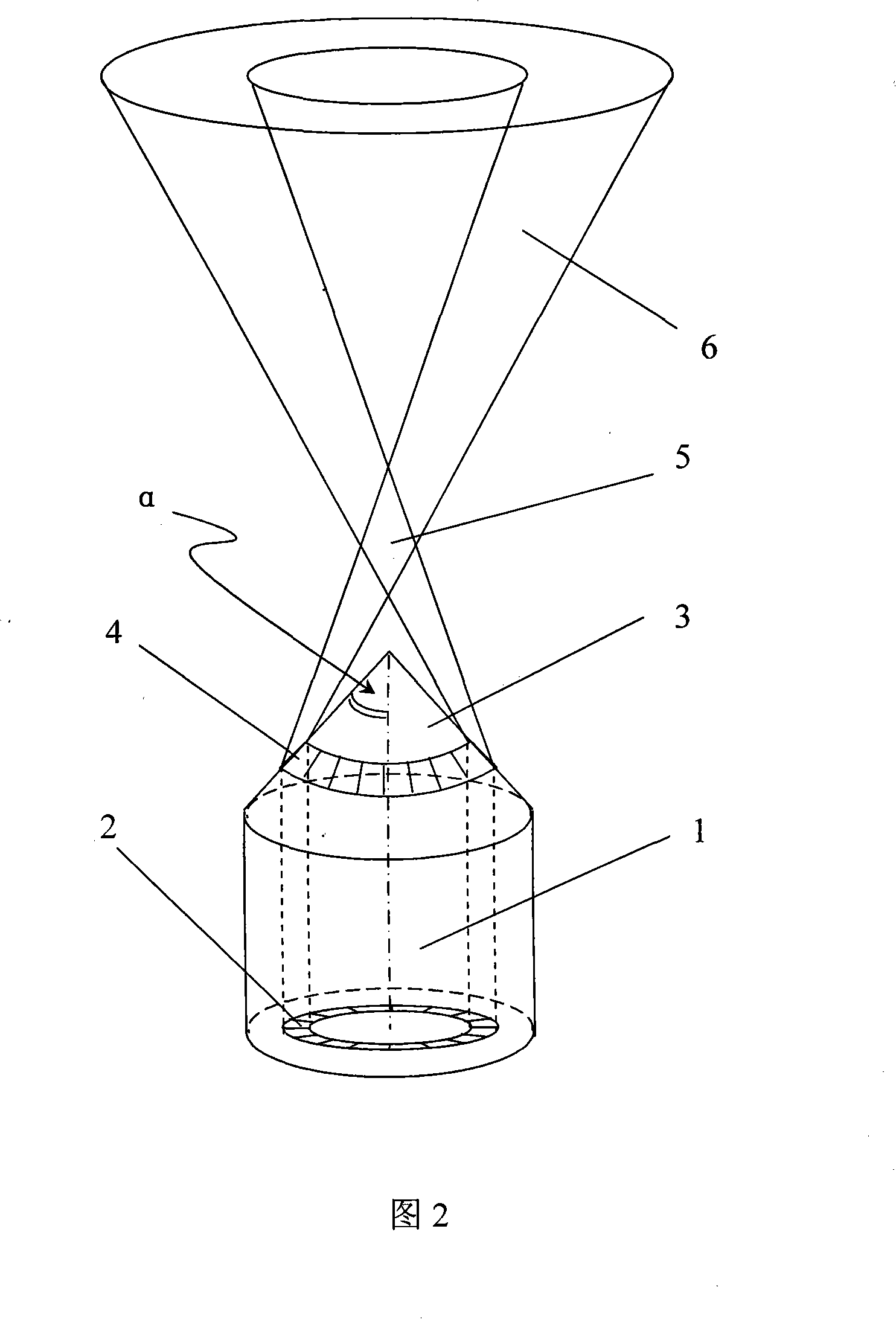

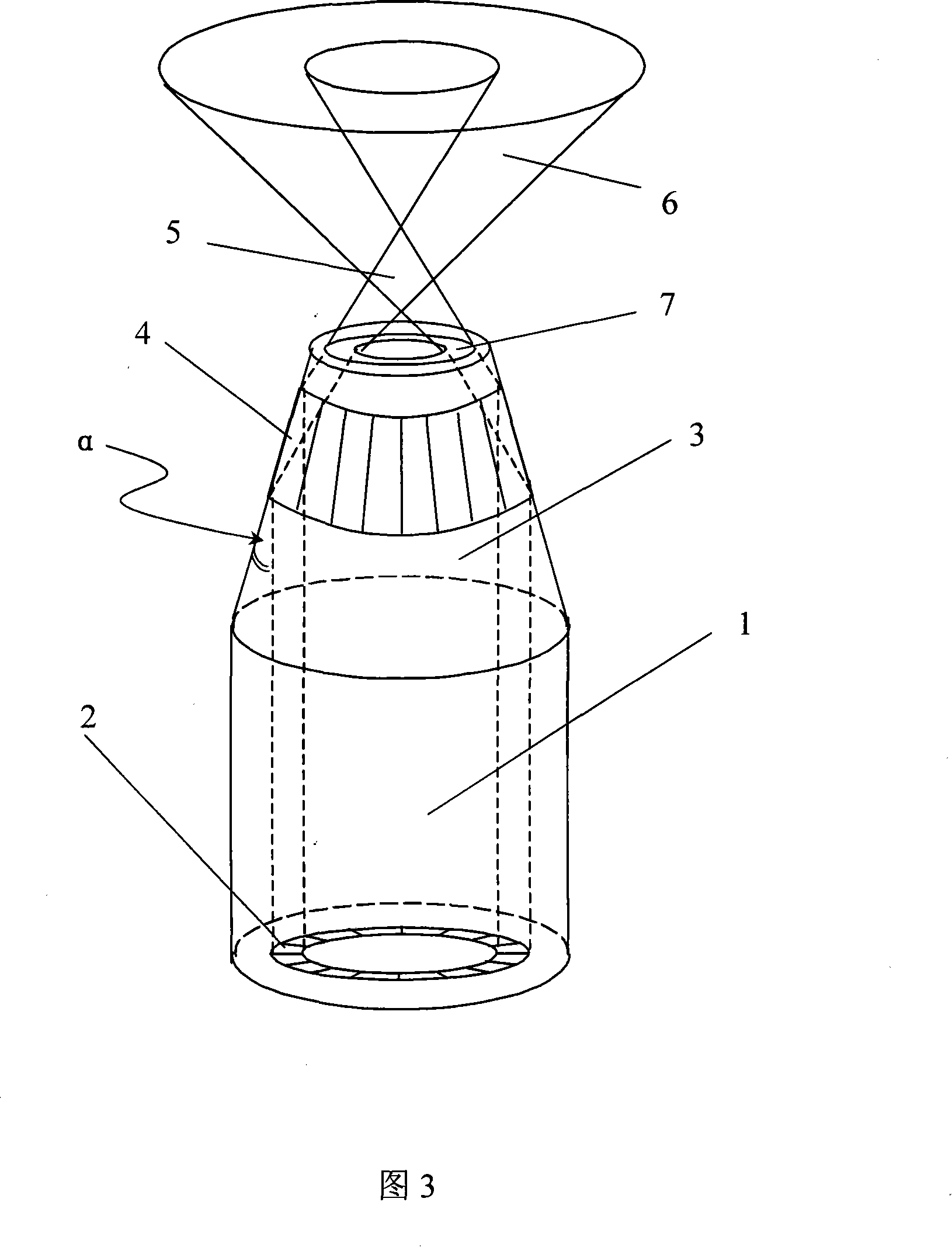

[0022] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0023] In conjunction with Fig. 2, the first embodiment of the present invention includes an optical fiber, and the optical fiber includes an optical fiber with an annular multi-core structure and a single-core optical fiber coupled and connected to the tail end of the three-core optical fiber, and the front end of the optical fiber with an annular multi-core structure passes through The method of grinding and processing the fiber end is made into a cone. The cone is formed by grinding the fiber end, and the conical half cone angle α is controlled at π / 2-arcsin(n liquid / n core )<α<π / 2. Its specific implementation process is as follows:

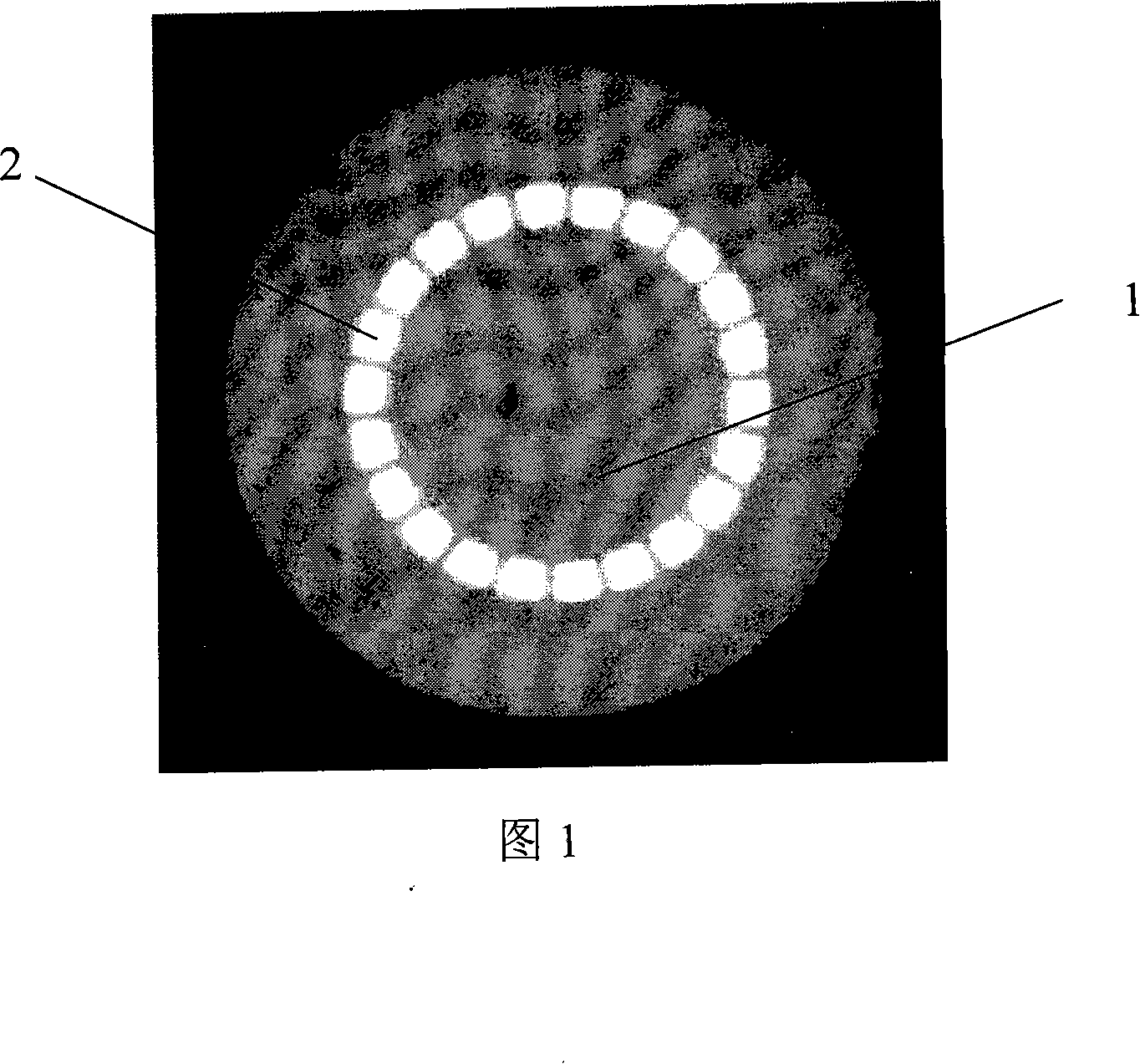

[0024] Step 1, cone grinding: take a section of annular multi-core optical fiber as shown in Figure 1, wherein 1 is an optical fiber with an annular multi-core structure; 2 is an optical fiber core in an annular distribution s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com