Cleaning treatment method of acid sewage storage tank discharging gas

A technology for acidic sewage and gas discharge, applied in the direction of heating water/sewage treatment, chemical instruments and methods, separation methods, etc., can solve the problems of high operating costs and complicated processes, and achieve the effect of low operating costs and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

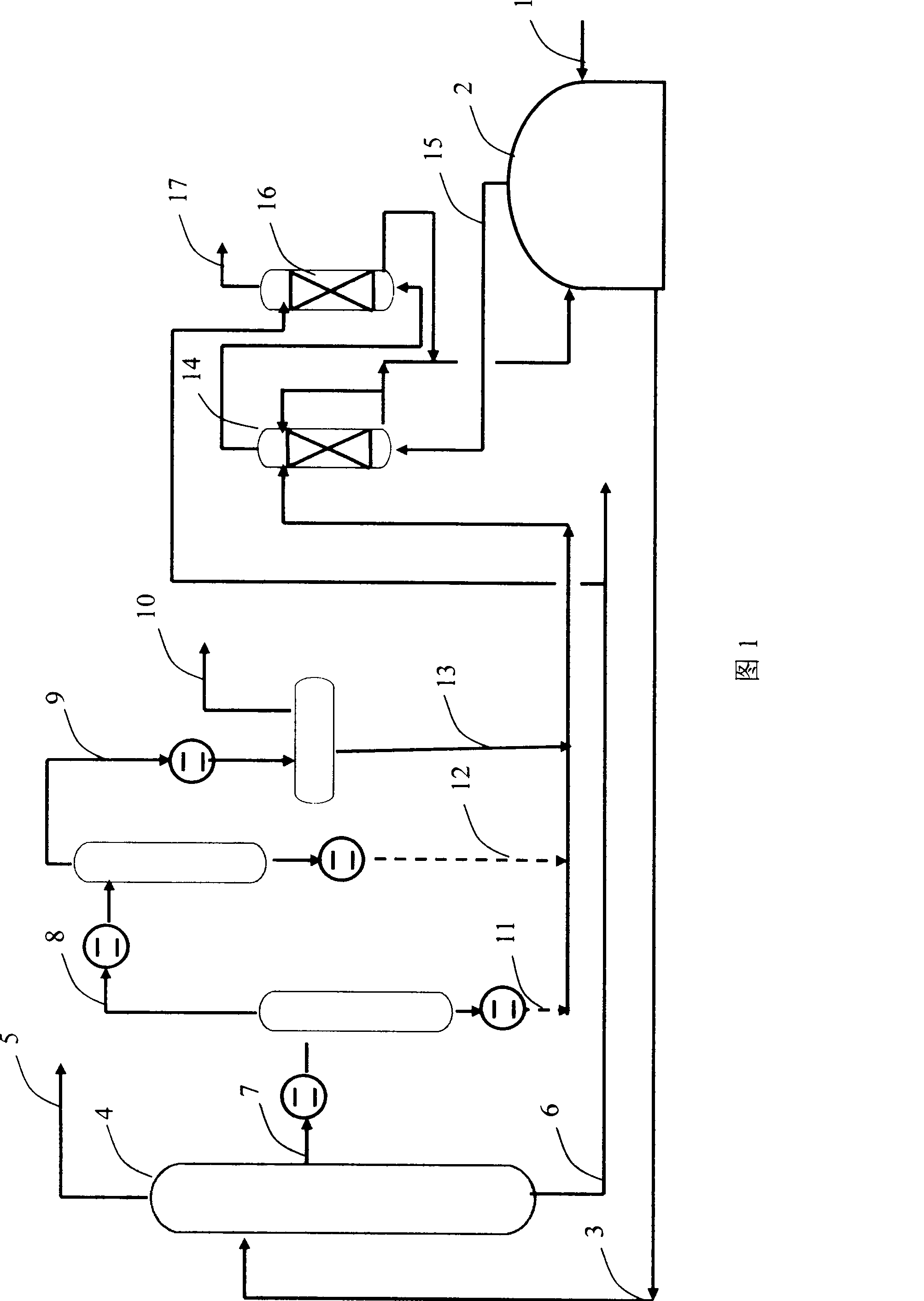

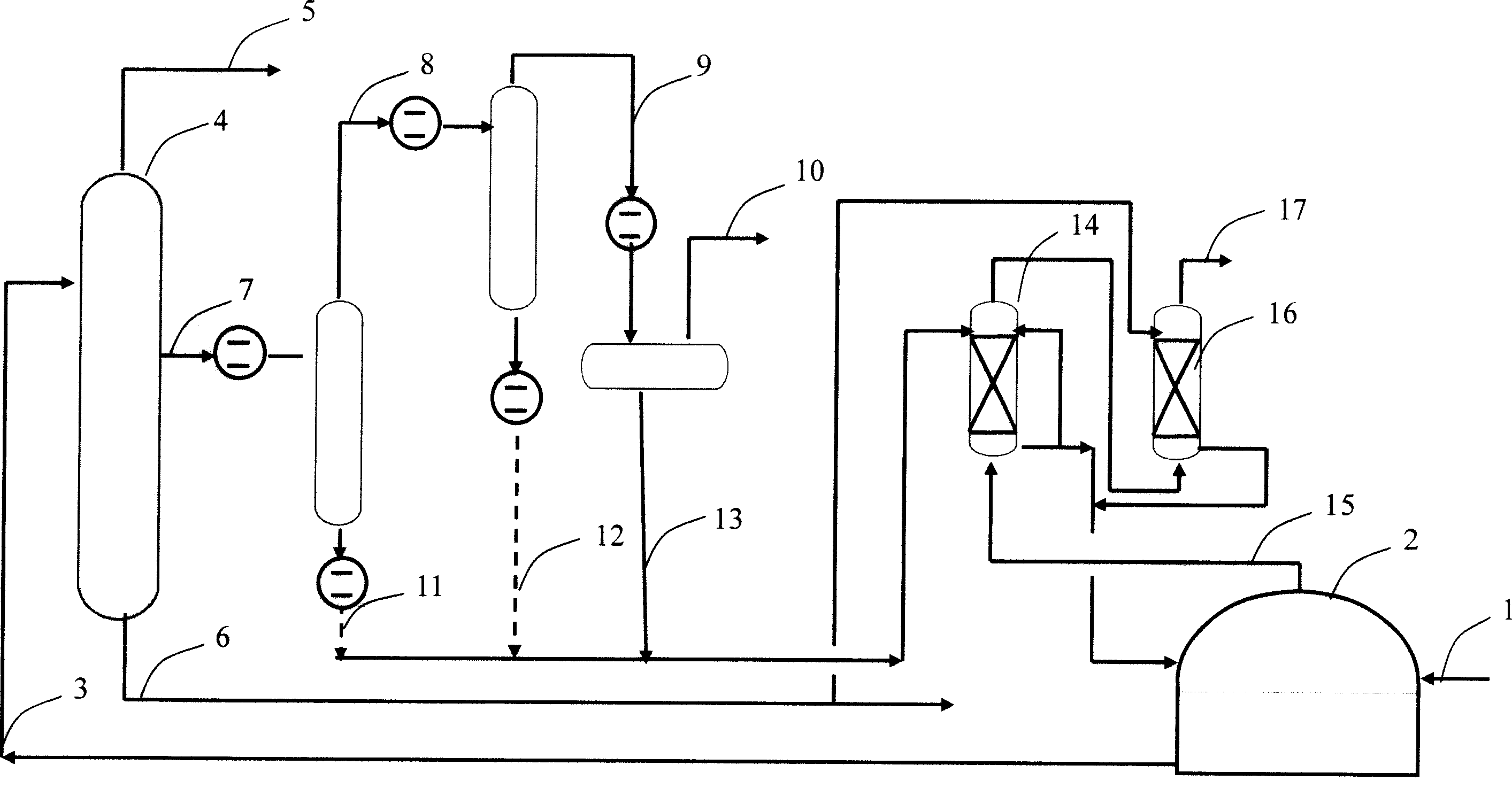

Method used

Image

Examples

Embodiment 1

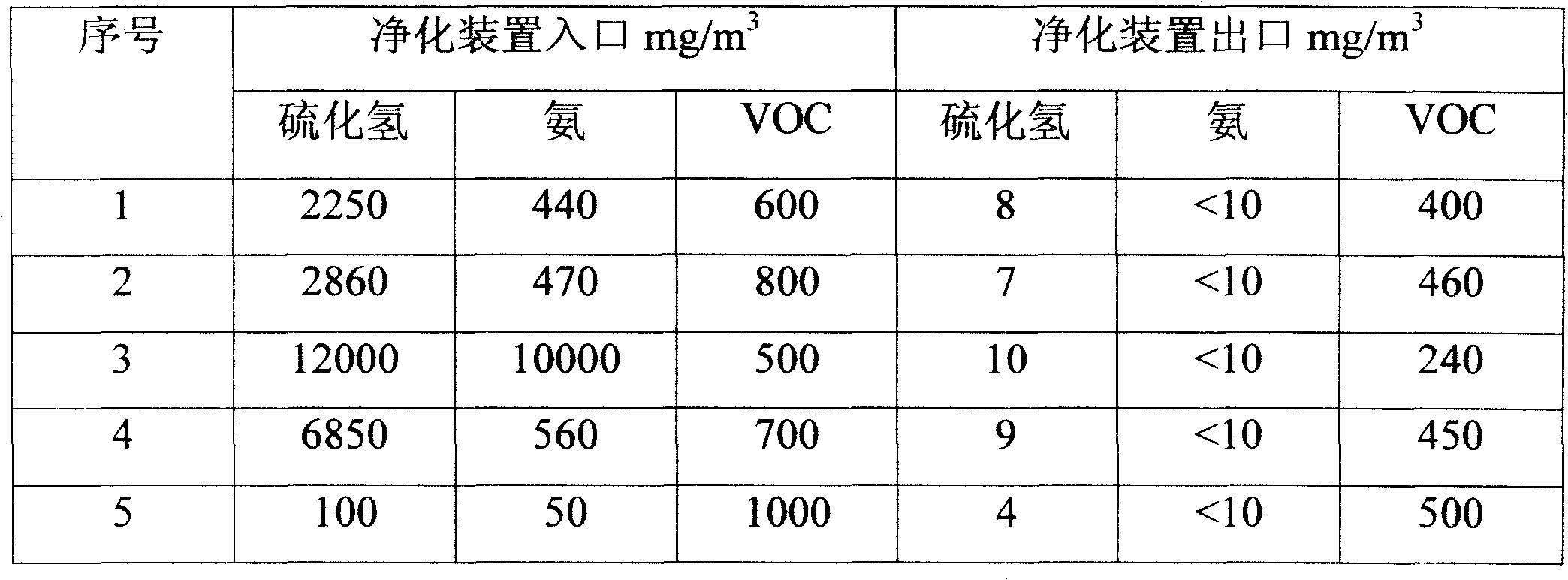

[0018] An enterprise's sour water storage tank emits about 1000m3 of gas 3 / h, the composition of main odor pollutants is shown in Table 1. The extraction and condensation of the side line of the stripper is 3-stage condensation, in which the weight concentration of the condensed liquid ammonia in the third stage of condensation is about 30%, the concentration of hydrogen sulfide in the purified water by stripping is 5-15 mg / L, and the concentration of ammonia is 20-50 mg / L. The above two liquids are used as the absorption liquid for the purification treatment of the exhaust gas of the acidic water storage tank.

[0019] Table 1 Concentration of main odor pollutants in the discharge gas of acidic water storage tanks

[0020] Main types of odor

Odor species concentration (mg / m 3 )

100~12000

[0021] Main types of odor

Odor species concentration (mg / m 3 )

organic sulfide

10~2000

ammonia

...

Embodiment 2

[0026] According to the method described in Example 1, wherein the filler adopts Dg38 stainless steel saddle ring. The diameter of the first-stage eluting tower is 600mm, and the height of the packing layer is 2600mm. The eluent comes from the acidic water stripping ammonia gas condensate system, which is a mixed solution of the second-stage condensate and the third-stage condensate. , liquid-gas ratio 6~8L / m 3 ; The diameter of the second-stage elutriation tower is 700mm, the height of the packing layer is 3500mm, the eluent is stripped purified water, and the liquid-gas ratio is 12-15L / m 3 . The operating temperature of the first-stage rinsing and the second-stage rinsing is controlled at 35°C to 45°C. The eluent of the first-stage packed tower is recycled in the tower, and when the pH value of the eluent drops to 9, a new fractionated condensate is added. The eluent of the second-stage packed tower is not circulated. The effluent from both the first stage rinse and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com