Method for cleaning machine-made component

A technology of components and cleaning media, applied in the direction of cleaning methods and appliances, chemical instruments and methods, etc., can solve problems such as limited effects, achieve the effects of reduced cleaning costs, improved cleaning efficiency, and good market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

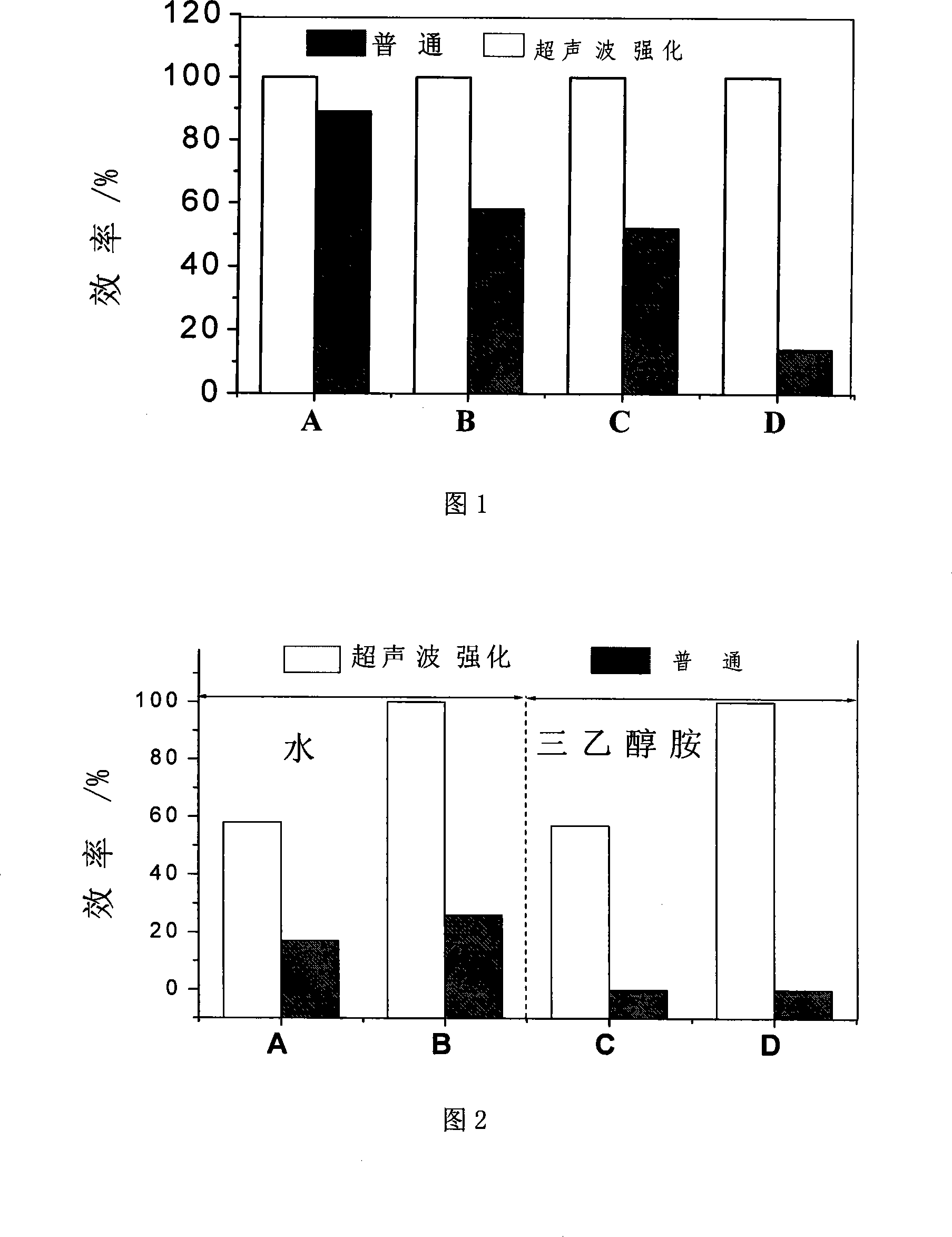

[0014] Fig. 1 is a schematic diagram showing the effect comparison between the cleaning method of the present invention and the conventional cleaning method for machined parts polluted by engine oil. The cleaning reaction conditions in the figure are: A 100°C, 10MPa; B 60°C, 10MPa; C 25°C, 10MPa; D 25°C, 7MPa.

[0015] It can be seen from the figure that under the four cleaning conditions of A, B, C and D, after the introduction of ultrasonic agitation, the cleaning ability of the supercritical carbon dioxide fluid to the residual oil on the surface of the parts has been significantly improved. The weight change of the sample before and after cleaning The data show that supercritical carbon dioxide under the action of ultrasonic waves cleans the engine oil on the surface of the sample very thoroughly, and the efficiency converted from the weighing data is about 100%. Oil in blind holes with internal threads in complex components is also efficiently removed during cleaning. Es...

Embodiment 2

[0017] Fig. 2 is a schematic diagram showing the effect comparison of drying and dehydration of wet filter paper and cleaning of residual coolant additive triethanolamine on the surface of machined parts by using the present invention and conventional methods. The cleaning reaction conditions in the figure are: A 10MPa, 60°C; C 10MPa, 60°C; B 15MPa, 60°C; D 10MPa, 100°C. It can be seen from the figure that the supercritical carbon dioxide can significantly improve the desiccation and drying ability of supercritical carbon dioxide on the moisture absorbed by the wet filter paper by ultrasonic stirring. . Static supercritical carbon dioxide at 60°C and 10MPa basically has no cleaning effect on triethanolamine, a common machining coolant additive. When ultrasonic waves are introduced to stir the cleaning, 57% of triethanolamine is removed from the surface of the cleaning sample by carbon dioxide. Increase the cleaning temperature to 100°C, and ultrasonic agitation makes the clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com