Heat-resisting oxidation-resistance nitrogen-containing anisotropic rare earth permanent magnet alloy powder and preparation thereof

An anisotropic, rare-earth permanent magnet technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problem of decreased magnetic performance, small amplitude reduction of anisotropy field, reduction of saturation magnetization and anisotropy field and other problems, to achieve the effect of good anti-oxidation performance, low oxygen content and high service temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

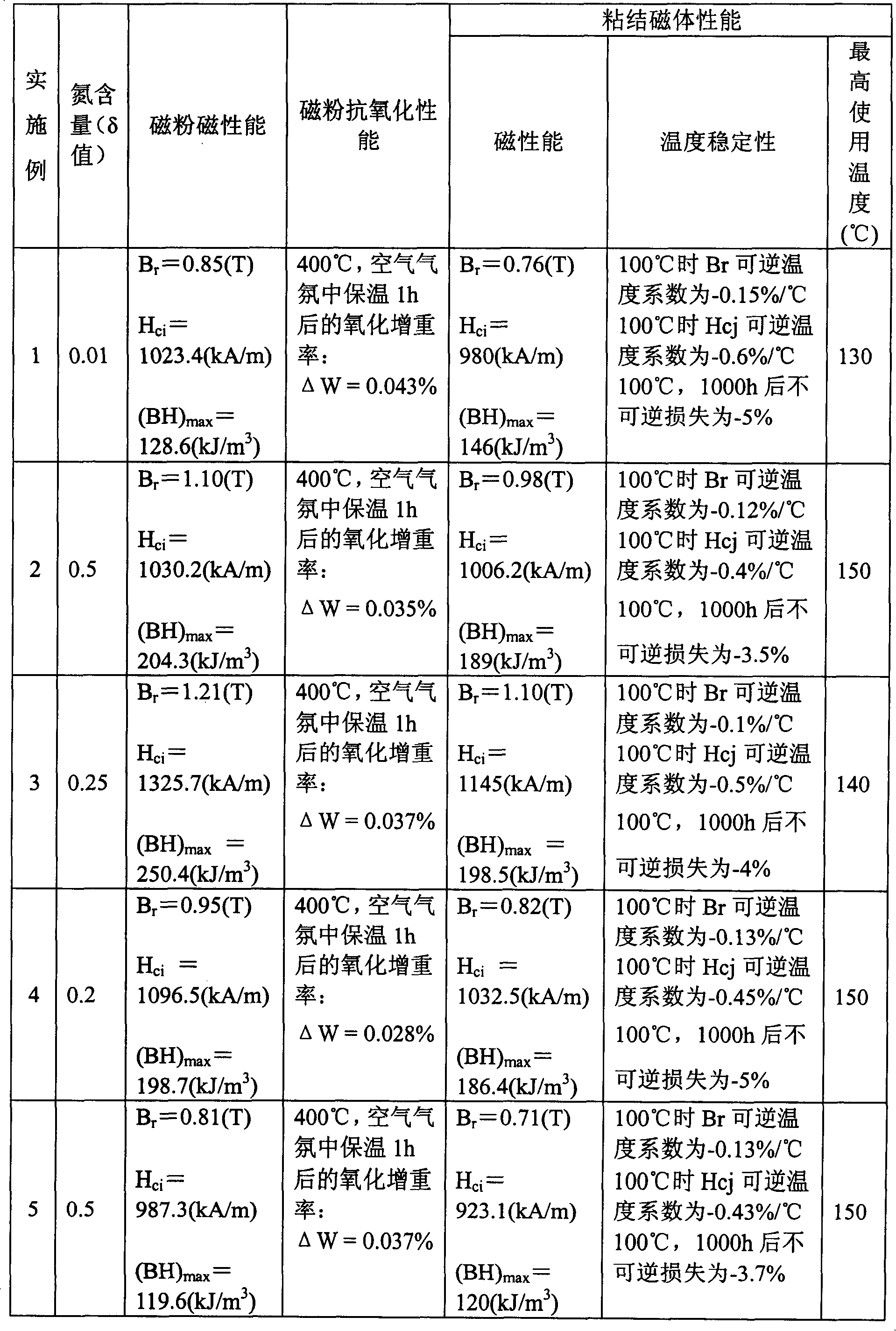

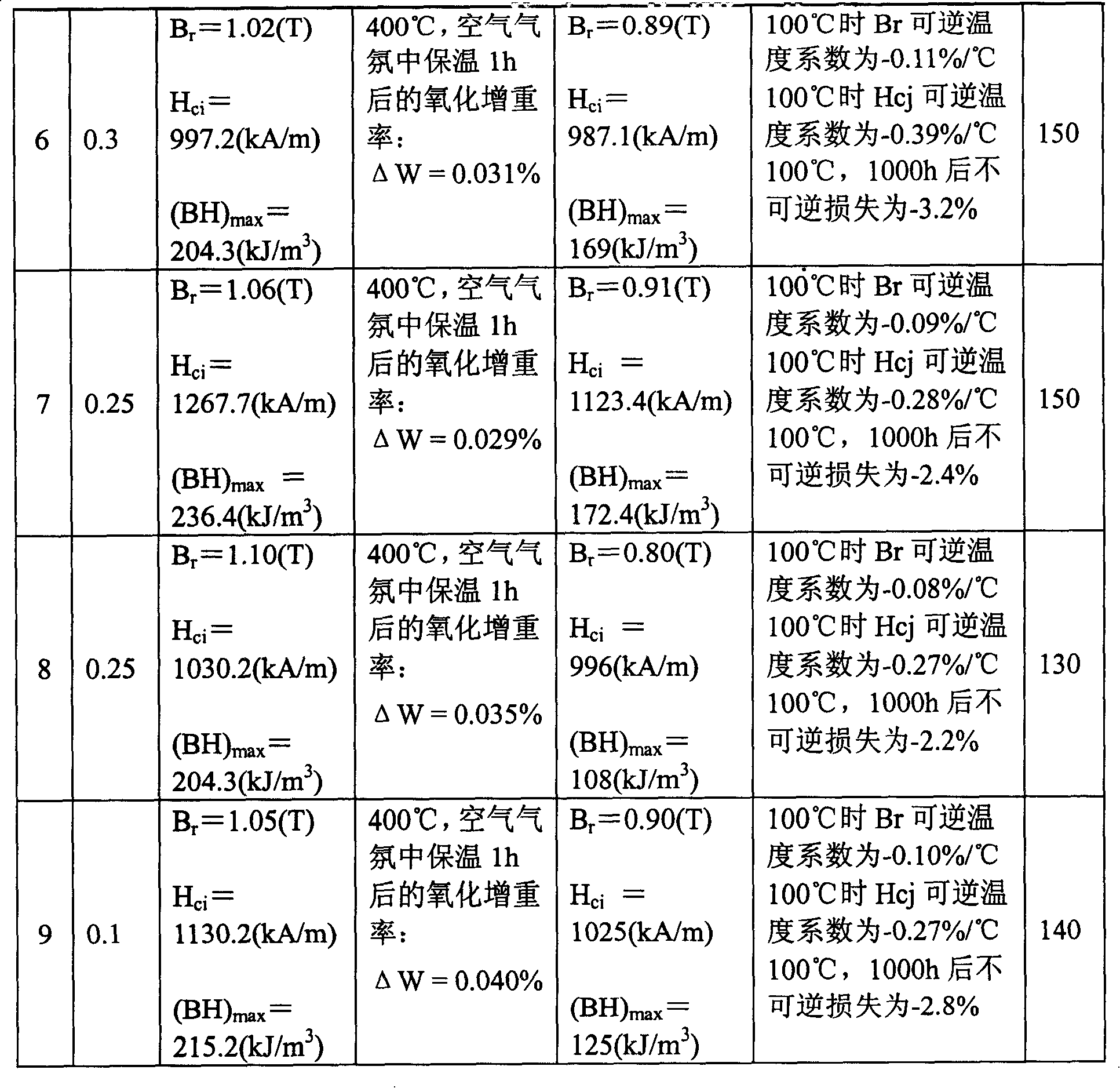

Examples

Embodiment 1

[0028] A thin plate-shaped alloy ingot with a composition of 20Nd7.8Pr1.2Dy66.7Fe1.5Co1.5Ga0.25Nb1.05B is broken into small pieces of alloy in a jaw crusher under the protection of an inert gas, and then placed in a hydrogenation furnace. Vacuum down to 1×10 -3 Pa, and then feed 0.2MPa high-purity hydrogen gas to make the raw material absorb hydrogen to saturation at room temperature. When the hydrogen pressure does not change significantly, the alloy material is slowly heated to 720°C and kept for 5 hours. During the whole heating process, the hydrogen pressure is continuously replenished, and the hydrogen pressure is always kept at 50KPa. Then rapidly raise the temperature to 750°C and keep it warm for 30 minutes, the hydrogen pressure is 5KPa. Then evacuate to 1×10 -3 Pa, rapidly cooled to room temperature.

[0029] Put the above-mentioned treated powder in the nitriding reaction furnace and vacuumize to 1×10 -3 After Pa, feed high-purity nitrogen with a nitrogen pressu...

Embodiment 2

[0034] The alloy rapid cooling thick strip with the composition of 20Nd7.8Pr1.2Dy66.7Fe1.5Co1.5Ga0.25Nb1.05B is broken into small pieces of alloy in a jaw crusher under the protection of inert gas, and then placed in a hydrogenation furnace. Vacuum down to 1×10 -3 Pa, and then 0.1MPa of high-purity hydrogen is introduced to make the raw material absorb hydrogen to saturation at room temperature. When the hydrogen pressure does not change significantly, the alloy material is slowly heated to 820°C and kept for 1 hour. During the whole heating process, the pressure is adjusted at any time and kept at 30KPa. Then rapidly raise the temperature to 850°C and keep it warm for 60 minutes, the hydrogen pressure is 3KPa. Then evacuate to 1×10 -3 Pa, rapidly cooled to room temperature.

[0035] Put the above-mentioned treated powder in the nitriding reaction furnace and vacuumize to 1×10 -3 After Pa, feed high-purity nitrogen with a nitrogen pressure of 1.5MPa; then heat up to 600°C ...

Embodiment 3

[0040] Under the protection of inert gas, the alloy rapid cooling thick strip with the composition of 20Nd7.8Pr1.2Dy69.26Fe0.5Al0.14Cu1.1B is broken into small pieces of alloy in a jaw crusher, and then placed in a hydrogenation furnace and vacuumized to 1×10 -3 Pa, and then 0.15MPa high-purity hydrogen gas is introduced, and heated to 400°C, so that the raw material absorbs hydrogen to saturation. When the hydrogen pressure does not change significantly, the alloy material is slowly heated up to 770°C and kept for 3 hours. During the whole heating process, the pressure is adjusted at any time and kept at 40KPa. Then rapidly raise the temperature to 800°C and keep it warm for 45 minutes, with the hydrogen pressure at 1KPa. Then evacuate to 1×10 -3 Pa, rapidly cooled to room temperature.

[0041] Put the above-mentioned treated powder in the nitriding reaction furnace and vacuumize to 1×10 -3 After Pa, feed high-purity nitrogen gas with a nitrogen pressure of 1 MPa; then he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com