Forcible air cooling internal combustion engine

An air cooling, internal combustion engine technology, applied in the direction of engine cooling, mechanical equipment, engine components, etc., can solve the problem of difficult to use cooling internal combustion engine and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Hereinafter, referring to the drawings, a mode of the present invention will be described according to one embodiment of the present invention.

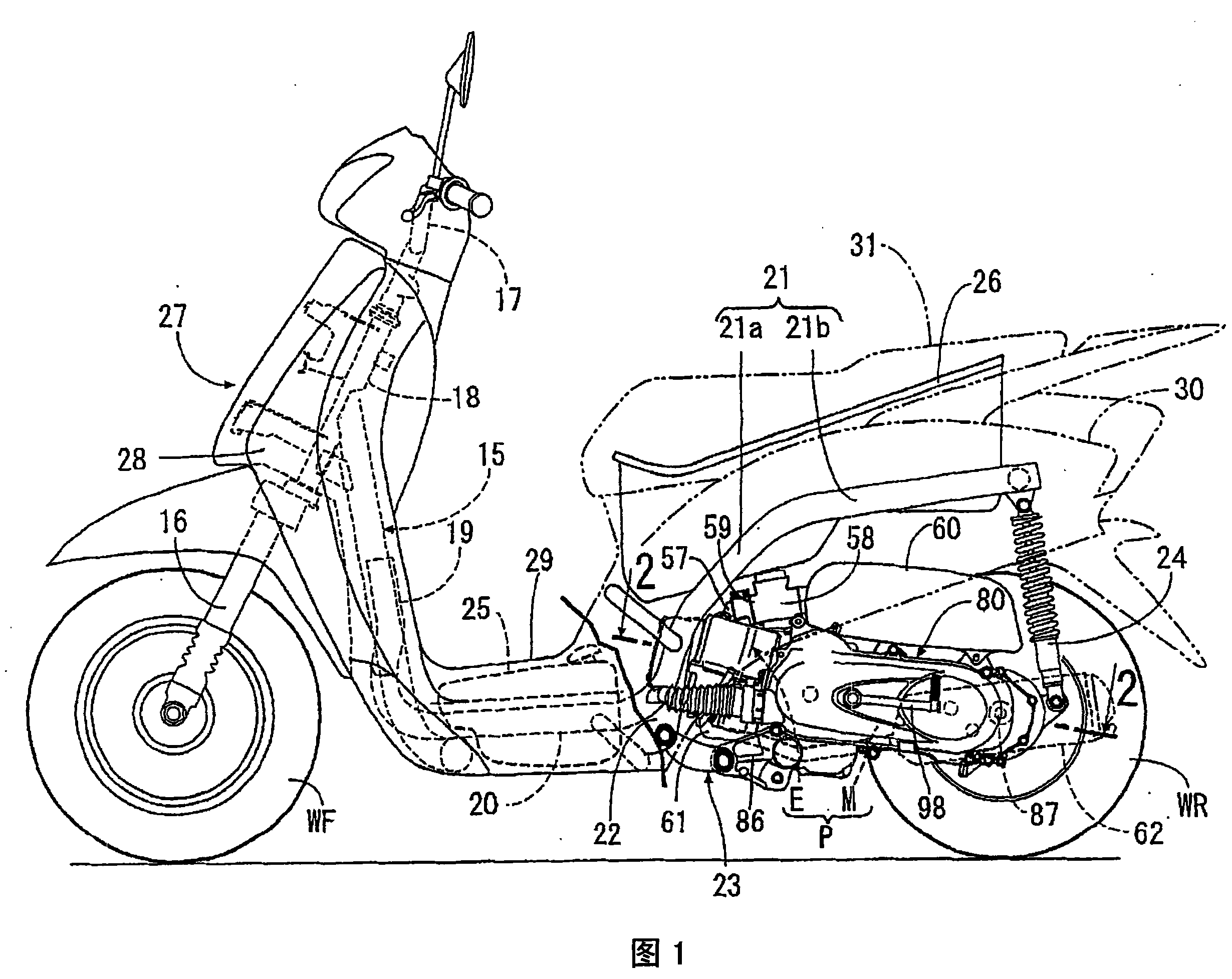

[0065] As shown in FIG. 1 , the body frame 15 of the scooter includes a head pipe 18 that steerably receives a front fork 16 to which a front wheel WF is journalled with a steering handle 17 . A down tube 19 extends rearward and downward from the head pipe 18 . A pair of left and right lower frame tubes 20 extend rearward, and the pair of left and right lower frame tubes 20 have front ends respectively fixed to lower sides of the down tube 19 . A pair of left and right rear frame tubes 21 is integrally connected to the rear end of the lower frame tube 20 . Each rear frame tube 21 includes a rising frame portion 21a and an upper frame portion 21b, the rising frame portion 21a extends backward and upward from the rear end of each lower frame tube 20, and the upper frame portion 21b extends from the rear end of the rising frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com