Horizontal type agitated bed reactor inner caking detection method and apparatus

A technology of a horizontal stirred bed and a detection method, which is applied to measuring devices, chemical/physical/physicochemical stationary reactors, vibration measurement in fluids, etc., can solve the problems of unsatisfactory detection sensitivity and complexity, and meet the measurement conditions The effect of low requirements, small measurement error and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

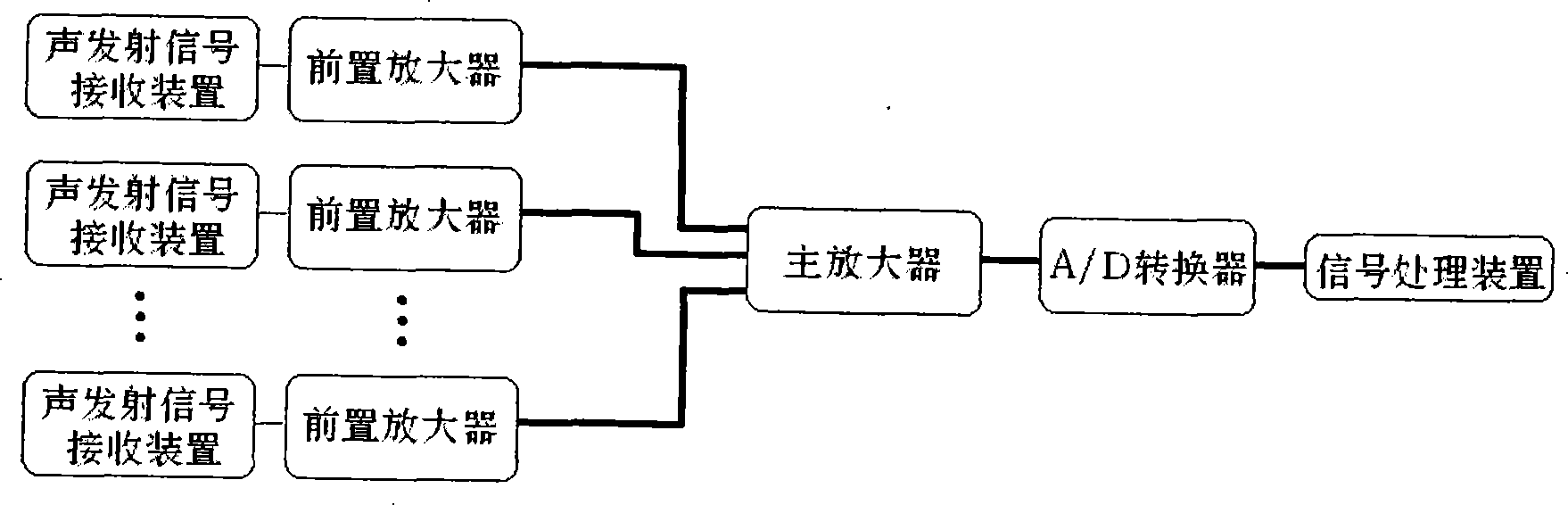

Method used

Image

Examples

Embodiment 1

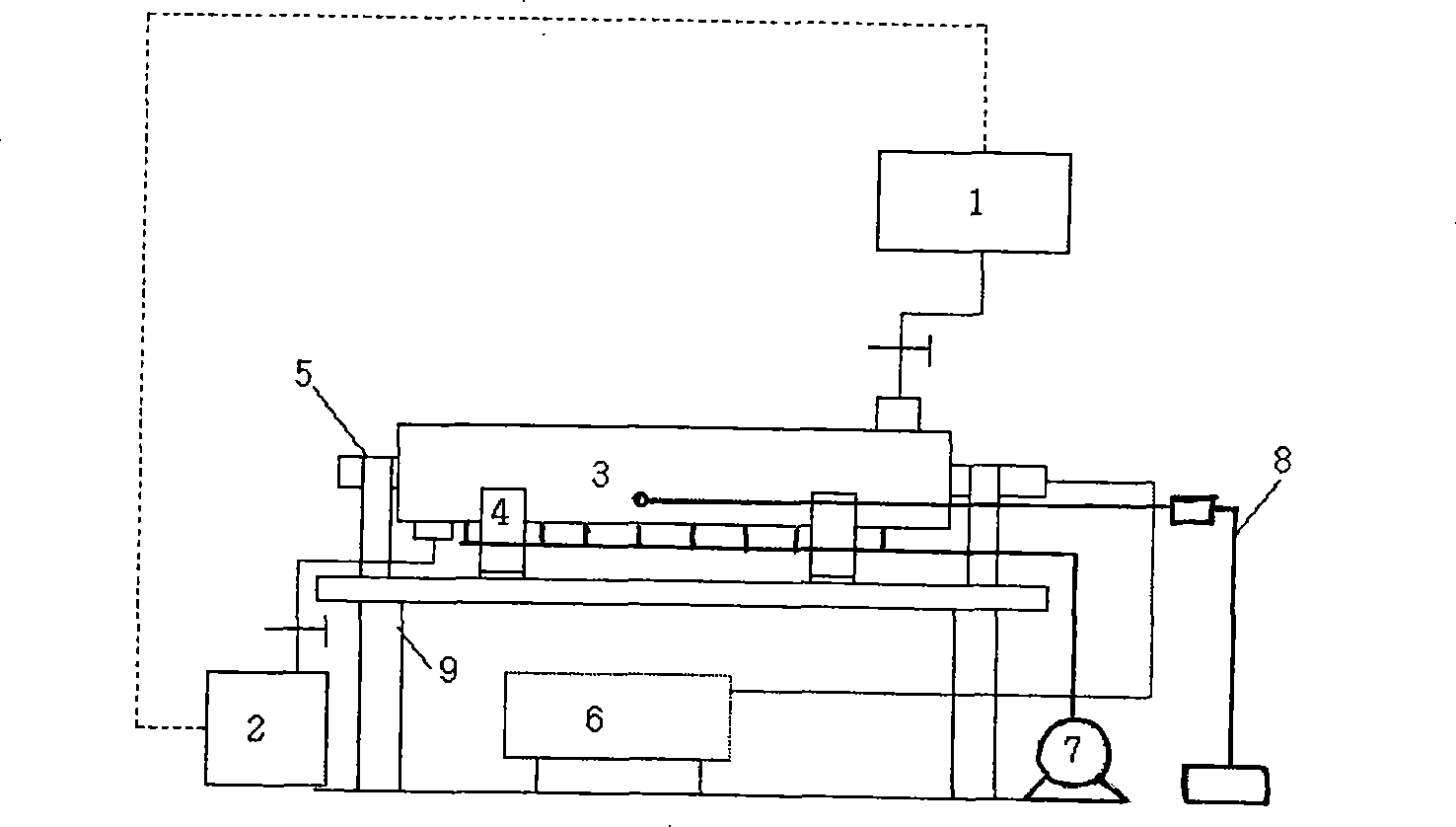

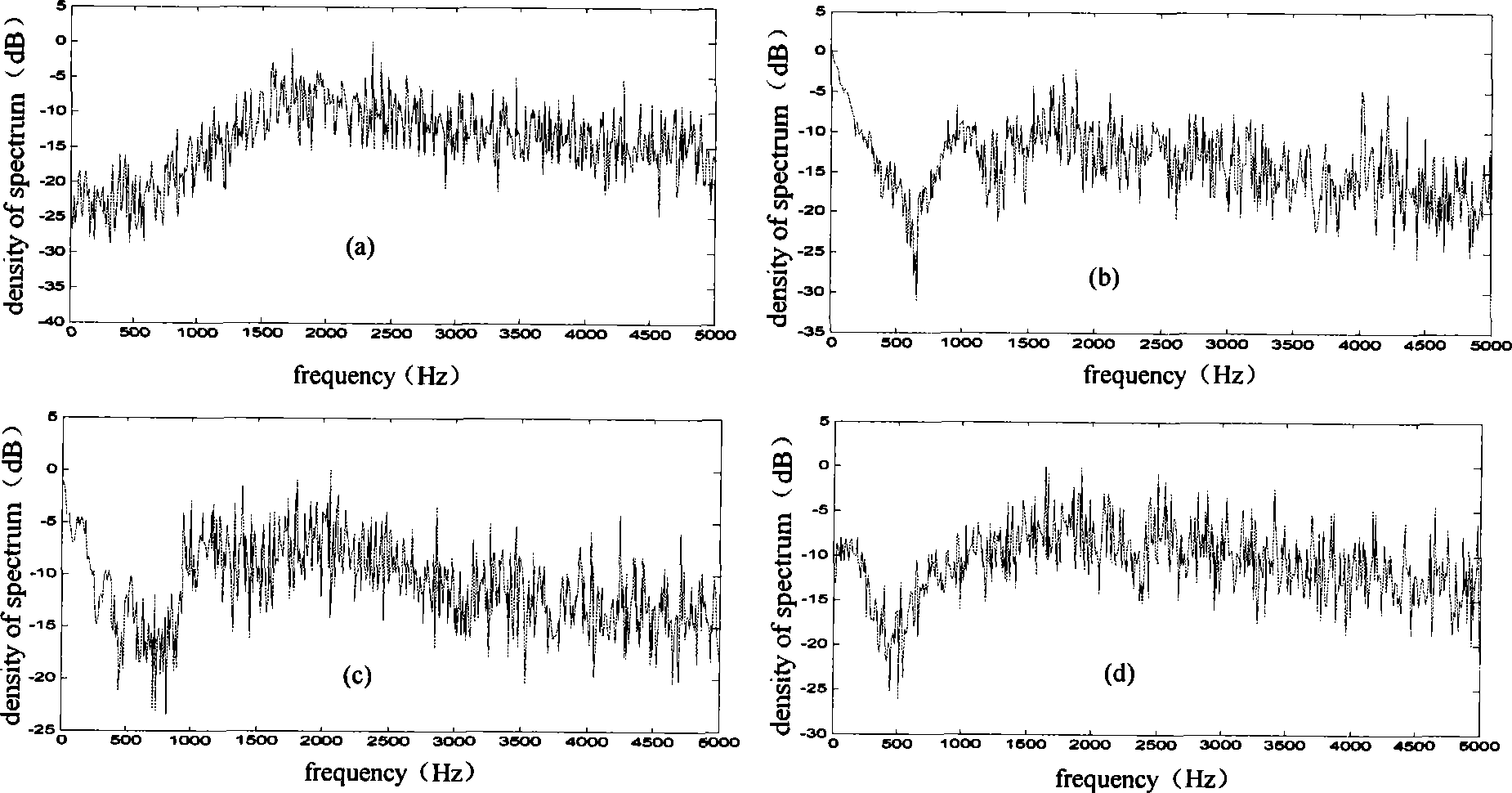

[0045] The cold mold device of the horizontal stirred bed reactor is built in the laboratory, such as figure 2 shown. The reactor is made of transparent plexiglass, with a length of 1530mm and an inner diameter of 475mm. The stirring paddle is blade-type, made of stainless steel, and the rotation speed is 30rpm. The acoustic emission signal is measured with an acoustic wave measuring instrument. The acoustic wave measuring instrument includes an acoustic wave receiving device, an amplifying device, a signal collecting device and a signal processing device. The acoustic sensor is placed at the bottom of the tank, the sampling frequency is 10000 Hz, the sampling time is 10 s, and the sampling interval is 1 min. The powder used in the experiment is linear low-density polyethylene particles (LLDPE, produced by Sinopec Tianjin Branch), and its melt index and density are 2.0g / 10min and 920kg / m3 respectively. 3 , the average particle size is 833 μm, and the particle size distribut...

Embodiment 2

[0053] The agglomeration detection in a horizontal reactor was carried out on an industrial grade polypropylene device in a factory by using acoustic emission technology. The length of the reactor is 13700mm, the inner diameter is 2743mm, the material is stainless steel, and the rotation speed of the stirring blade is 15r / min. Acoustic emission signals are measured by acoustic wave measuring instruments, which include acoustic wave receiving devices, amplifiers, signal acquisition devices and signal processing devices, with a sampling frequency of 1MHz, a sampling time of 10s, and a monitoring interval of 12 minutes.

[0054] According to the quality of the powder at the discharge port and the corresponding parameters (T, P) of the reactor, it is judged whether the reactor is in a normal production state, and the acoustic emission signal is collected at the same time to obtain the ARMA power spectrum model of the acoustic emission signal of the reactor in the normal state.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com