Fish meat petroleum hydrocarbon content determination method

A technology of petroleum hydrocarbon content and determination method, which is applied in the field of food

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

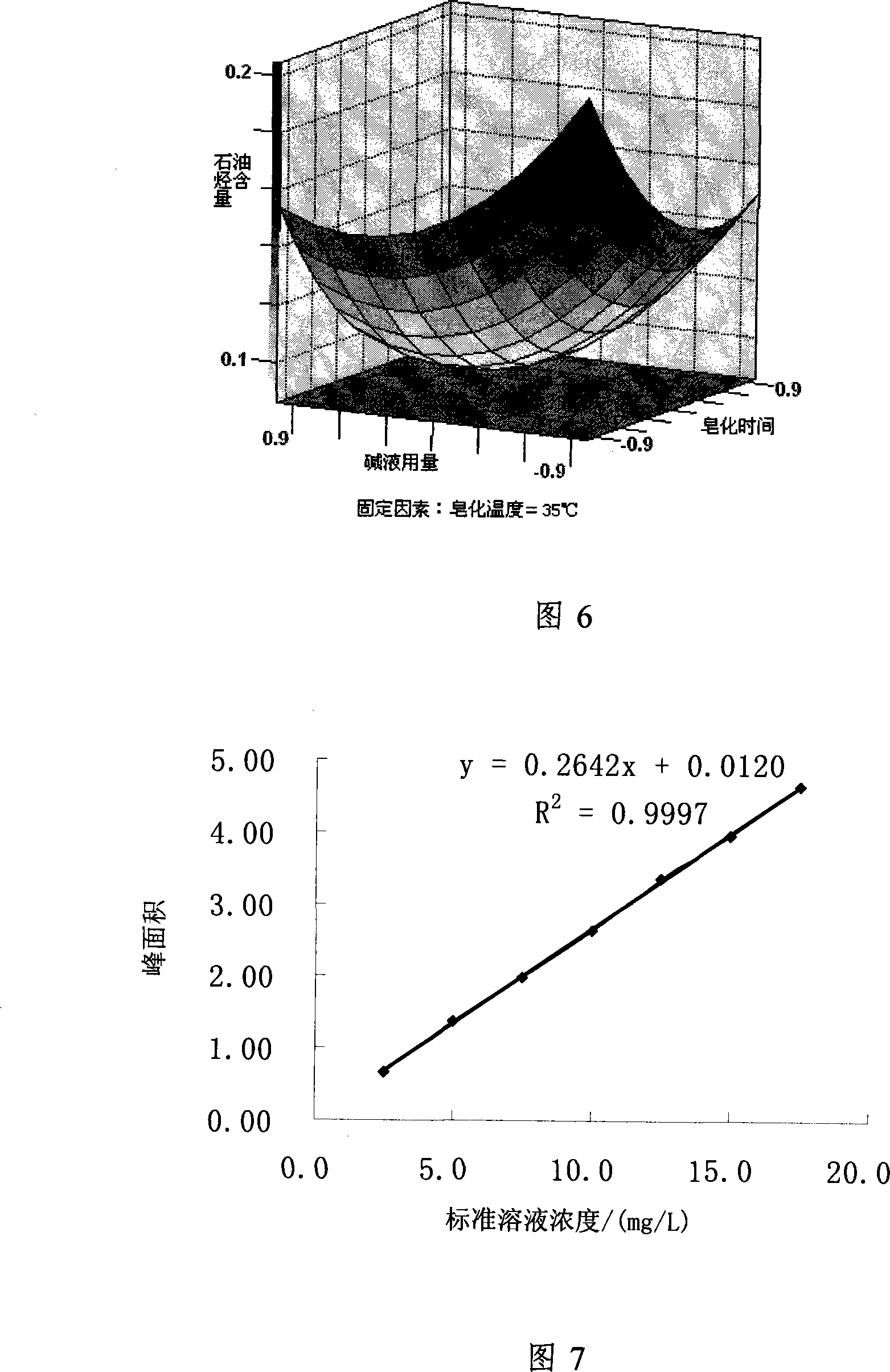

[0129] Determination of petroleum hydrocarbon content in silver carp of embodiment 1

[0130] Follow the steps below to measure:

[0131] 1. Fish processing steps

[0132] The silver carp purchased from Qingshan Market is descaled and peeled, and its meat is taken, and then the JJ-2 tissue mashing and homogenizing machine produced by Jiangsu Changzhou Guohua Instrument Factory is used to mash and mix, and the obtained fish paste is placed in a sealed container. Store in a glass bottle at -20°C for later use.

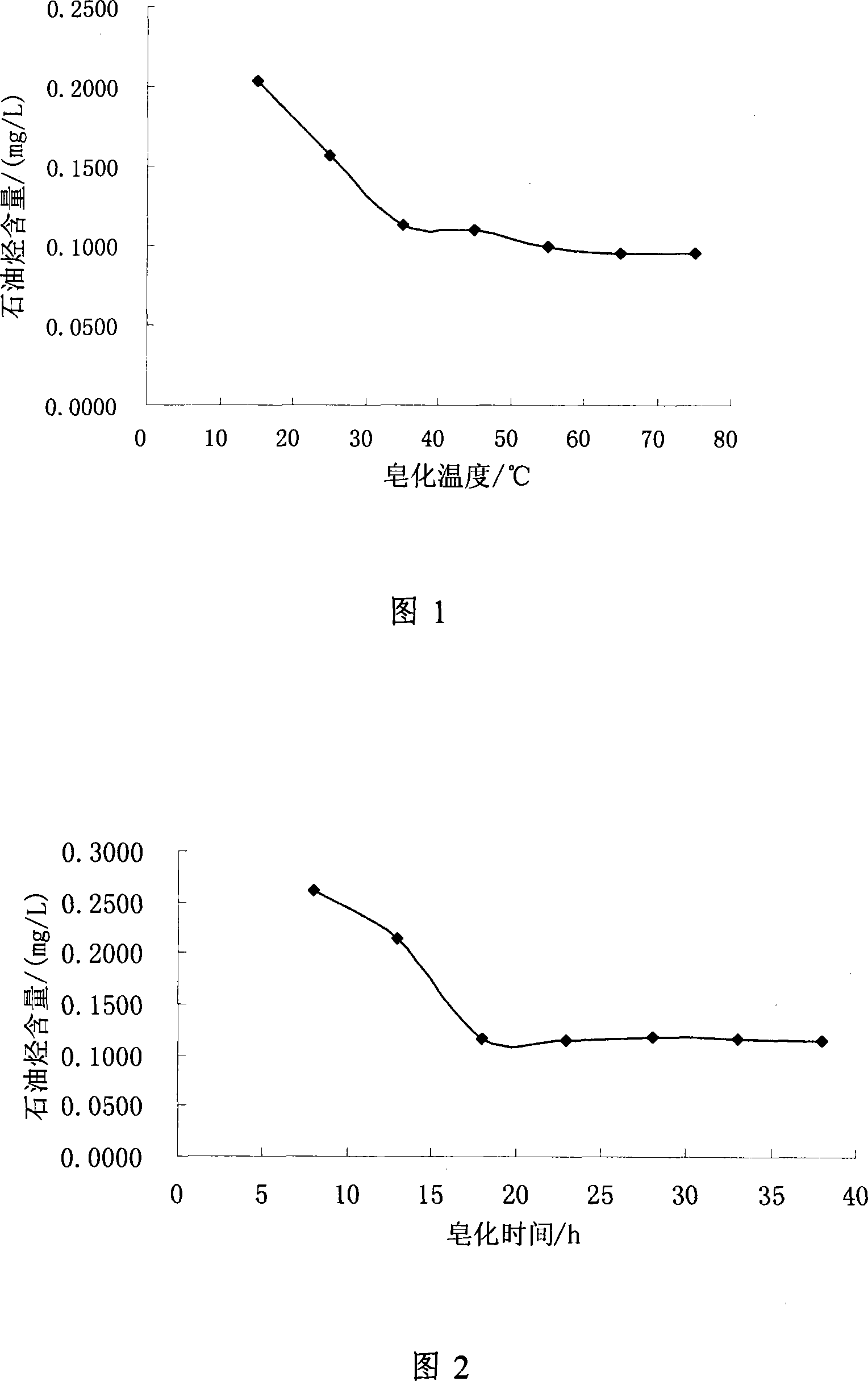

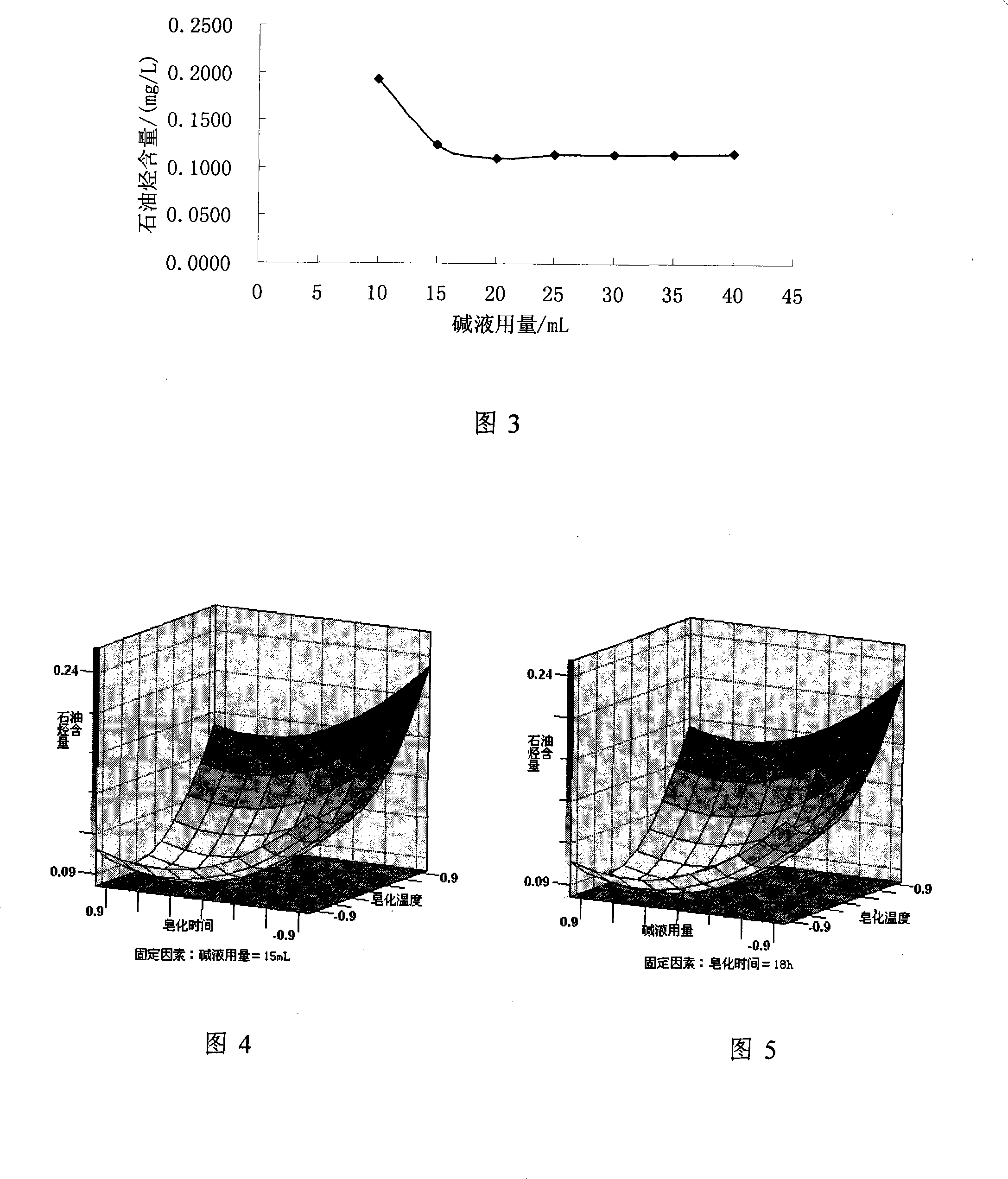

[0133] 2. Saponification of fish meat

[0134] Thaw the fish meat paste obtained in step (1), weigh 2.5 grams of fish meat paste and place it in an iodine measuring bottle, add 15 ml of 5mol / L analytically pure sodium hydroxide solution (deionized water, meeting the first-grade water standard in GB / T 6682 , Sinopharm Group Chemical Preparations Co., Ltd.), adding 20 mL of absolute ethanol, shaking and saponifying at 30 ° C for 20 h, to obtain fish digestion solution. ...

Embodiment 2

[0156] Determination of Petroleum Hydrocarbon Content in Grass Carp in Embodiment 2

[0157] Follow the steps below to measure:

[0158] 1. Fish processing steps

[0159] Grass carp purchased from the Qingshan market is descaled and skinned, and the meat is taken, and then mashed and mixed with the JJ-2 tissue smashing and homogenizing machine produced by Jiangsu Changzhou Guohua Instrument Factory. The obtained fish paste is placed in a sealed glass bottle Stored at -20°C for later use.

[0160] 2. Saponification of fish meat

[0161] Thaw the fish paste obtained in step (1), weigh 2.8g of fish paste and place it in an iodine bottle, add 15mL of 6mol / L analytically pure sodium hydroxide solution (deionized water, in line with the first-grade water standard in GB / T 6682 , Sinopharm Group Chemical Preparations Co., Ltd.), adding 15 mL of absolute ethanol, shaking and saponifying at 30 ° C for 20 h, to obtain fish digestion solution.

[0162] 3. Extraction and adsorption

...

Embodiment 3

[0176] Petroleum hydrocarbon content determination in the squid of embodiment 3

[0177] Follow the steps below to measure:

[0178] 1. Fish processing steps

[0179] Get its meat from the squid purchased in Qingshan Market, then use the JJ-2 tissue smashing and homogenizing machine produced by Jiangsu Changzhou Guohua Instrument Factory to mash and mix, and the obtained fish paste is placed in a sealed glass bottle and heated at a temperature of -20 Store at ℃ for later use.

[0180] 2. Saponification of fish meat

[0181] Thaw the fish meat paste obtained in step (1), weigh 2.3 grams of fish meat paste and place it in an iodine measuring bottle, add 20 mL of 6mol / L analytically pure sodium hydroxide solution (deionized water, in line with the first-grade water standard in GB / T 6682 , Sinopharm Group Chemical Preparations Co., Ltd.), adding 15 mL of absolute ethanol, shaking and saponifying at 35° C. for 18 h, to obtain the fish digestion solution.

[0182] 3. Extraction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com