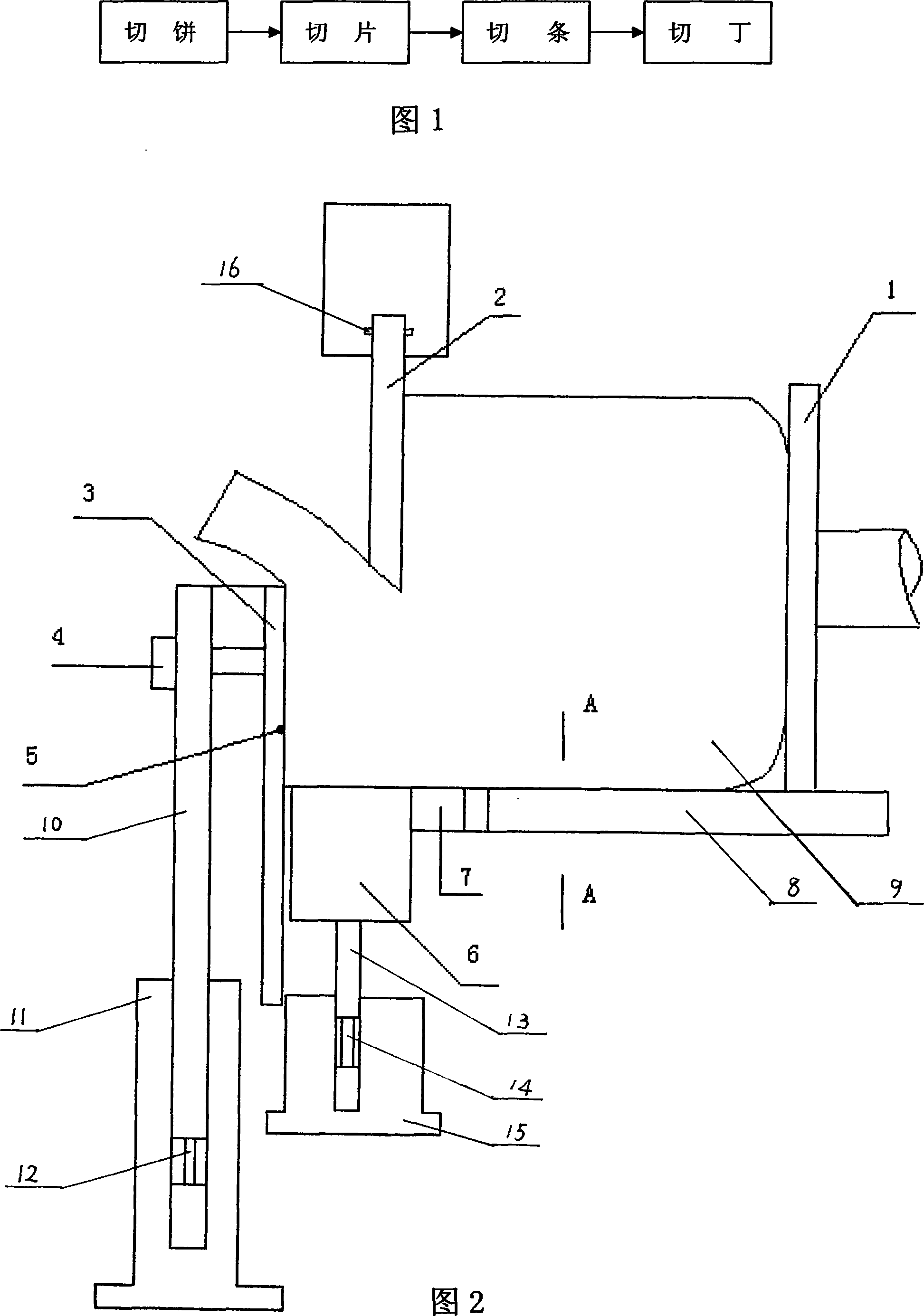

Titanium sponge pulverizing method and apparatus

A technology of a crushing device and a crushing method, which is applied to shearing devices, accessories of shearing machines, and equipment of shearing machines, etc., can solve the problems of low processing efficiency, long process flow and poor performance, and achieve high processing efficiency, Short process flow and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

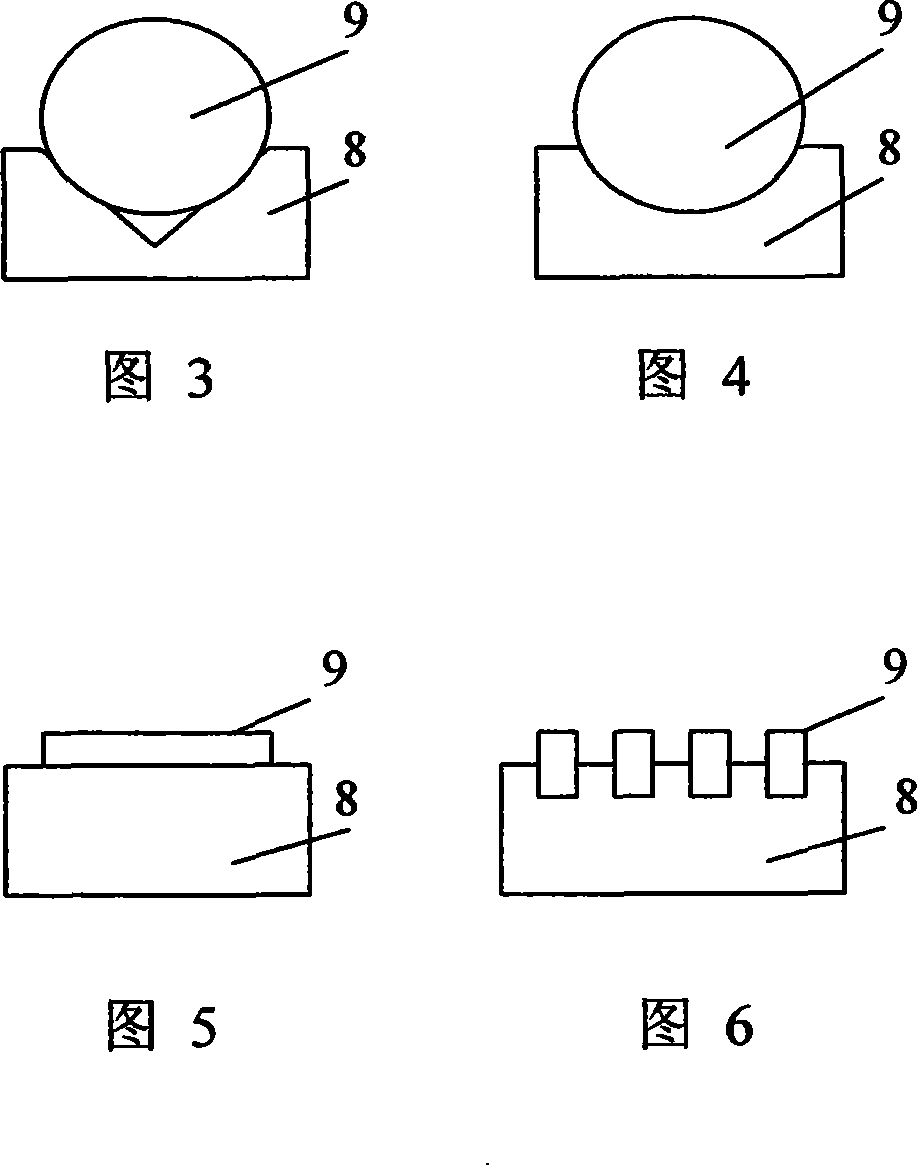

[0029] First introduce the shearing device of the present invention, see Fig. 2 to Fig. 6: this device comprises sponge titanium material supporting slideway 8, is arranged in the sponge titanium material propelling device 1 of this supporting slideway 8 afterbody, is fixed on supporting slideway head The lower shear 7 on the end face is arranged on the upper shear device 2 above the support slideway 8. The upper shear device has a driving and transmission device that makes it reciprocate up and down. The shears of the upper shear device 2 and the lower shear 7 The blades face each other and correspond. Above is the basic structure of known existing sponge titanium shearing device. The present invention has done following improvement on this basis:

[0030] 1. In front of the head of the supporting slideway, a titanium sponge limiting device is added.

[0031] The titanium material limiting device includes a vertically arranged sliding seat / slideway pair, the sliding seat 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com