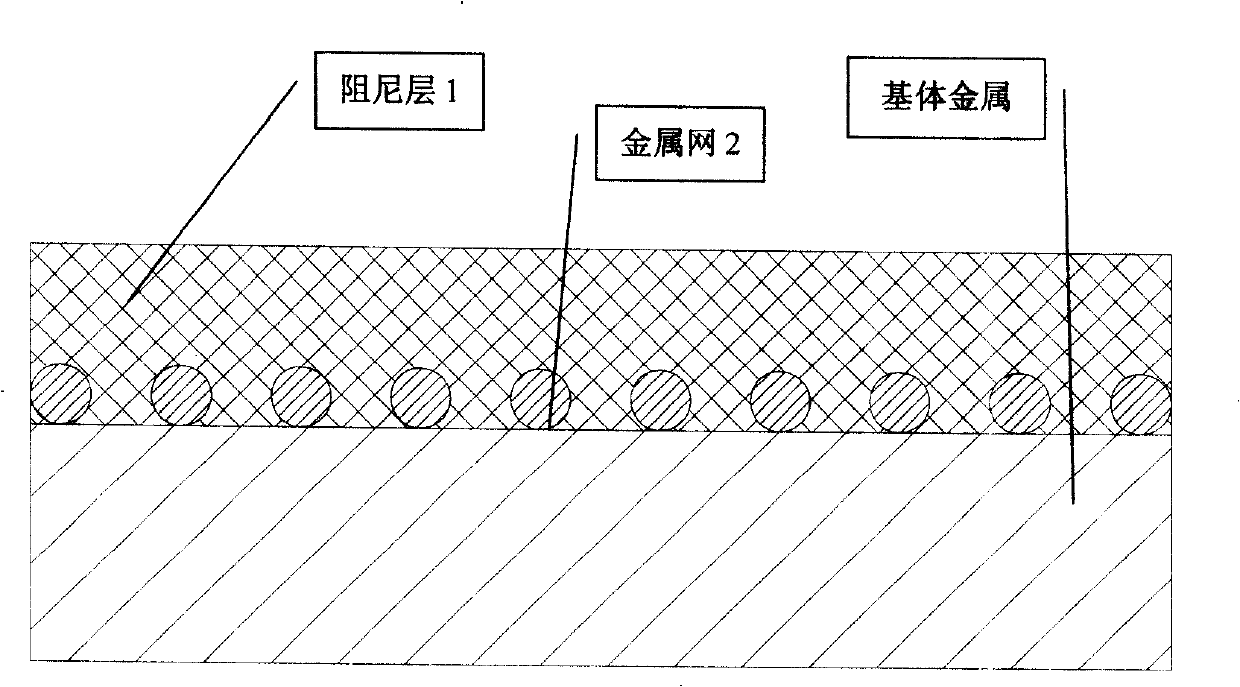

Metal net plate damping composite material and method for manufacturing same

A damping composite material, metal mesh plate technology, applied in metal layered products, chemical instruments and methods, lamination devices, etc., can solve the problems such as the inability to increase the bonding strength with the metal matrix, short service life, etc., and achieve low manufacturing costs. , the effect of prolonging the service life and increasing the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

[0019] A simple mold is used to directly cast manganese brass, a metal damping material, in the mesh holes and on the surface of the metal mesh composite plate to form a metal mesh plate manganese brass damping composite material. It increases the strength of manganese brass, and also prevents hot-rolled cladding, and the stress cracking problem of thick manganese brass in explosive welding cladding.

specific Embodiment approach 3

[0020] Lay a layer of barbed wire with a diameter of 1mm and a spacing of 2mm on the steel plate, and then lay a layer of glass cloth. After stacking three to six layers in total, put a layer of steel plate on it, and perform explosive compounding after compression. Carry out sealing welding. Due to the formation of many holes and fibers of different lengths between layers of glass cloth, the vibration and noise reduction effect is very good. The material is high temperature resistant, non-flammable, non-toxic and tasteless. It has high strength and is easy to connect with other structures. It is a promising vibration and noise reduction composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com