Method for manufacturing metallic absorbent charcoal

A technology of activated carbon and metal, which is applied to parts of fixed capacitors, electrical components, electrolytic capacitors, etc., can solve the problems of high raw material prices, complicated and harsh preparation processes, and source constraints, and achieve abundant sources, simple preparation processes, and well-developed pores Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

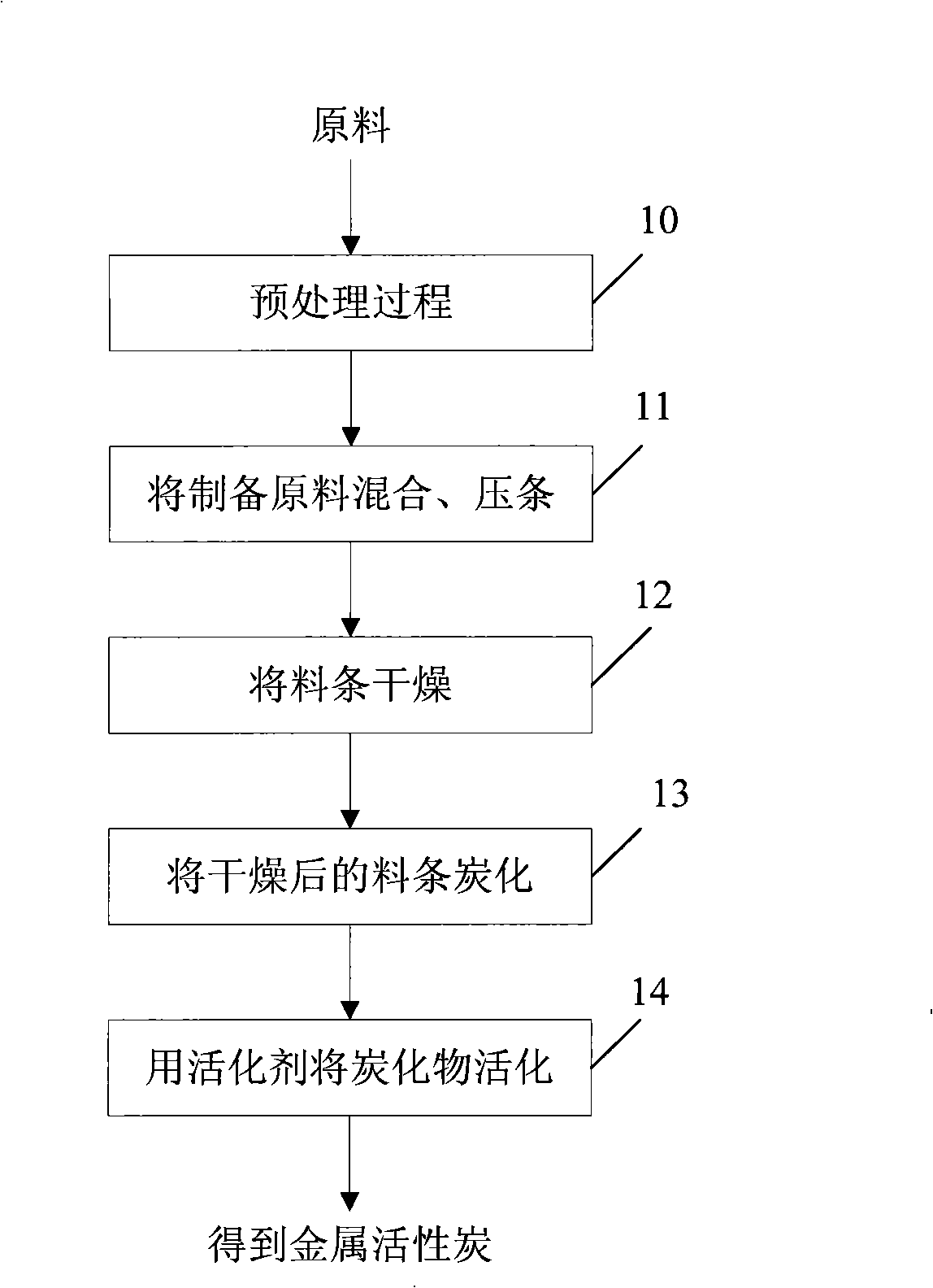

Method used

Image

Examples

Embodiment 1

[0033] Take 100g bituminous coal, 70gMn(NO 3 ) 2 Solution (50w%), 45g of coal tar, 0.5g of additives and an appropriate amount of water are mixed, kneaded and stirred, layered (φ2mm), and then dried at 80°C for 12h. Cut the dry strip into about 20mm long, carbonize at 600°C for 45 minutes, and then activate with water vapor at 850°C for 120 minutes, the BET specific surface area of the obtained metal activated carbon is 890m 2 / g, the total pore volume is 1.28cm 3 / g, when the metal activated carbon is used as capacitor electrode material, its specific capacitance is 328F / g.

Embodiment 2

[0035] Take 100g bituminous coal, 140gMn(NO 3 ) 2 Solution (50%w), 45g of coal tar, 0.5g of additives and appropriate amount of water are mixed, kneaded and stirred, layered (φ2mm), and then dried at 80°C for 12 hours. Cut the dry strip into about 20mm long, carbonize at 600°C for 45 minutes, then activate with water vapor at 850°C for 120 minutes, the BET specific surface area of the obtained metal activated carbon is 1130m 2 / g, the total pore volume is 1.16cm 3 / g, when the metal activated carbon is used as a capacitor electrode material, its specific capacitance is 301F / g.

Embodiment 3

[0037] Take 100g bituminous coal, 62.5gCu(NO 3 ) 2 ·3H 2 O (make a solution), mix 45g of coal tar, 0.5g of additives and an appropriate amount of water, knead and stir, layer (φ2mm), and then dry at 80°C for 12 hours. Cut the dry strip into about 20mm long, carbonize at 600°C for 45 minutes, and then activate with water vapor at 850°C for 120 minutes, the BET specific surface area of the obtained metal activated carbon is 922m 2 / g, the total pore volume is 0.95cm 3 / g, when the metal activated carbon is used as capacitor electrode material, its specific capacitance is 236F / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com