Method for improving thermoplastic plastics shaping manufacturability and capability

A thermoplastic and molding technology, applied in the field of materials, can solve problems such as molding process limitations, and achieve the effect of expanding the scope of application, improving performance, and improving molding processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Firstly, weigh the photocurable cross-linking monomer (referred to as monomer), oligomer, photoinitiator and photosensitizer according to the metering, add thermoplastics after mixing evenly, and use twin-screw extruder to shape after mixing evenly. In terms of parts by weight, the ratio of each raw material is: 20 parts of monomers, 20 parts of oligomers, 4 parts of photoinitiators, 2 parts of photosensitizers, and 60 parts of thermoplastics.

[0025] The monomer in the above formula is ethoxylated trimethylolpropane triacrylate (EO 3 -TMPTA), the oligomer adopts bisphenol A epoxy diacrylate, the photoinitiator adopts the liquid triaryl hexafluorophosphate sulfonium salt mixed with single salt and double salt, and the photosensitizer adopts 2,3-dihydro-1 -Indanone, a thermoplastic made of polycarbonate pellets.

Embodiment 2

[0027] Except that each raw material proportioning has following change, other is with embodiment 1.

[0028] In parts by weight, the ratio of each raw material is: 10 parts of monomer, 10 parts of oligomer, 2 parts of photoinitiator, 1 part of photosensitizer, and 80 parts of thermoplastic.

Embodiment 3

[0030] In terms of parts by weight, the ratio of each raw material is: 20 parts of monomers, 20 parts of oligomers, 4 parts of photoinitiators, 2 parts of photosensitizers, and 60 parts of thermoplastics.

[0031] In this example, the monomer is trimethylolpropane trimethacrylate (TMPTMA), the oligomer is bisphenol A epoxy diacrylate, and the photoinitiator is liquid triaryl six The sulfonium fluorophosphate and 2,4,6-trimethylbenzoyl-diphenylphosphine oxide (TPO) have a mass ratio of 1:1, and polycarbonate pellets are used as thermoplastics. Others are with embodiment 1.

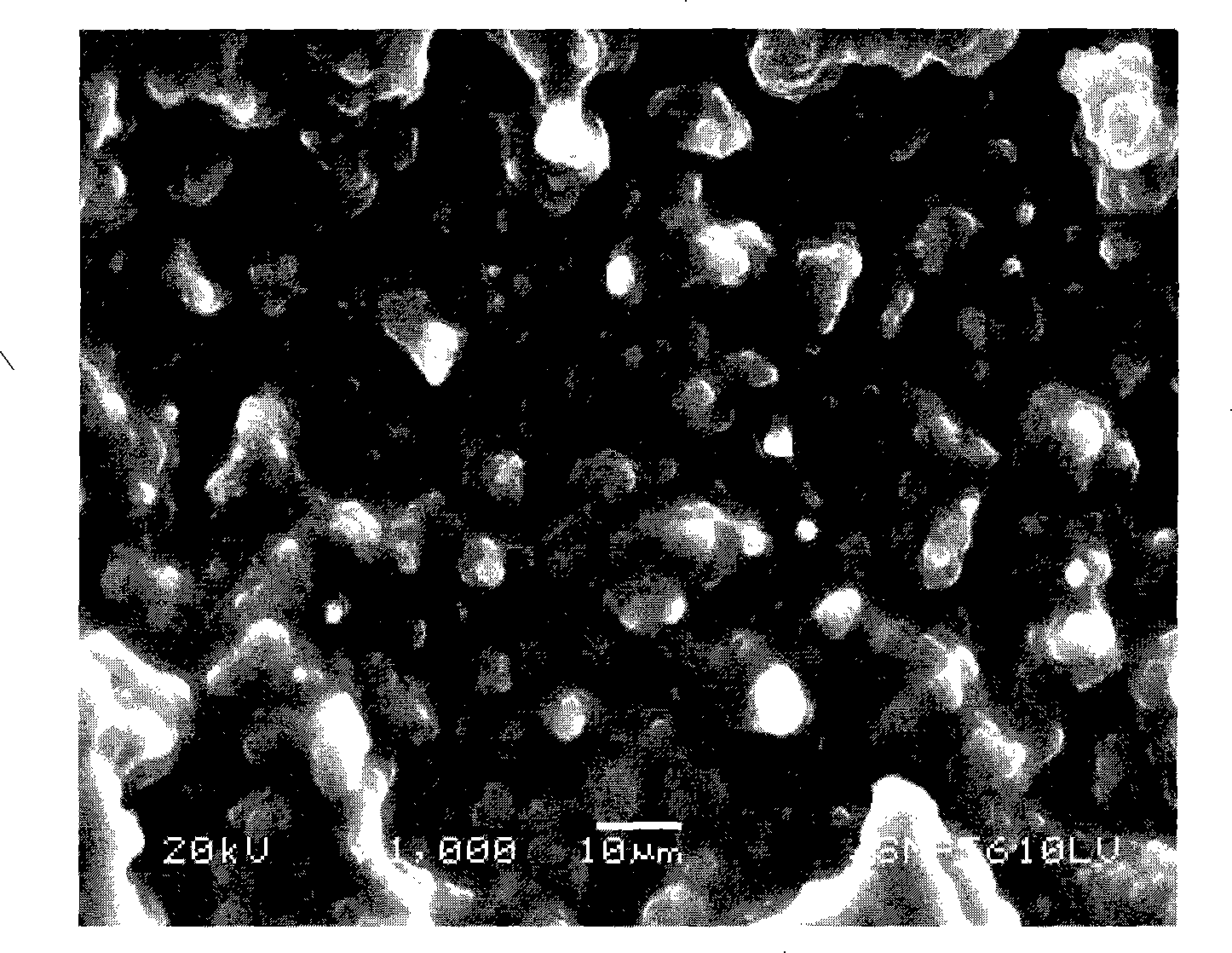

[0032] The obtained thermoplastic composite material of this example, its scanning electron microscope picture is as follows figure 1 As shown, where: the white area is the thermosetting particles formed by the polymerization of monomers and oligomers. It can be seen from the figure that the thermosetting is uniformly dispersed in the continuous phase polycarbonate matrix.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com