Hydrophobic treatment method of electrode material

An electrode material, hydrophobic treatment technology, applied in battery electrodes, electrode manufacturing, nanotechnology for materials and surface science, etc. Easy to scale and use, good repeatability and consistency, green and economical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Step 1: Dissolve polymethyl hydrogen siloxane in n-hexane, wherein polymethyl hydrogen siloxane is 0.5 g and n-hexane is 50.0 g;

[0036] Step 2: Put 10.0g of LiNi at room temperature 0.8 Mn 0.1 Co 0.1 O 2 Join in the n-hexane solution of above-mentioned polymethyl hydrogen siloxane, stir and mix 10min at 300rpm speed;

[0037] Step 3: Put the mixed solution after mixing into a water bath at 80°C for continuous heating and stirring for 4h;

[0038] Step 4: After the reaction mixture is suction filtered, powder is obtained, which is placed in a 90°C vacuum drying oven to remove residual solvent.

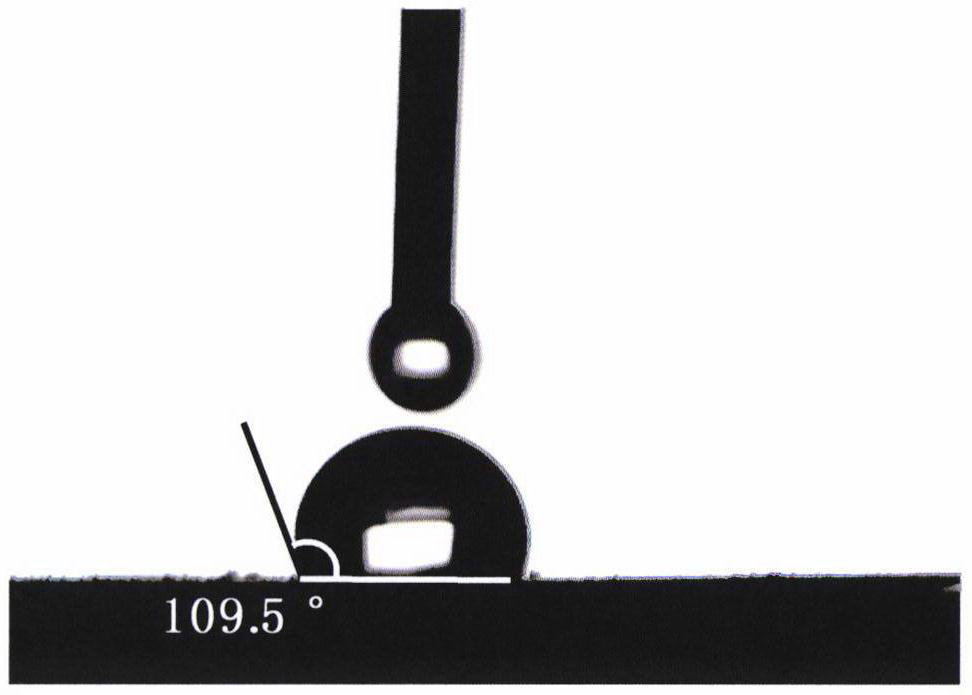

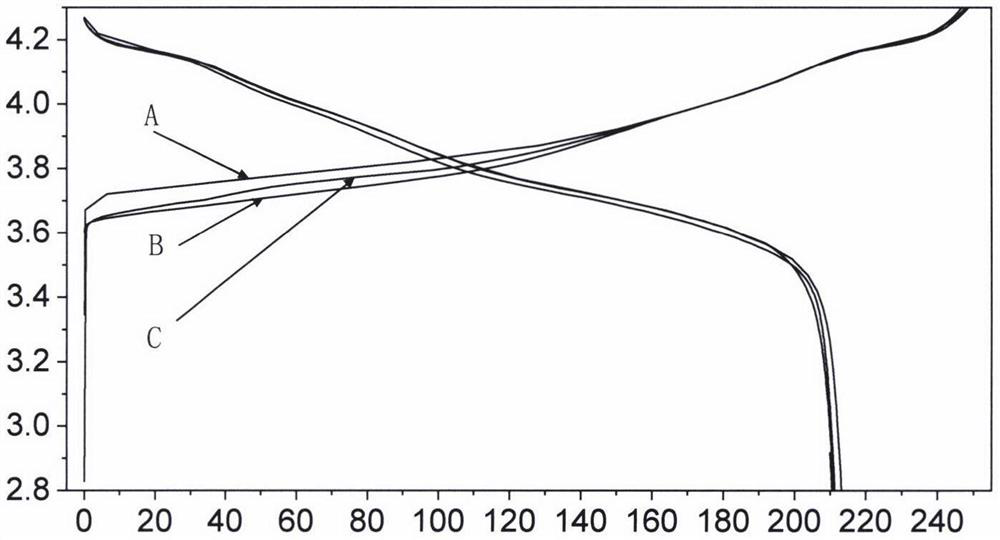

[0039] The contact angle test of the obtained hydrophobic high nickel ternary cathode material powder was carried out by using the optical method contact angle / interfacial tension JY-82B Kruss DSA contact angle tester from KRüSS Company in Germany. like figure 1 As shown, the water contact angle is 109°. The obtained hydrophobic high-nickel ternary cathode material powd...

Embodiment 2

[0044] Step 1: Dissolve polydimethylsiloxane in acetone, wherein polydimethylsiloxane is 0.5g and n-hexane is 50.0g;

[0045] Step 2: Put 10.0g of LiNi at room temperature 0.8 Mn 0.1 Co 0.1 O 2 Add to the acetone solution of the above-mentioned polydimethylsiloxane, stir and mix at a speed of 300rpm for 10min;

[0046] Step 3: Put the mixed solution after mixing uniformly into a water bath at 80°C for continuous heating and stir at a speed of 300rpm for 4h;

[0047] Step 4: Suction filtration of the reacted mixed solution to obtain powder, which is put into a 100°C vacuum drying oven to remove residual solvent.

[0048] LiNi after hydrophobic coating 0.8 Mn 0.1 Co 0.1 O 2 The reversible capacity of 189.9mAh g -1 , the capacity retention rate was 70.7% after 300 cycles of 1C current. The reversible capacities of the coated cathode material are 181.7 and 170.8 mAh g after 72 h and 120 h storage in a humid environment -1 , the capacity retention rate after 300 cycles a...

Embodiment 3

[0050] Step 1: Dissolve polymethyl hydrogen siloxane and hydroxyl-terminated polydimethylsiloxane in n-hexane, wherein polymethyl hydrogen siloxane 0.5g, hydroxyl-terminated polydimethylsiloxane 1.0g, n-hexane 50.0g;

[0051] Step 2: Put 10.0g of LiNi at room temperature 0.8 Mn 0.1 Co 0.1 O 2 Add 0.03g of nano titanium dioxide to the above-mentioned n-hexane solution of polymethylhydrogensiloxane and hydroxyl-terminated polydimethylsiloxane, and stir and mix at 200rpm for 10min;

[0052] Step 3: Put the mixed solution after mixing uniformly into a water bath at 80°C for continuous heating and stir at a speed of 300rpm for 4h;

[0053] Step 4: Suction filtration of the reacted mixed solution to obtain powder, which is put into a 90°C vacuum drying oven to remove residual solvent.

[0054] LiNi after hydrophobic coating 0.8 Mn 0.1 Co 0.1 O 2 The reversible capacity of 211.3mAh g -1 , the capacity retention rate was 82.5% after 1C current cycle for 300 times. The rever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com