Single-bed self-heating type thermal decomposition gasification combustion reactor and thermal decomposition gasification combustion method

A technology of pyrolysis gasification and reactor, which is applied in the manufacture of combustible gas and petroleum industry, etc. It can solve the problems of poor economy, inability to be used as synthesis gas, and difficulty in controlling the heat carrier circulation, etc., and achieves compact structure and good industrial application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

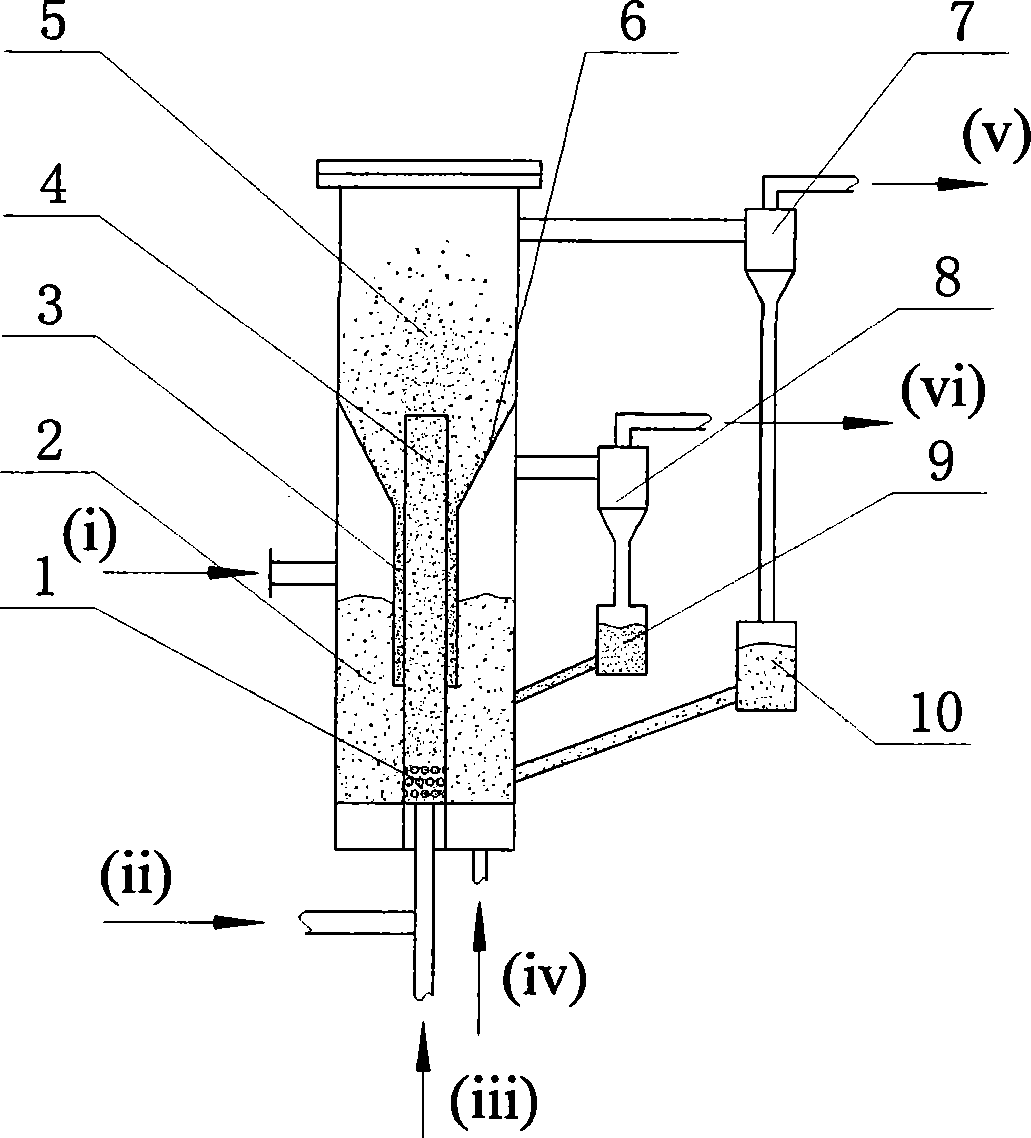

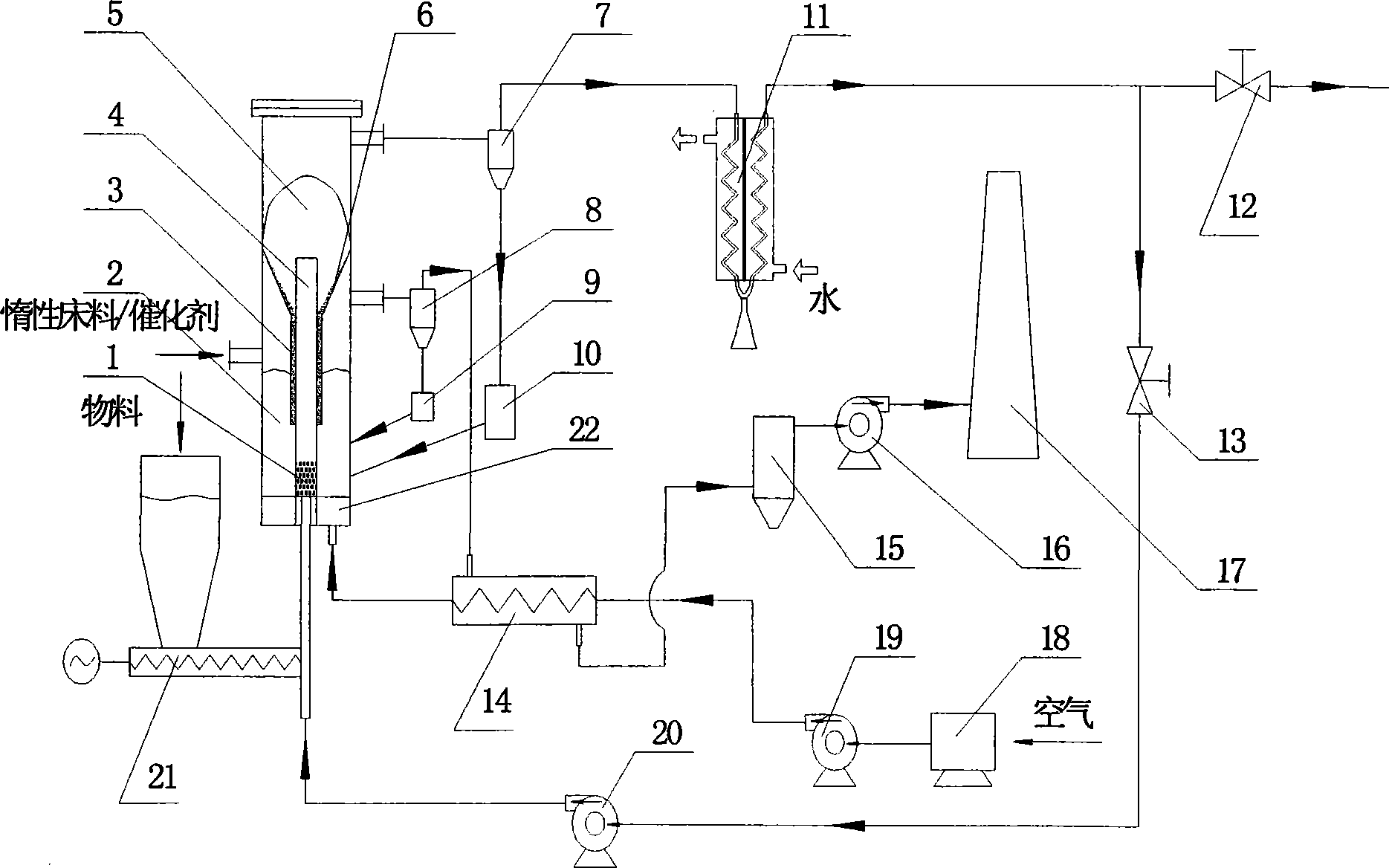

[0014] The single-bed self-heating pyrolysis gasification combustion reactor uses a partition plate 6 to divide the reactor body into the lower combustion bed 2 and the upper pyrolysis bed 5; the guide pipe 4 is arranged in the center of the reactor to connect the lower combustion bed 2 and the upper The pyrolysis bed 5 is provided with an entrainment hole 1 at the lower part of the guide pipe 4, and the entrainment hole 1 is connected with the reactor bottom inlet ii at the bottom of the reactor and the pyrolyzed non-condensable gas inlet iii, and the biomass or coal as a material The inlet ii at the bottom of the reactor is pneumatically conveyed to the guide pipe 4 by the pyrolysis non-condensable gas iii; the gap between the partition plate 6 and the guide pipe 4 forms the dipleg 3; the upper part of the pyrolysis bed 5 is connected to the product gas outlet v, The upper part of the combustion bed 2 is connected to the combustion flue gas outlet vi, the middle part of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com